Horizontal Press Brake Tools

Product Code: Horizontal Press Brake ToolsDiscover our extensive range of precision-engineered tools designed for horizontal press brakes, catering to the demanding needs of metalworkers, fabricators, and manufacturing engineers. Our collection includes standard tools, specialized Promecan press brake tool holders, innovative bending solutions, and accessories designed to enhance efficiency, accuracy, and versatility in metal fabrication processes.

Please contact for prices

- Description

- Additional Info

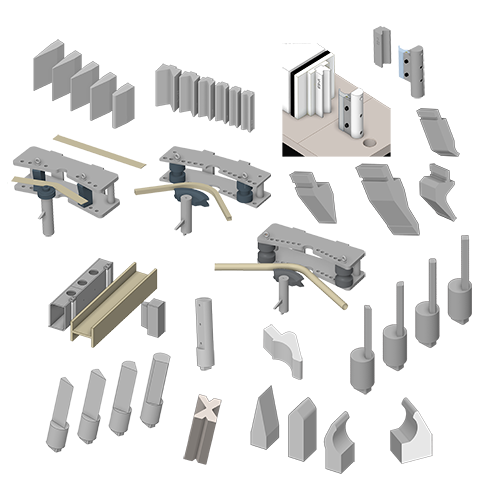

Our product lineup for horizontal press brakes includes:

- Standard Tools: Essential for basic operations, ensuring compatibility and efficiency.

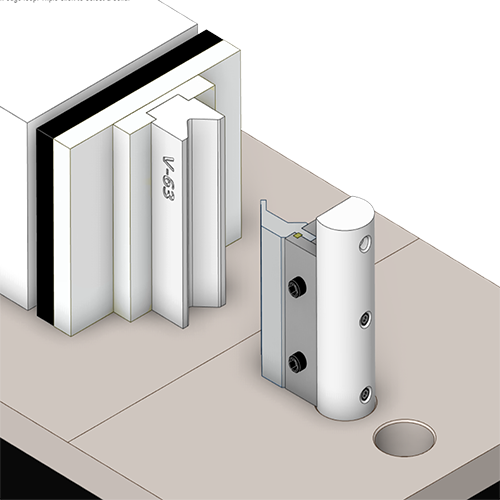

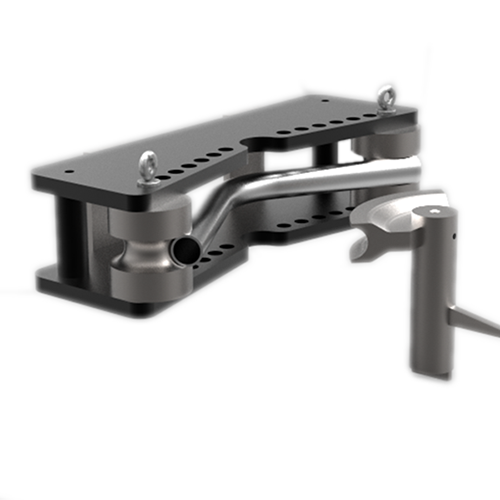

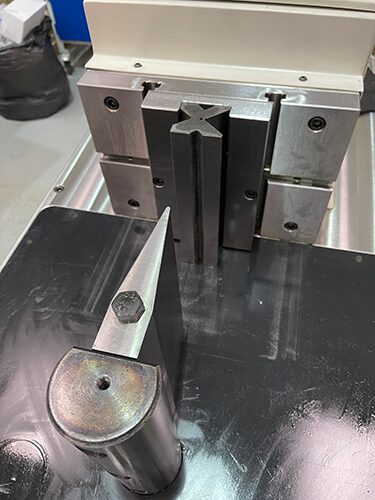

- Promecan Press Brake Tool Holders: Optimized for secure tool placement and quick changes, enhancing workflow.

