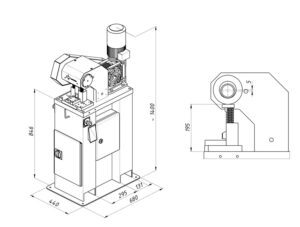

Mechanical Punching Machine • Profi Punch 10 TON • 35 Strokes per Minute

Product Code: PPP10001Discover the RHTC Profi Punch 10, a state-of-the-art 10-ton punching machine designed for precision and versatility. This machine is the epitome of metalworking excellence, perfect for punching, bending, and cutting metal, especially sheet metal.

Some of the Key Features include:

Versatility: Whether you're looking to punch holes in metal sheets, bend them, notch corners, or create round or square holes, this punching machine for metal has got you covered.

Performance: With a working pressure of 10 tons and a stroke speed suitable for production, it guarantees precision in every task. The Profi Punch 10 has a fixed stroke.

A Wide Variety of Optional Tools: Equipped with tools for corner notching, round and square punching, rod cutting, and tube drain hole punching. Custom tools are also available.

Technical Parameters Suitable for Industrial Production:The machine has an average output of 1600 pcs./h in automatic mode, a motor rotational speed of 1420 rpm, and a pressing force of 10 tons. Its overall dimensions are 680mm x 1214mm x 440mm, and it weighs 190 kg.

Safety and Ease of Operation: The machine offers a manual and automatic modes, and is CE certified and built according to the most recent directives.

