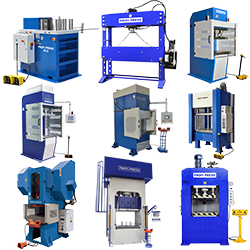

Hydraulic Presses

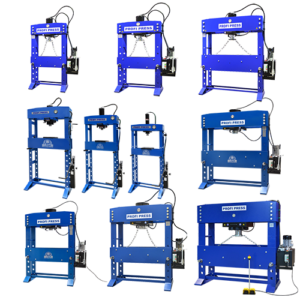

At Workshop Press, we offer an extensive range of hydraulic presses, in which all categories are shown below. All presses are available in various sizes, frameworks, control sets, and tonnages. Each press is customisable and configurable to meet the customer’s specific applications and needs.

One of the most basic and common hydraulic press categories is the Workshop Press or otherwise known as an H-Frame Press. The H-Frame press can be reasonably accurate. But are mostly designed to deliver a prescribed tonnage at a certain location for an instant.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

EU Sales

Fast EU Delivery

Worldwide

Global Shipping-

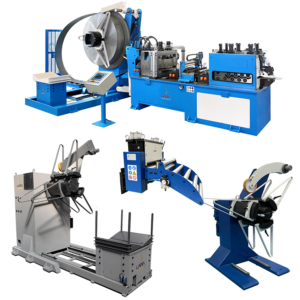

Coil Feeding Systems (8)

-

Press Brakes (5)

-

Deep Drawing Presses (7)

-

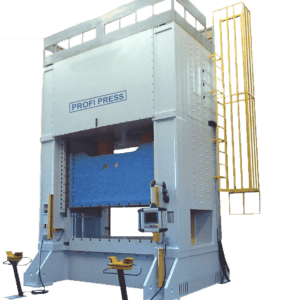

Double Column Mechanical Presses (10)

-

Motorised Workshop Presses (17)

-

Horizontal Press Brakes (21)

-

Horizontal Press Brake Tools (2)

-

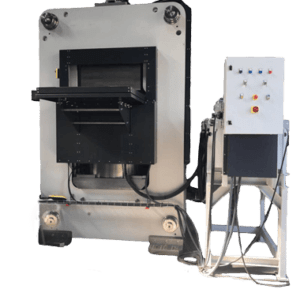

Production Hydraulic Presses (7)

-

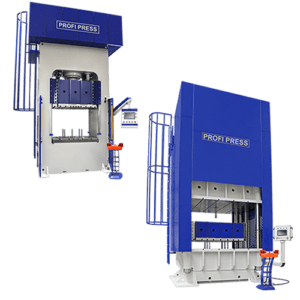

Four Column Hydraulic Presses (8)

-

Hydraulic Punching Machines (4)

-

Special and Custom Presses (15)

-

Manual Workshop Presses (4)

-

Roll Frame Portal Presses (4)

-

Roll Frame Portal Presses (3)

-

Beam Cambering Presses (3)

-

Broaching Hydraulic Presses (2)

-

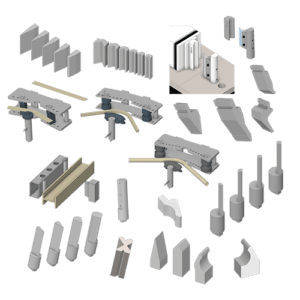

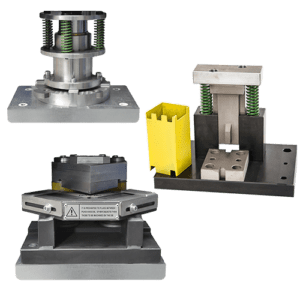

Accessories - Presses & Punching (49)

Hydraulic presses come in a variety of shapes and sizes, and all are defined by category and tonnage. Each press category offers a variety of options that can be added to the base press such as limit switches, NC controls, CNC controls, locking mechanisms, tonnage top up, safety systems, and system integration.

Although “hydraulic press” is the correct spelling and phrase to use when describing industrial hyraulic presses, many people search the internet for hydralic press, or hydrolic press. Any way you get to The Workshop Press Company website, you are in the right spot for industrial presses.

An industrial hydraulic press is a machine that uses hydraulic power to exert a large force on an object. It is typically used for metalworking but can also be used for other a variety of other applications.