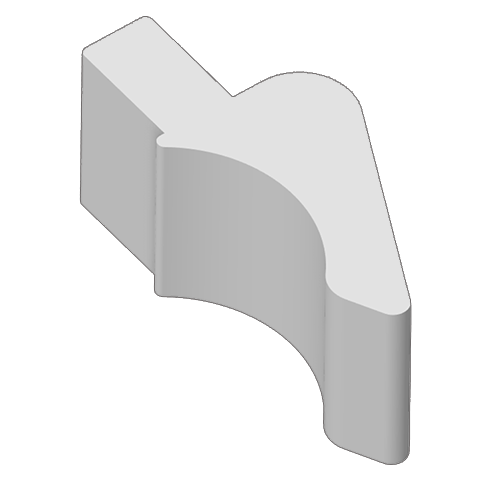

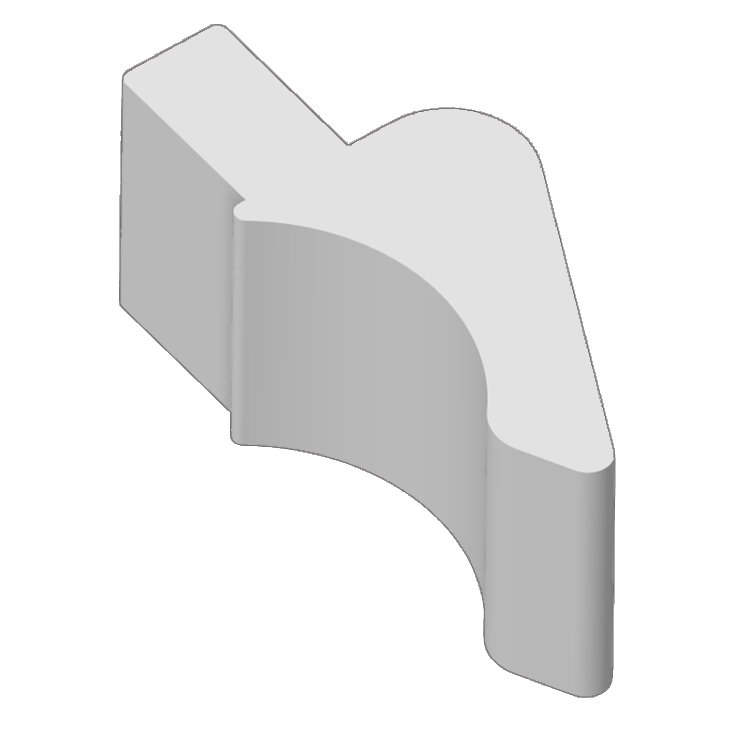

- Goose Neck Punches: Available in multiple variants for specialized bending tasks, offering versatility and precision.

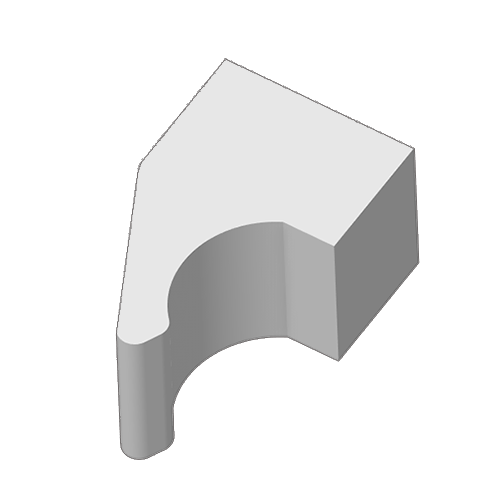

- Pipe and Tube Bending Tools: Engineered for accurate bends on various diameters, preserving material integrity.

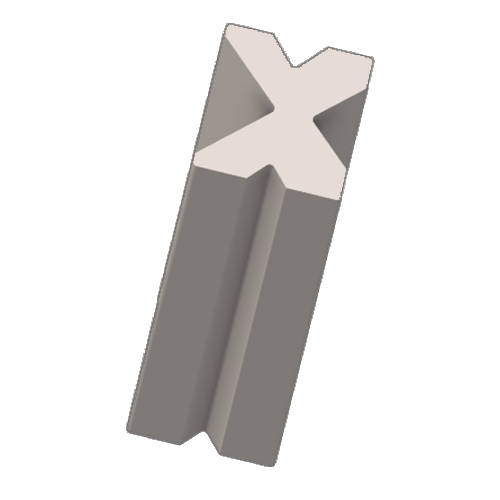

- Multi Vee Press Brake Tool & Blade Punches: Ideal for sheet metal fabrication, allowing for multiple bending angles and sizes.

- Heavy Duty Bending Tools: Designed for handling metal plates with precision and strength.

- Beam Straightening and Cambering Devices: For correcting and curving beams with high accuracy.

- Complete Ring & Circle Bending Tools: Facilitate forming solid rods, flat bars, and plates into circular shapes.

- Cutting and Punching Tools: For precise cutting and hole-punching operations in a variety of materials.

- Specialized Bending Tools: Including S Bracket bending tools, flat bar bending tools, and box section bending tools for specific applications.

