Bandsaws

TALK TO A SPECIALIST

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

EU Sales

Fast EU Delivery

Worldwide

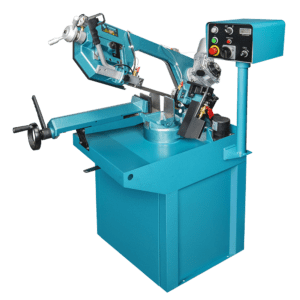

Global ShippingA bandsaw for metal is one of the important tools in most industrial factories because it cuts a wide variety of materials some of the most common being metal, wood, and plastic.

Metal Band Saws are very versatile and make a variety of cuts, including straight cuts and angled cuts thus making them a valuable tool for a variety of industrial applications within the Metalworking, Engineering and Fabrication environments being used to all profiles of material including metal bars, tubing, pipes, extrusions, and other metal objects.

The Specific Benefits of using a bandsaw in an industrial factory include Accuracy, Speed, and Versatility.

- Accuracy: Band saws when properly maintained and set up, make very accurate cuts, which is important for many industrial applications.

- Speed: Band saws can cut a wide variety of materials such as steel, mild steel, aluminium, copper, brass, titanium and many other materials quickly, saving time and money in industrial production.

- Versatility: Band Saws for Metal can be used to cut a variety of materials with straight or mitred cuts making them a valuable tool for all industrial applications.

Overall, band saws are an important tool in many industrial factories. They are versatile, accurate, and safe, which makes them a valuable asset for a vast variety of industrial applications.

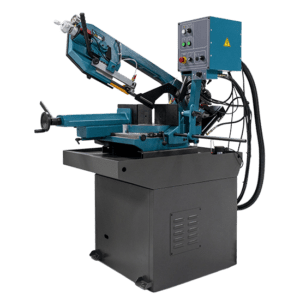

What are the important features to keep in mind when purchasing a Band Saw for Metal?

- Maximum Cut Diameter at 90 degrees: This is the largest diameter of material that the bandsaw can cut. This capacity will often vary based on the profile of material for example round or rectangle stock.

- Maximum Mitre Cut: This the maximum angle cut or non-straight cut the bandsaw can cut.

- Maximum Cut Capacity at 45 and 60 degrees: This is the largest diameter of material that the bandsaw can cut when the saw head is rotated to 45 or 60 degrees.

- Bandsaw Blade Width and Thickness: The bandsaw blade is a very important part of the machine, and it should be made of a material that is compatible with the type of metal you will be cutting. Width and Thickness determine the rigidity of the blade during the cutting operation.

- Bandsaw Bow or Head Construction: The bandsaw bow, or often referred to as “the head” should manufactured from durable materials and with a rigid design structure. Bows are either cast or manufactured.

- Bandsaw Blade Guides, Rollers, or both: The bandsaw blade is guided as it turns either with guides or rollers and there is often a combined mechanism. It is important to keep the bandsaw blade travelling straight through the cut and guides and rollers carry out a large proportion of this job.

- Bandsaw Speed Adjustment: The bandsaw speed should be adjustable to allow the operator to choose the correct bandsaw blade rotation speed for the type of metal being cut. This works in conjunction with the bandsaw blade configuration.

- Bandsaw Descent Mechanism: Metal bandsaw mitres can have a variety of mechanisms that control the descent speed of the bow saw head. The descent mechanisms can be manual user operated, pneumatic hydraulic, hydraulic, motor driven, or servo servo driven. Most standard industrial bandsaws will have a manual or pneumatic descent mechanism, and other descent mechanism will be found on high-end production metal saws.

- Bandsaw Coolant System: A coolant system helps to keep the blade cool and extend its life, and it is especially important when cutting ferrous metals, but not all saws come with a coolant system. Make sure to understand what applications require coolant to be used.

In addition to these features, there are a number of other factors to consider when choosing a bandsaw for metal, such as the physical size of the machine, the type of power it uses, and the price. It is important to choose a bandsaw that is the right size for your needs and that has the features you require. If you need assistance in determining the correct bandsaw for your application, please contact The Workshop Press Company UK at 0800 999 1090 or at info@workshoppress.co.uk.