A hydraulic press consists of a piston that is housed inside a hydraulic cylinder that when the hydraulic pumping system is activated the cylinder is filled with oil which forces the piston to move. The amount of force that the piston exerts is determined by the pressure of the oil and the area of the piston.

Industrial hydraulic presses are very powerful and range in tonnage from 1 ton all the way up to 100,000 tons or more making them ideal for a wide range of applications, such as Metalworking and Metal Stamping. Hydraulic presses are used to stamp, forge, and bend metal. They are also used to cut and shape metal.

Hydraulic presses are very versatile machines and are used in a wide variety of industries. They are a valuable machine tool for manufacturers, and they play an important role in the production of many everyday products.

A bit more about Motorised Hydraulic Press uses can be seen at our blog post about Hydraulic Press Uses and Benefits.

Frequently Asked Questions related to Hyraulic Presses can be viewed HERE.

How a does motorized hydraulic press work?

Are you interested in learning how a motorized hydraulic press works? At The Workshop Press Company UK, we have the expertise to guide you. A motorized hydraulic press consists of a vertically mounted cylinder within a press framework. The cylinder, available in various configurations, contains a piston that can be raised or lowered using hydraulic force. This piston has a threaded end for attaching tools or platens.

The hydraulic cylinder is a robust metal pipe with a finely machined and polished interior. It features two ports for hydraulic fluid input and output, typically filled with hydraulic oil. One port is located at the upper end, while the other is at the lower end. The piston fits snugly inside the cylinder, aided by seals or O-rings that ensure airtightness.

To activate the hydraulic pump, oil is pumped into either the upper or lower port, depending on the desired direction. When the operator chooses to lower the piston, oil is pumped to the top valve, pushing the piston down. The oil in the lower cavity of the cylinder exits through the bottom port and returns to a reservoir tank. Conversely, when the operator selects to raise the piston, the hydraulic fluid flows from the pump through the hoses and to the bottom port, pushing the piston up. The oil in the upper cavity of the cylinder is then forced out through the upper port into the reservoir.

The hydraulic system relies on a pump to move the hydraulic oil. There are various hydraulic pumps available, including gear pumps. Gear pumps consist of two gears engaged with each other, creating moving cavities that propel the hydraulic oil in the desired direction.

To control the directional flow, a manual joystick and a directional flow valve are commonly used in industrial applications. The operator moves the joystick to determine the flow direction, as the valve’s internal sliding valve responds accordingly. Alternatively, electrical coils or solenoids can control the flow electronically. Devices such as buttons, hand buttons, foot pedals, or industrial computers (HMI) send electronic signals to the solenoid valve, which directs the oil flow based on the chosen direction. For instance, pressing the down button engages the pump, and the solenoid valve directs oil to the top of the hydraulic cylinder, forcing the piston down. Similarly, pressing the up button energizes the other side of the solenoid coil, engaging the pump and directing hydraulic oil to the bottom of the cylinder, pushing it upward. In both cases, the oil from the top or bottom cell of the cylinder returns to the main reservoir.

The pressure capacity of a hydraulic cylinder depends on factors such as the internal volume of the cylinder, power pack capacity, integrated pump, electric motor size, and various other considerations.

This brief explanation provides an overview of how a hydraulic press cylinder and system operate. If you have further questions or need assistance, please don’t hesitate to reach out to our knowledgeable staff at The Workshop Press Company UK.

Hydraulic presses are used in a wide variety of industries carrying out a limitless number of applications, including:

- Metalworking: Hydraulic presses are used to stamp, bend, and shape metal. This includes everything from making car parts to creating jewellery.

- Manufacturing: Hydraulic presses are used to assemble products, such as cars and appliances. This is because they can apply a large amount of force quickly and accurately.

- Automotive: Hydraulic presses are used to stamp, bend, and shape metal parts for cars and other vehicles.

- Aerospace: Hydraulic presses are used to bend, shape, rivet and assemble metal parts for airplanes and other aircraft.

- Oil and gas: Hydraulic presses are used in a wide variety of maintenance tasks as well as to drill wells and extract oil and gas.

- Mining: Hydraulic presses are used to break up rock and extract minerals.

- Papermaking: Hydraulic presses are used to compress paper pulp and create paper.