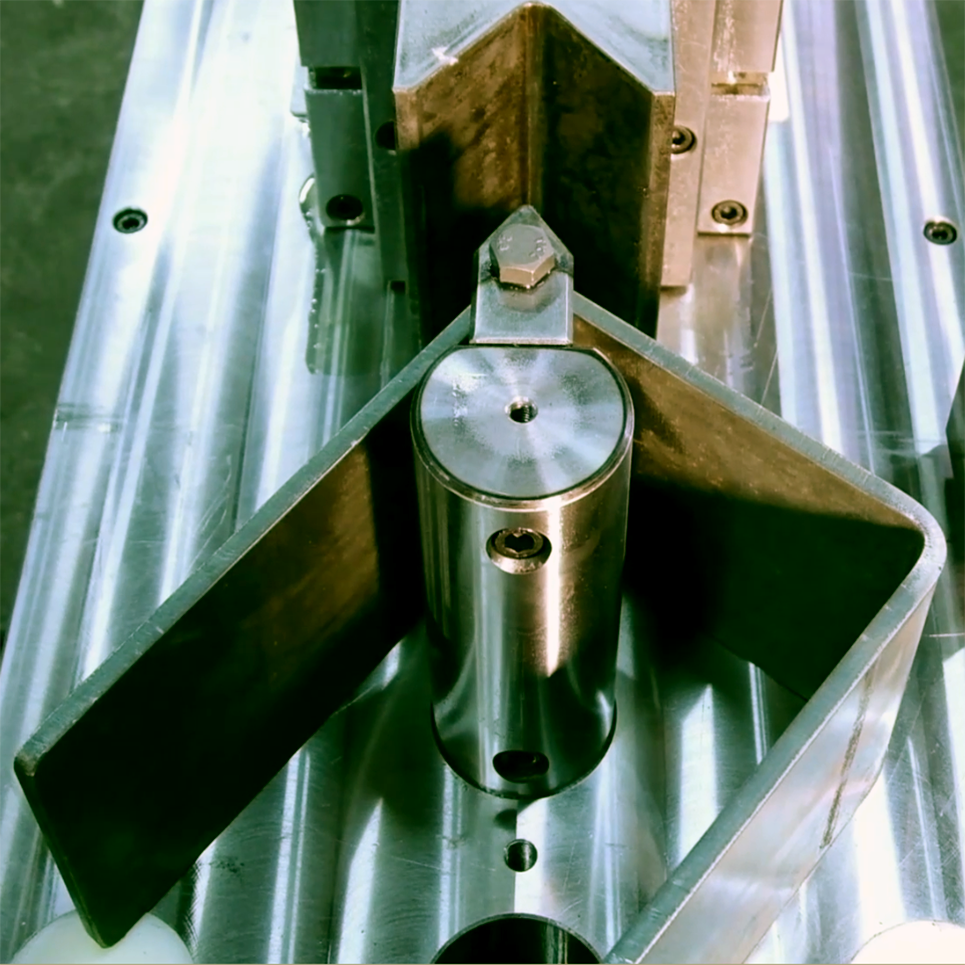

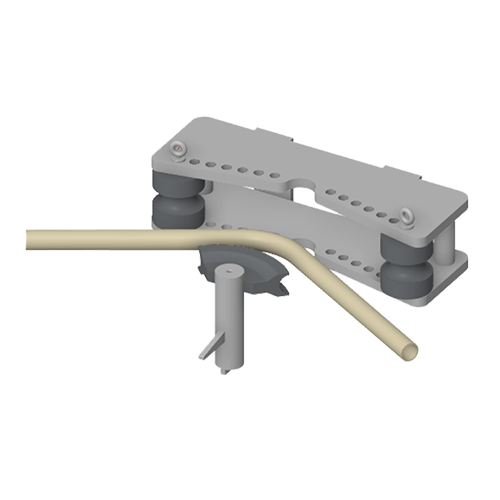

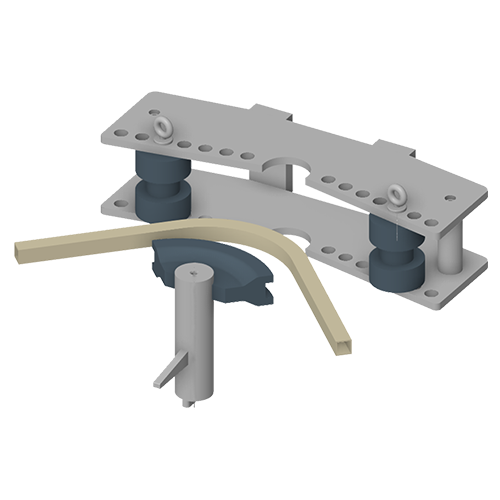

Round Tube and Pipe Bending Tool for Tubes and Pipes for such Outside Diameters as 26.7, 33.4, 42.2, 48.3, and 60.3 mm and on a wide variety of Bend Radii

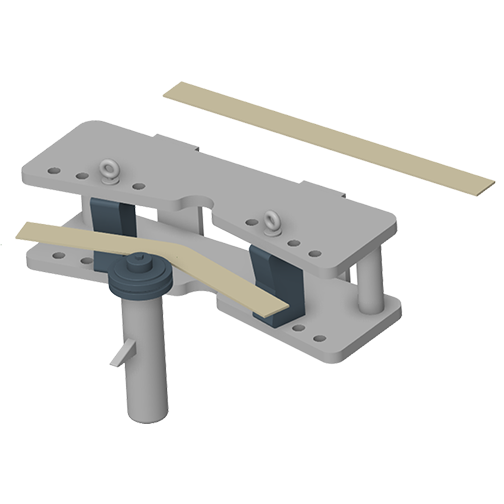

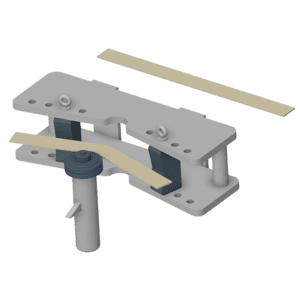

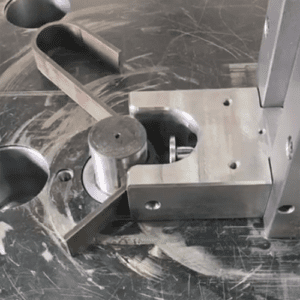

Flat Bar Bending tool for bending Flat Bar the Hard Way on a variety of Radii.

