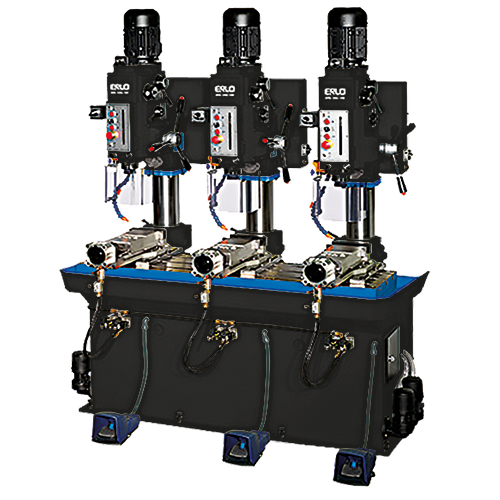

Erlo Gang Drilling Machines – Fixed Worktables for Serial Production

Product Code: ERLO-GANG-DRILL-CUSTOMDesigned for maximum productivity, Erlo Gang Drilling Machines feature fixed worktables that provide enhanced comfort and stability when clamping large or heavy parts. This design allows for seamless part handling and multiple operations without the need for repositioning.

Each setup can be customized with up to six drilling heads and different table sizes, providing unmatched flexibility for workshop requirements. Compared to traditional machining centres, these gang drills offer a cost-effective solution for high-volume production, making them ideal for industries needing rapid and repetitive operations.

Please contact for prices

- Description

- Additional Info

Designed for maximum productivity, Erlo Gang Drilling Machines feature fixed worktables that provide enhanced comfort and stability when clamping large or heavy parts. This design allows for seamless part handling and multiple operations without the need for repositioning.

Each setup can be customized with up to six drilling heads and different table sizes, providing unmatched flexibility for workshop requirements. Compared to traditional machining centres, these gang drills offer a cost-effective solution for high-volume production, making them ideal for industries needing rapid and repetitive operations.

Technical Specifications

- Drilling Capacity [mm]: 25 (per spindle)

- Spindle Stroke [mm]: 150

- Motor Power [kW]: 1.5 (each head)

- Drive Type: Gear Transmission with Adjustable Speeds

- Feed System: Automatic Hydroblock & Manual

- Feed Control: Adjustable Speed, Dual Palm Start

- Head Control: Independent or Sequential Operation

- Multi-Spindle Head: 4-Hole Drilling Attachment per Head

- Base: Heavy-Duty Cast Iron with T-Slots

- Control Panel: Integrated Palm Button Station

Key Features

- Dual SE-25 drill heads mounted on shared base

- Multi-spindle adapters drill 4 holes per head simultaneously

- Automatic feed system with Hydroblock technology

- Manual or automatic mode with dual-hand safety activation

- Adjustable gear speeds for precise material matching

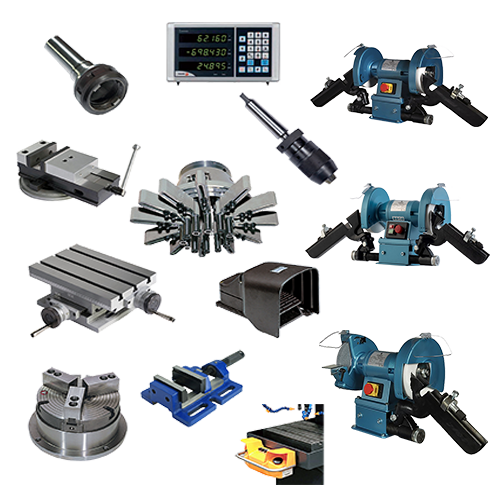

Optional Accessories

- Custom Multi-Spindle Heads for varied hole patterns

- Depth stops and adjustable work holding fixtures

- Coolant delivery system integration

- Motorized table height adjustment

- PLC integration for full automation

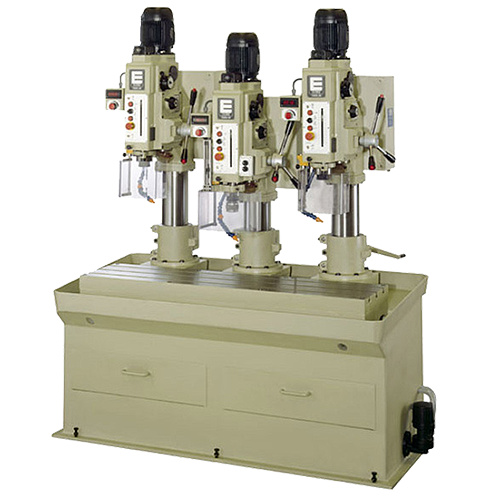

Erlo SE-25 Dual-Head Gang Drilling System Overview

This Erlo gang drilling system features two SE-25 pillar drill heads mounted on a precision-machined, heavy-duty base. Each head includes an adjustable gear transmission for fine-tuning spindle speed across various materials.

Equipped with automatic feed via a Hydro-block system, the machine offers both manual hand operation and automated control, providing maximum flexibility. Operators can engage either drill head individually or run both heads in synchronized sequence for consistent, mirrored operations.

Each SE-25 head is fitted with multi-spindle drill heads, enabling four holes to be drilled simultaneously per station — significantly increasing output. In automatic mode, feed initiation is controlled by dual-hand palm buttons for safety. Feed speed is fully adjustable, allowing for optimization based on material and tool geometry.

This setup is ideal for high-volume production environments, delivering precision, repeatability, and efficiency in batch operations.

Multi-head gang drilling machines with fixed worktables, designed for high-precision serial production and cost-effective operations.