- Plastics: Hydraulic presses are used to mould and shape plastic products either by applying direct pressure to the plastics or by apply pressure to a mould.

- Textiles: Hydraulic presses are used to weave and dye fabrics.

- Woodworking: Hydraulic presses are used to cut, shape, mould, glue, and finish wood.

Some of the benefits of using an industrial hydraulic press are:

- They exert a large amount of force, which makes them ideal for heavy-duty applications.

- They are very versatile and can be used for a wide variety of tasks.

- They are relatively easy to operate and maintain.

- They are a safe and efficient way to perform a variety of tasks.

Benefits of Hydraulic Presses

- Consistent tonnage – Throughout the entire stroke, the press may produce its maximum pressing force. As a result, you have more control over the return location, pressure, and trip distance.

- Customisation – Even the most complicated pieces can be manufactured using these presses. To match your unique needs, we can alter an existing design or create a press specifically for you.

- Small footprint – Hydraulic presses can produce significant pressure over a surface area of only a few square inches. They therefore occupy far less space than many other industrial devices.

- Economical – Because hydraulic presses are so simple to build, they very seldom break down, which means less money is spent on maintenance. If it does break down, parts are accessible and simple to replace.

- Longer Tool Life – The application, not the press, is designed to fit a hydraulic press tool. Additionally, overload prevention reduces tooling damage, increasing the life of the tool.

- They exert a large amount of force, which makes them ideal for heavy-duty applications.

- They are very versatile and can be used for a wide variety of tasks.

- They are relatively easy to operate and maintain.

- They are a safe and efficient way to perform a variety of tasks

If you are looking for a powerful and versatile machine for your manufacturing needs, an industrial hydraulic press is a great option.

Here are some additional details about hydraulic presses:

- Hydraulic presses can be very large and powerful. Some hydraulic presses can generate up to 100,000 tons of force!

- Hydraulic presses are very precise. They can apply a force that is accurate to within a few millimetres.

- Hydraulic presses are very safe. They have built-in safety features that prevent them from being overloaded.

If you are interested in learning more about hydraulic presses, please contact our sales staff to discuss your requirements. Our professional sales team can help you determine what hydraulic press is suitable for your needs.

FAQs

What is a hydraulic press used for?

A hydraulic press is a machine that uses hydraulic pressure to compress, shape, or form objects. Hydraulic presses are commonly used in industries such as manufacturing, automotive repair, and metalworking.

What are the different types of hydraulic presses?

There are different types of hydraulic presses, including C-frame, H-frame, four-column, and custom presses. C-frame presses are compact and versatile, while H-frame presses are more rigid and can handle heavier loads. Four-column presses are used for high-capacity applications, and custom presses can be designed to meet specific requirements.

What is the capacity of a hydraulic press?

The capacity of a hydraulic press can vary depending on the make and model. It can range from a few tons to several thousand tons. The capacity you need will depend on the type of objects you will be working with and the amount of pressure required to shape or press them.

What is the difference between a hydraulic and mechanical press?

A hydraulic press uses hydraulic power to generate pressure, while a mechanical press uses mechanical force, such as a flywheel or a motor. Hydraulic presses are generally more efficient and capable of generating greater force than mechanical presses.

How do I choose the right hydraulic press for my needs?

To choose the right hydraulic press, consider the capacity you need, the type of objects you will be working with, the size and space available in your workspace, and the power source you prefer. Also, consider the types of operations you will perform with the press, such as punching, bending, or forming. C-frame presses are a good option for smaller shops or for applications where space is limited. H-frame presses are more rigid and can handle heavier loads. Four-column presses are used for high-capacity applications and custom presses can be designed to meet specific requirements.

What is the cost of a hydraulic press?

The cost of a hydraulic press can vary widely, depending on the make, model, capacity, and features. Prices can range from a few thousand dollars to several hundred thousand dollars. The capacity and size of the press are the main factors that affect the price, with larger and more powerful presses generally costing more.

How does a hydraulic press work?

A hydraulic press uses hydraulic pressure to compress or shape objects. It works by using a piston that moves up and down inside a cylinder. The piston is connected to a hydraulic system that generates pressure, and the pressure is used to move the piston up and down. The force generated by the piston is transferred to a tool or die that is used to shape or compress the object.