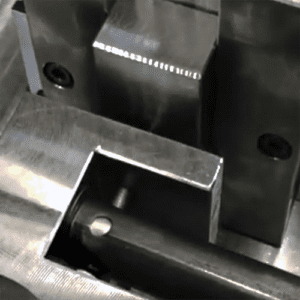

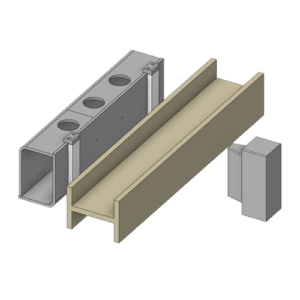

Square Tube Bending Tool for Bending Box Section and Rectangle Sections on a variety of different Radii.

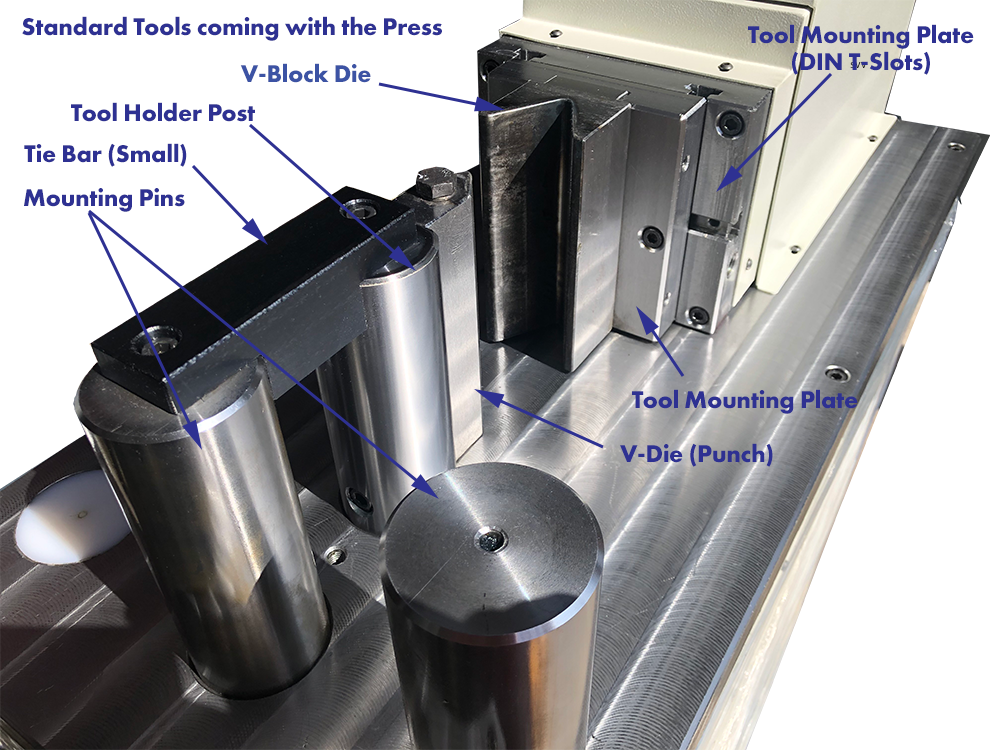

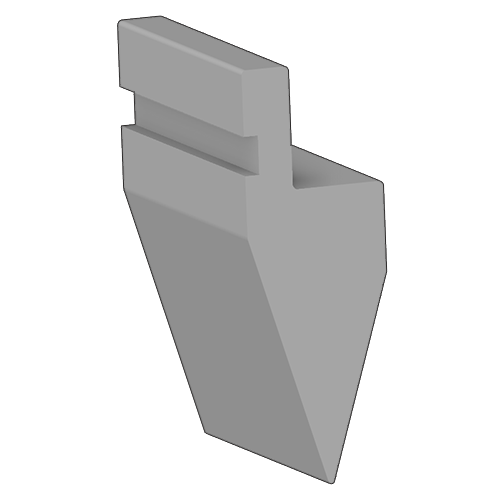

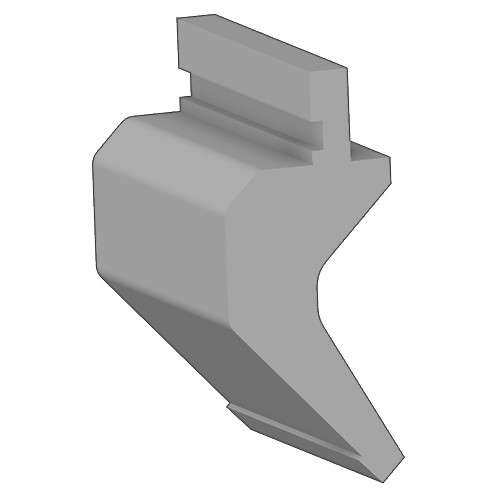

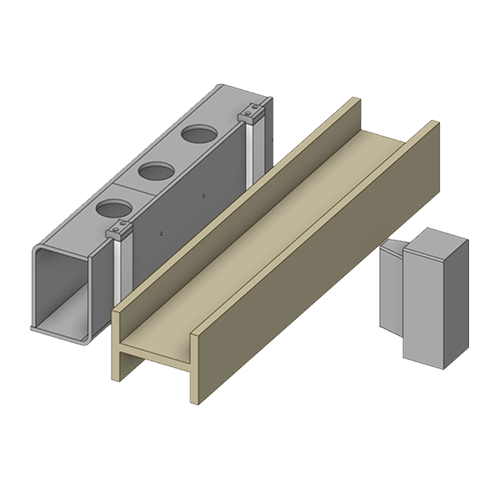

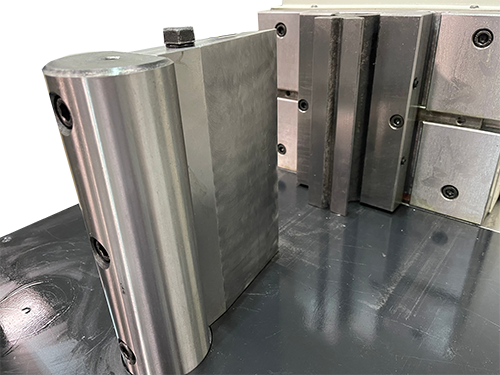

