Motorised Workshop Presses

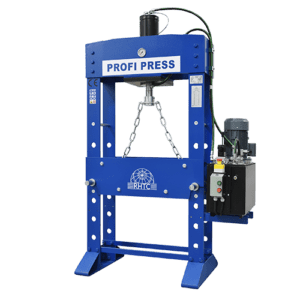

Motorised Workshop Presses from Profi-Press are manufactured in the EU with only the highest quality materials and components. They are all manufactured according to the most current machinery directives, and come in a variety of tonnages to suit your needs. Whether you’re a professional engineer or a hobbyist, a Profi-Press motorised workshop press is the perfect tool for a variety of tasks. They can be used for straightening and pressing in and out bearings, as well as for general assembly and metal forming work. Profi-Press motorised workshop presses are built to last. The casing of the press is very stable and its hydraulic system is extremely precise, whether operated electrically with the joystick or manually with the hand pump.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

EU Sales

Fast EU Delivery

Worldwide

Global ShippingMotorised Workshop Presses

Profi-Press motorised workshop presses are the perfect tool for a variety of tasks, from straightening and pressing in and out bearings to general assembly and metal forming work. They are manufactured in the EU with only the highest quality materials and components, and come in a variety of tonnages to suit your needs. Being manufactured in the EU separates our Profi-Presses from 90% of the workshop presses that are offered on the market today. There are built in the EU which is a sign of quality and craftsmanship. All offered presses are manufactured to the most current machinery directives, which means that they meet high safety standards.

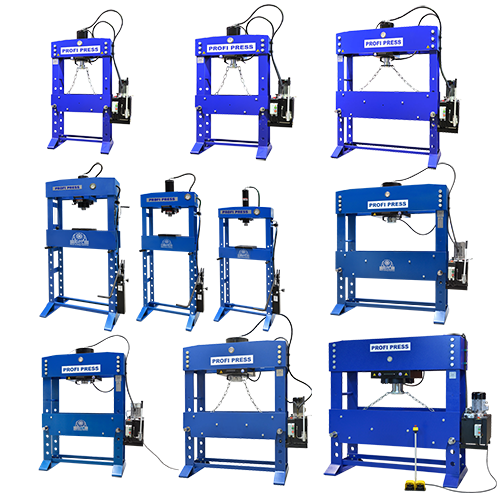

Although the most common name for these type of presses is “Workshop Press” they are generically called by many other names such as a H Frame Press, Hydraulic Bearing Press, Floor Press and we offer 2o Ton Workshop Presses and up to 100t hydraulic workshopresses. Larger 200T and 300T floor presses are also available.

The Workshop Press Company offering of workshop presses provide several common features that other press manufacturers do not provide. The moveable head, multiple operating modes, pressure fine adjustment, two changeable advance speeds, and adjustable table are just a few examples. All of these qualities enable even the most inexperienced operator to do extremely precise pressing operations.

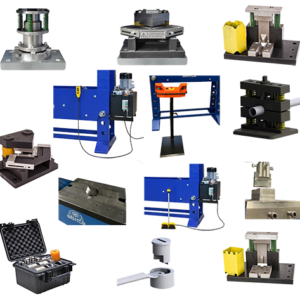

All of our motorised hydraulic workshop presses have pistons with diameters that make other workshop presses appear to be toys. The piston cap on the motorised hydraulic H Frame Presses may be removed. This enables custom tools to be attached to the piston rod’s end. Custom tools are a highly popular add-on for our clients. Other options are V-blocks, Working Tables, and Press Brake Tooling to name a few.

Whether you’re a professional engineer or a hobbyist, a Profi-Press motorised workshop press is the perfect investment for your workshop. They are built to last, with a stable casing and precise hydraulic system, and they come with a variety of features to make them easy to use, including a joystick for electric operation and a hand pump for manual operation.

If you’re looking for a high-quality motorised workshop press that will last for years to come, a Profi-Press press is the perfect choice for you.

How a Motorised Workshop Press Works

The hydraulic cylinder is the heart of a motorised workshop press and the cylinder is s a long, metal tube that contains a piston. The piston is connected to a ram, which is the part of the press that applies the force. The size of the cylinder determines the amount of force that the press can generate.

The hydraulic cylinder works by using the scientific principles of hydraulics which some people give the Ancient Greeks credit for but for industrial purposes a gentleman by the name of Blaise Pascal way back around the 1647 deserves the credit. Hydraulics is the science of using liquids to transmit force. For our purposes the liquid is hydraulic oil and in a hydraulic press cylinder, the hydraulic oil is hydraulic fluid. Hydraulic fluid is a non-compressible fluid, which means that it cannot be squeezed.

When hydraulic oil is pumped into the hydraulic cylinder, it pushes the piston down. The piston is connected to the ram, so the ram moves down as well. The force that the ram applies is equal to the pressure of the hydraulic oil multiplied by the area of the piston.

The pressure of the hydraulic oil is determined by the speed of the pump and the size of the hydraulic lines. The faster the pump runs, the higher the pressure of the hydraulic fluid. The smaller the hydraulic lines, the higher the pressure of the hydraulic fluid.

The amount of force that the hydraulic cylinder can generate is determined by the size of the cylinder and the pressure of the hydraulic fluid. The larger the cylinder, the more force it can generate. The higher the pressure of the hydraulic fluid, the more force it can also generate.

Hydraulic cylinders are a versatile tool that can be used for a variety of tasks. They are a valuable asset for any workshop or industrial setting.

Here are some additional details about how the hydraulic cylinder works:

- Piston: The piston is a long, metal rod that fits snugly inside the hydraulic cylinder. The piston is connected to the ram, which is the part of the press that applies the force.

- Hydraulic fluid: Hydraulic fluid is a non-compressible fluid that is used to transmit force in a hydraulic cylinder. For hydraulic presses it is hydraulic oil.

- Pump: The pump is used to move hydraulic fluid into the hydraulic cylinder. The pump is typically powered by an electric motor.

- Control valve: The control valve is used to direct the flow of hydraulic fluid into the hydraulic cylinder. The control valve can be used to control the speed of the press, as well as the direction of the force.

Here are some of the benefits of using a Profi-Press motorised workshop press:

- High quality materials and components

- Manufactured to the most current machinery directives

- Versatile design for a variety of tasks

- Built to last

- Easy to use with a joystick for electric operation and a hand pump for manual operation

If you’re looking for a reliable and powerful motorised workshop press, a Profi-Press press is the perfect choice for you.

Customers use motorised workshop presses for. Here are a few examples:

- Straightening and bending metal

- Pressing in and out bearings

- Fabricating metal

- Press Brake Operations

- Molding and Casting

- Metal Forming

- Machining

- Assembly work

- Repair work

- Hobbyist projects

Motorised workshop presses are versatile tools that can be used for a variety of tasks. They are a valuable asset for any workshop or manufacturing facility.

View our FAQ Page for Motorised Workshop Presses.

All our Motorised Workshop Hydraulic Presses are CE Certified and have a 2-Year warranty.