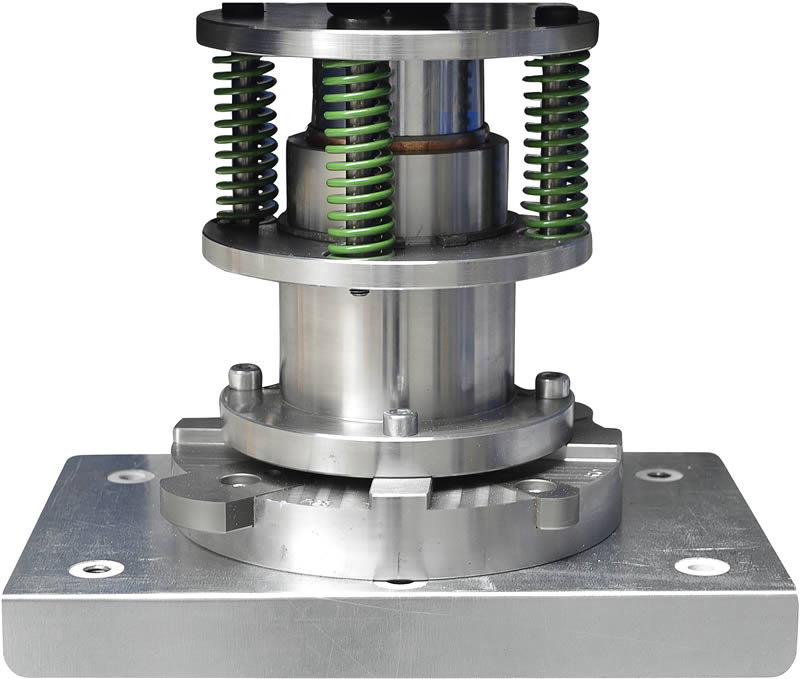

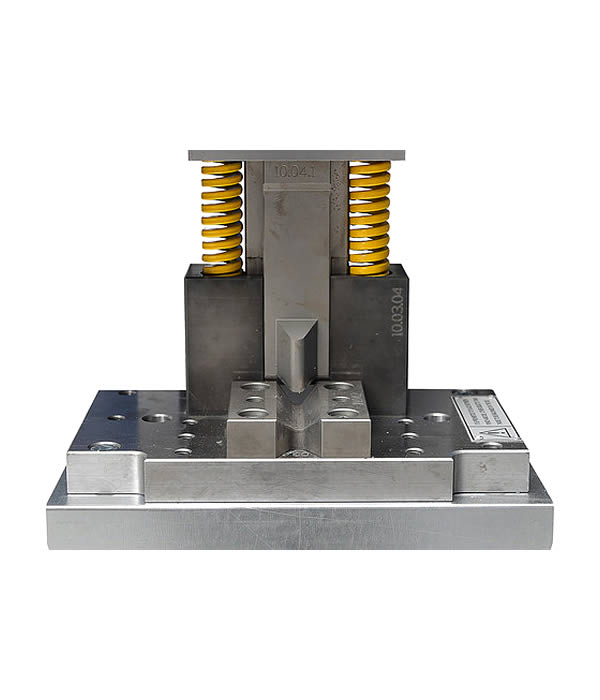

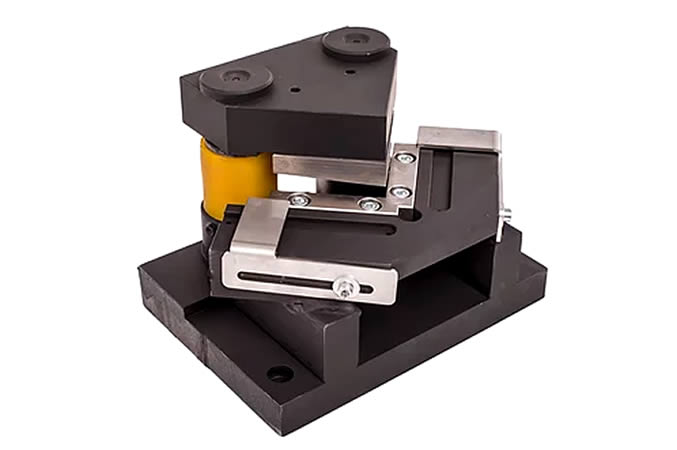

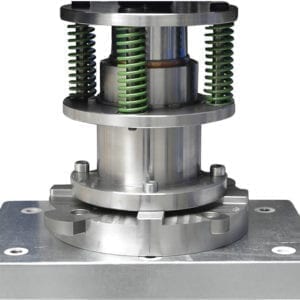

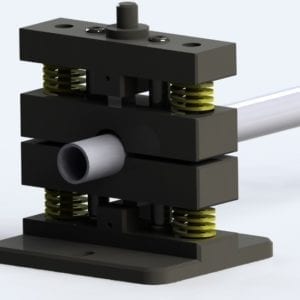

Simple Design: The Profi Punch 10 is characterized by its durable and simple design, ensuring easy operation and reliability. Its working system comprises a moving punch set and an immobile die. The machine's body is anchored to a base, and it features a drawer for collecting punched elements. It also comes with an electrical box with a manual switch, an E-Stop button, and a foot pedal switch which suits volume production.

*** OPTIONAL TOOLS are displayed in the Gallery. These are not included. ***

Please contact for prices

- Description

- Additional Info

Technical specifications

- Pressure force [tn]: 10

- Motor power [kW]: 2.2

- Shaft Rotation [rpm]: 35

- Single work cycle of punch [sec]: 1.7

- Stroke [mm]: 10

- Vertical Daylight [mm]: 195

- Table-Front to Back [mm]: 208

- Table-Frontal [mm]: 340

- Power Requirement: 400V, 3-Phase, 50 Hz

- Average output [punches/hour]: 1600

- Power Requirment: 400V, 50 Hz, 3-Phase

- Noise Level [dB]: 60

- Total length [mm]: 680

- Total width [mm]: 440

- Total height [mm]: 1214

- Weight [kg]: 190

Features

- Punches sheets up to 4 mm

- Manual & Automatic modes

- 1600 punches per hour in automatic mode

Interchangeable punch tools, for example:

- Corner wedge shaped punch

- Pipe cutter for perpendicular pipe

- Slotted hole punch

- Corner rounding notcher

- Corner cutting notcher

- Hole puncher for pipes

- Sheet metal cutter

Visit our Press Presss Accesories Product Category.

a

Additional Insights:

- The PROFI PUNCH ‘10 performs the punching process through plastic deformation of material by the dynamic impact of the punch. It’s designed to punch holes and make undercuts in sheets and sections. Depending on the material type, it can punch sheets with a maximum thickness of 4mm, including ordinary steel, acid-resistant steel, and aluminum.

- For larger sheets, special tables with adjustable height are recommended, though they aren’t part of the standard equipment.

For those in workshops, factories, and industrial settings, the RHTC Profi Punch 10 is more than just a punching machine for sheet metal; it’s a testament to engineering excellence and operational efficiency. If you’re in the market for a punching machine with automatic mode, adjustable piston stroke, and CE certification, look no further.

*** IN THE PRODUCT GALLERY ARE DISPLAYED OPTIONAL TOOLS FOR THE PP-10 MACHINE. THESE ARE NOT INCLUDED. ***