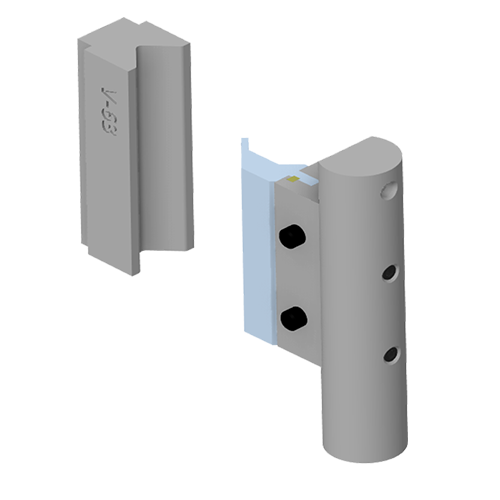

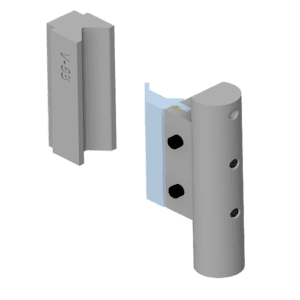

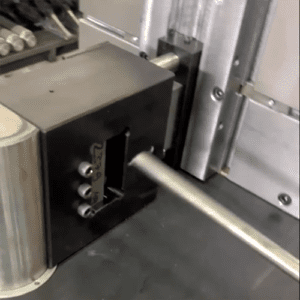

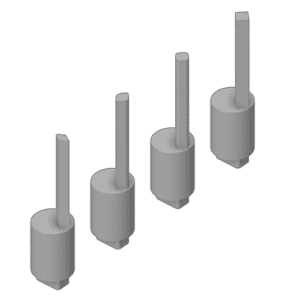

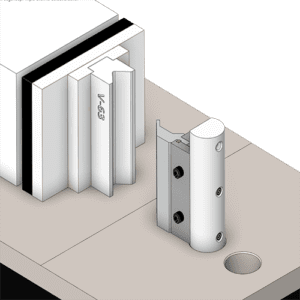

Promecam European Press Brake Tool Holder for a Horizontal Press Brake

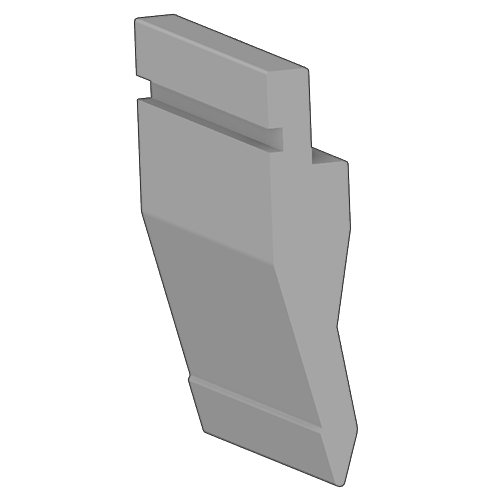

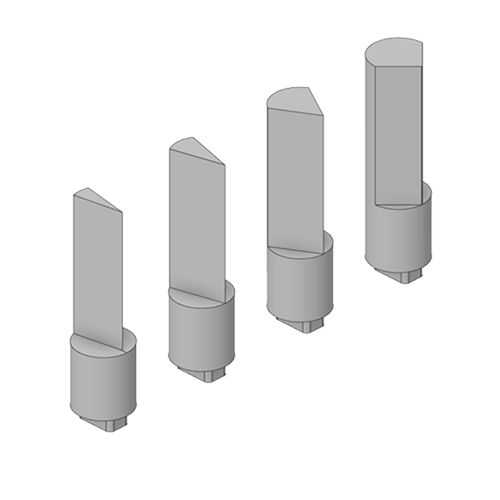

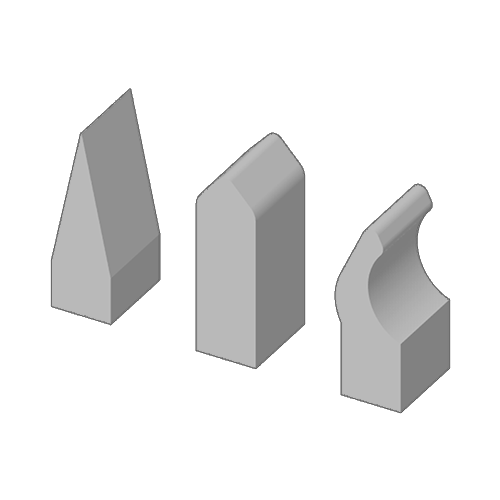

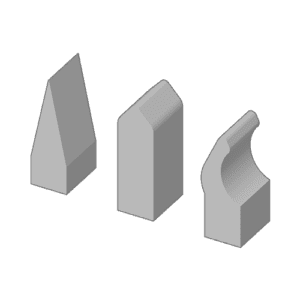

