Our Products

TALK TO A SPECIALIST

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global Shipping-

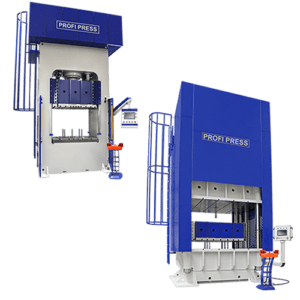

Hydraulic Presses For Sale: Industry Leading Innovation (172)

-

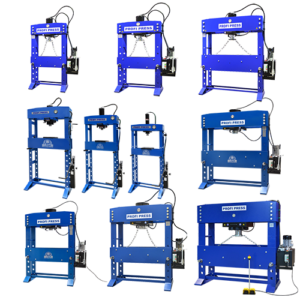

Motorised Workshop Presses (18)

-

Manual Workshop Presses (4)

-

Broaching Hydraulic Presses (3)

-

Hydraulic Punching Machines (7)

-

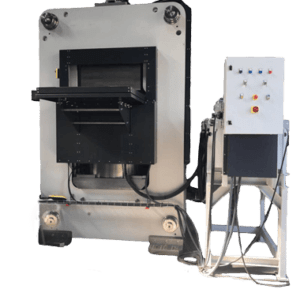

C-Frame Presses Excellence for Precision Metalworking (24)

-

Horizontal Press Brakes (23)

-

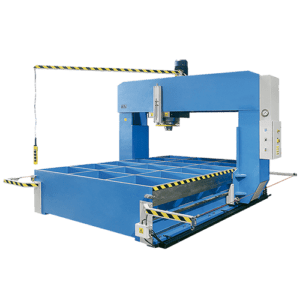

Roll Frame Portal Presses (5)

-

Roll Frame Portal Presses (5)

-

Four Column Hydraulic Presses (10)

-

Production Hydraulic Presses (9)

-

Beam Cambering Presses (4)

-

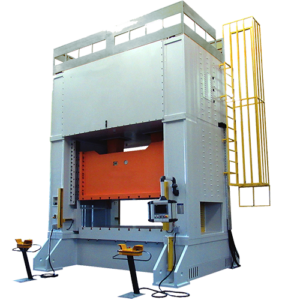

Double Column Mechanical Presses (5)

-

Deep Drawing Presses (9)

-

Heated Platen Presses (3)

-

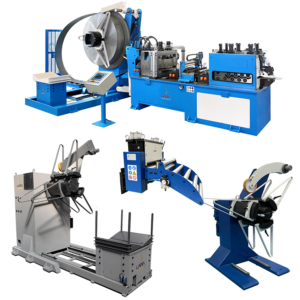

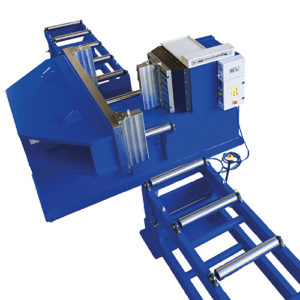

Coil Feeding Systems (8)

-

Press Brakes (6)

-

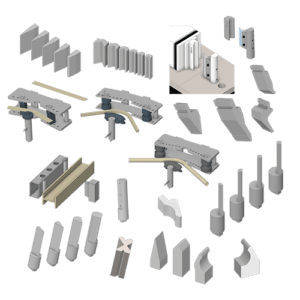

Horizontal Press Brake Tools (3)

-

Special and Custom Presses (19)

-

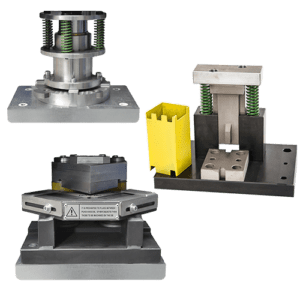

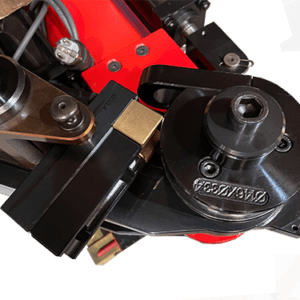

Accessories - Presses & Punching (51)

-

Band Saw Accessories (9)

-

Bending, Straightening, and Cambering Hydraulic Presses (2)

-

Feeders and Straightners (4)

-

Bandsaws (10)

-

Guillotine Shears for Metal (13)

-

Slip and Plate Rolls (5)

-

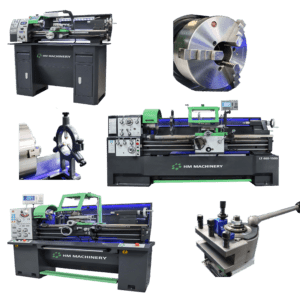

Lathes (5)

-

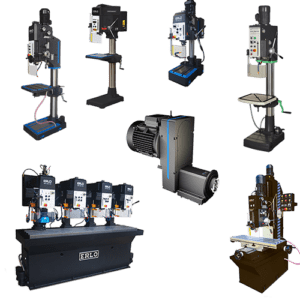

Pillar Drills - Industrial (32)

-

Pillar Drills - Professional (7)

-

Press Guarding and Safety (6)

-

Tube Benders & Tools (1)

-

Profile Bending Machines (12)

-

Belt Grinders (13)

-

Centerless Grinders/Polishers (3)

-

Notchers for Tube & Pipe (10)

-

Deburring Machines (2)

-

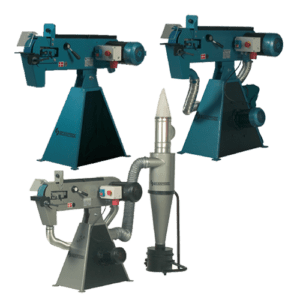

Extraction & Filter Units (6)

-

PIllar Drill and Mill Drill Accessories (29)

-

Grinders - Benchtop and Stand (6)

-

C-Frame Hydraulic Presses: Precision, Power & Performance (22)

-

All Products (23)

-

Decoilers (4)

-

Hydraulic Presses - 10 Ton (8)

-

Hydraulic Presses - 20 ton (4)

-

Expand Your Metalworking Capabilities with the Versatile 30 Ton Hydraulic Press (11)

-

Hydraulic Presses - 50 Ton (12)

-

Hydraulic Presses - 80 Ton (7)

-

Hydraulic Presses - 100 Ton (18)

-

Hydraulic Presses - 150 Ton (13)

-

Hydraulic Presses - 200 Ton (12)

-

Hydraulic Presses - 300 Ton (14)

-

Hydraulic Press - 500 Ton (10)

-

Feeders (5)

-

C Frame Mechanical Presses (3)

-

Mill Drills (4)

-

Punch Presses (28)

-

Smoke Exhausters (6)

-

Special Offers (15)

-

Tubes & Pipes End Forming (3)

-

Welding Positioners (13)

-

Rack Presses (4)

-

Profile Bender Tooling (37)