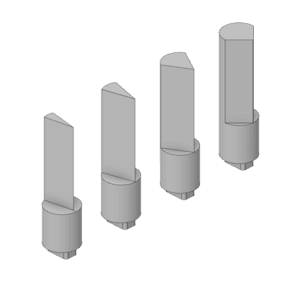

Standard and Bespoke Punches

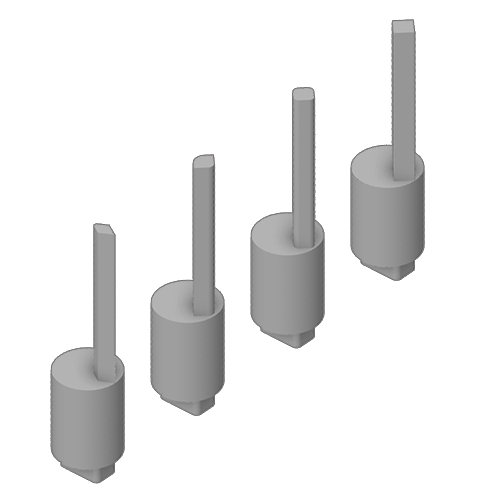

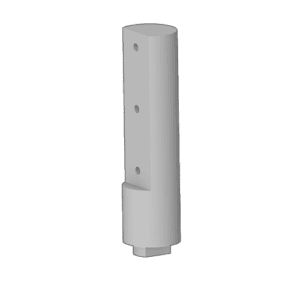

Standard and Bespoke Tool Holding Pins

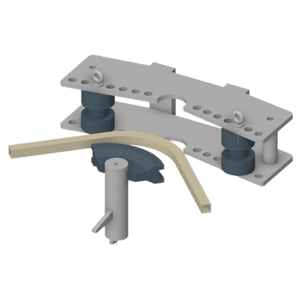

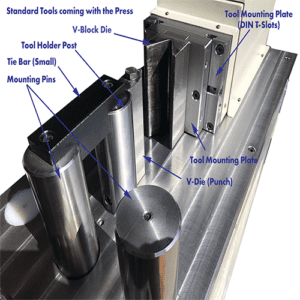

Standard Tool Set comes with 2 Posts, 1 Tool Post, V-Punch, V-Die, Tool Holder Plate, T-Slot Face Plate, and Tie Bar

Hole Punch for Tubes

S Bracket Bending Tool

f

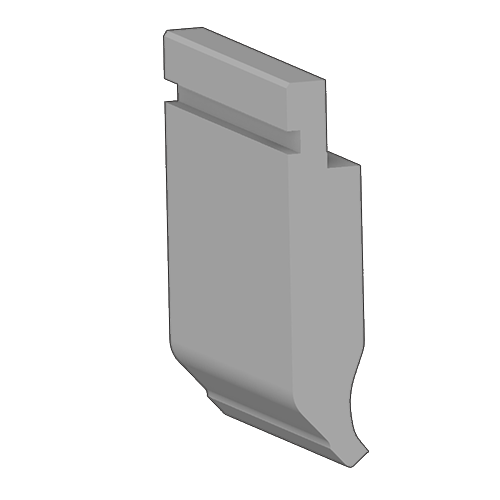

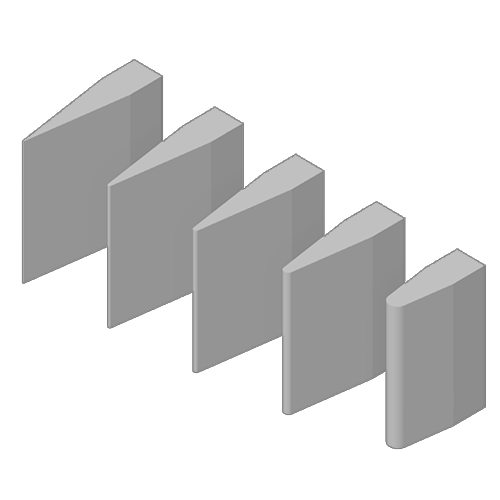

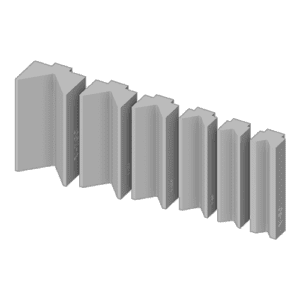

Standard and Bespoke Blade Punches & Multi-Vee

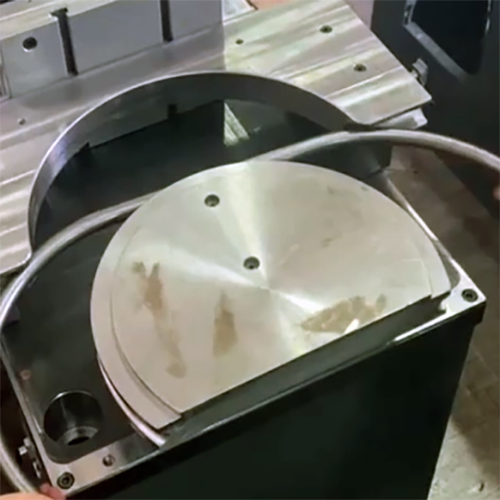

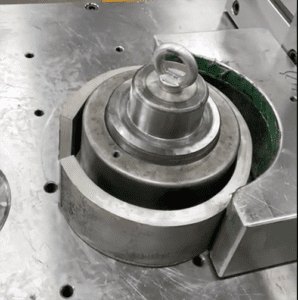

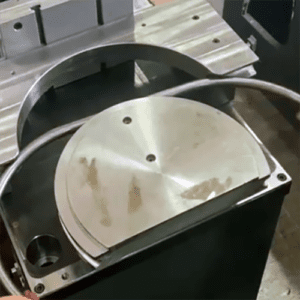

Flat Bar and Plate 360 Circle Bending Tool

Rod Cutting Tool

Solid Rod 360 Degree Circle Bending Tool

Standard and Bespoke Punches – Combination Blade Punch and Multi-Vee

Beam Straightener and Cambering Tool.

Beam Straightener and Cambering Tool

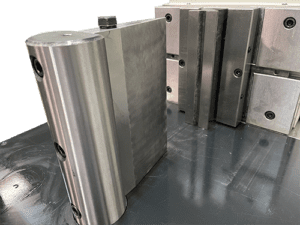

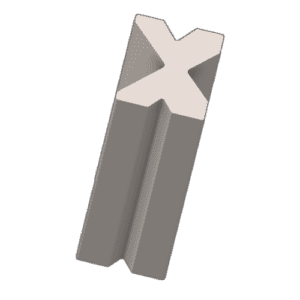

Standard and Bespoke Tool Pin Punches for Bending Heavy Plates and Bars

Standard and Bespoke Bolt Punches for bending Boxes with tight clearances

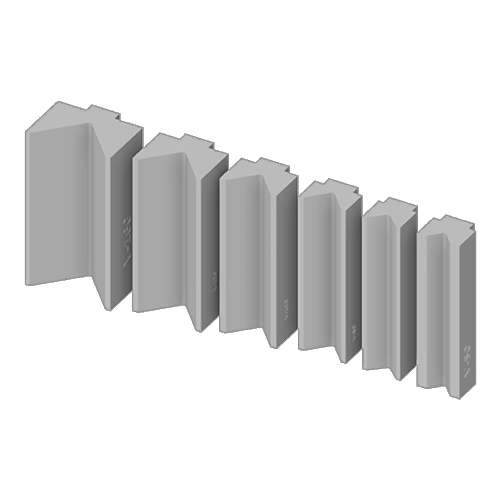

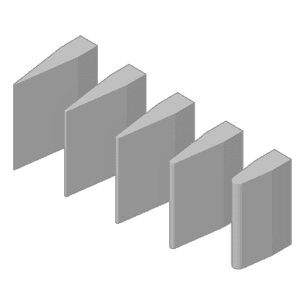

Single V-Blocks in Various Widths and Angles. Standard sizes and Bespoke Sizes are available.

Standard and Bespoke Blade Punches – Various Depths and Radii typcially used with a Multi-Vee Block

Promecam Press Brake Tool Holder for European Style Press Brake Tools.

Tube and Pipe Bending Tool available in typical sizes and in varying Radii

Multi-Vee Die for Light Gauge Sheet Metal typically used with a Knife Blade Punch

Comprehensive Catalogue of Products and Components Fabricated Using Horizontal Press Brakes

- Metal Brackets

- Angle Brackets: Support brackets for structural connections.

- Mounting Brackets: Used for securing machinery or equipment to surfaces and floors

- Enclosures

- Electrical Enclosures and Cabinets: Fixtures, Brackets, Busbars, Wire Channels and Loops.

- Machine Guards: Protective enclosures for machinery along with enclosed light curtains.

- Frames

- Chassis Frames: Structural bases for vehicles and machinery.

- Door Frames: Metal frames for doors in buildings and vehicles.

- Panels

- Facade Panels: Decorative exterior panels for buildings.

- Control Panels: Metal housings for controls and displays for machinery.

- Boxes

- Junction Boxes: Enclosures for electrical connections.

- Tool Boxes: Durable containers for storing tools.

- Flanges

- Pipe Flanges: Connectors for piping systems, providing support and strength.

- Mounting Flanges: Used for attaching objects to surfaces or machinery.

- Hinges

- Pivot Hinges: For doors and panels, allowing rotation.

- Butt Hinges: Common hinges for doors, connecting two flat components.

- Handles

- Lever Handles: For manual operation of machinery or doors.

- Pull Handles: Attached to doors, drawers, or cabinets for pulling.

- Furniture Components

- Table Legs: Support legs for tables made from metal.

- Chair Frames: Structural frames for metal chairs.

- Automotive Parts

- Bracket Supports: For securing components and drive systems within vehicles.

- Body Panels: Shaped metal parts forming the exterior of vehicles.

- Construction Elements

- I-Beams: Support beam processing used in construction.

- Reinforcement Bars: Size and Bending or Re-Bars used to reinforce concrete structures.

- Agricultural Machinery Parts

- Plow Blades: Cutting or turning soil in agriculture.

- Brackets, Arms, and Guards: Support and attaching machinery components along with safety rails.

- Railings

- Handrails: Supportive railing for stairs, balconies, mezzanines, and machinery.

- Balusters: Vertical mouldings supporting railing structures.

- Signage

- Sign Frames: Metal frames for holding sign boards.

- Bracket Signs: Signs mounted on brackets extending from surfaces.

- Lighting Fixtures

- Lamp Bases: Metal bases for standing lamps.

- Fixture Frames: Frames supporting the structure of lighting fixtures.

- Shelving Units

- Bracket Shelves: Shelves supported by metal brackets.

- Storage Racks: Metal racks for organizing and storing items.

- Art and Sculptural Pieces

- Metal Sculptures: Artistic forms created from metal.

- Decorative Panels: Intricately designed metal panels for aesthetic purposes.

- Conveyance Systems

- Conveyor Frames: Structural frames supporting conveyor systems.

- Guide Rails: Rails guiding the movement of conveyance systems.

- Ventilation Components

- Ductwork: Metal conduits for HVAC systems.

- Vent Covers: Covers for air vents, controlling airflow.

- Marine Parts

- Hull Plates: Metal plates forming the exterior of vessels.

- Deck Fittings: Metal components attached to the deck of a ship.

- Metal Gates

- Swing Gates: Gates that swing open on hinges.

- Sliding Gates: Gates that slide open horizontally.

- Metal Fences

- Picket Fences: Metal fences with vertical pickets.

- Panel Fences: Processing and Forming of Panels for pre-assembled metal panels.

Capabilities of Horizontal Press Brakes in Metal Forming

Horizontal Press Brakes (HPBs) are versatile tools capable of manipulating a wide array of metals, each selected for its unique properties and applications:

- Steel Varieties: Ranging from mild steel, perfect for general fabrication, to high-strength, low-alloy steel for structural needs, and tool steel for high-durability tooling. Stainless steel is our go-to for corrosion resistance.

- Aluminum Alloys: We work with Series 3000, 5000, and 6000 aluminum, balancing strength and pliability for diverse applications.

- Copper and Alloys: Ideal for electrical components, our HPBs handle pure copper with precision, as well as bronze and brass for both decorative and utilitarian components.

- Titanium: Utilized in aerospace and medical industries, we bend Grade 2 and 5 titanium for its exceptional strength and corrosion resistance.

- Nickel Alloys: Our equipment is adept at shaping nickel alloys for applications demanding resistance to high temperatures and corrosion.

Metal Bending Techniques and Considerations

The art of bending metals with Horizontal Press Brakes involves a nuanced understanding of material properties and the right application of technology:

- Understanding Material Properties: Acknowledging the ductility, tensile strength, and hardness of metals to apply the correct force and speed.

- Tooling Adaptation: Selecting the right tools is paramount, especially for harder metals that demand durable tooling.

- Advanced Programming: Utilizing NC or CNC technology for precise control over bending parameters, accommodating for material-specific traits like springback.

- Bending Execution: Skillfully forming metals into desired angles or shapes, with special consideration for materials prone to high springback, ensuring accuracy in the final product.

Versatility in Shaping Profiles and Structures

Our Horizontal Press Brakes excel in forming a multitude of profiles and shapes, crucial for diverse fabrication projects:

- Flat Sheets and Plates: Transforming into functional forms like pans, boxes, and brackets.

- Angles and Channels: Essential for creating supportive structures such as frames and enclosures.

- Tubes and Pipes: Catering to both round and rectangular profiles for structural and fluid transport applications.

- Bars: Bending flat, round, and square bars for a variety of uses from supports to machine components.

- Custom and Complex Shapes: Our HPBs are equipped to handle intricate designs, including serpentine bends and multi-radius curves, catering to complex geometric sections and 3D designs.

Mastery in Forming Diverse Profiles and Shapes

The capability to bend various profiles and shapes with precision underscores the advanced functionality of our Horizontal Press Brakes:

- Specialized Tooling: Custom dies and punches are essential for accurately bending unique profiles, ensuring flawless shaping without distortion.

- Control Precision: NC technology facilitates the programming of complex bends, achieving precise control over every aspect of the bending process.

- Support Systems: For complex or elongated shapes, support systems are employed to maintain alignment and prevent deformation.

- Consistent Accuracy: Advanced control systems enable the replication of specific bending operations, ensuring uniformity across batches for assembly-ready components.