Frequently Asked Questions about Deep Drawing Presses

Q: Why should you choose The Workshop Press Company UK for your deep drawing press needs?

A: Reasons to Choose Us

- We have a wide range of presses to choose from, so you can find the perfect press for your application.

- We offer a range of tooling and accessories to help you get the most out of your deep drawing press.

- We have a team of experienced technicians and engineers who can help you choose the right press for your needs and train you on how to use it.

- We offer factory to factory, front to back service from the time you order a press.

- We offer competitive prices and excellent customer service.

Q: What is deep drawing?

A: Deep Drawing Process

Deep drawing is a metal forming process in which a flat metal sheet is drawn into a forming die by the mechanical action of a punch. The process is considered “deep” drawing when the depth of the drawn part exceeds its thickness.

Q: What are the benefits of deep drawing?

A: Benefits of Deep Drawing

Deep drawing is a versatile process that can be used to create a wide variety of parts, including cups, bowls, tubes, and other hollow objects. It is an efficient process, which can save time and money by increasing efficiency and reducing your scrap rate.

Q: What are the limitations of deep drawing?

A: Limitations of Deep Drawing

The main limitation of deep drawing is that it can be difficult to control the thickness of the drawn part. This can lead to problems such as wrinkles, thinning, and tearing.

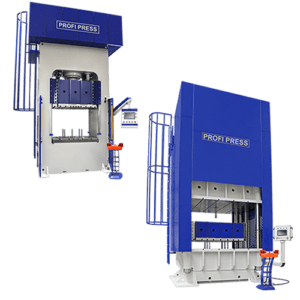

Q: What are the different types of deep drawing presses?

A: Types of Deep Drawing Presses

There are two main types of deep drawing presses: hydraulic presses and mechanical presses. Hydraulic presses are the most common type of deep drawing press. They are powered by a hydraulic cylinder, which provides a smooth, controlled force. Mechanical presses are less common.

Q: What factors should I consider when choosing a deep drawing press?

A: Key Considerations

- The size and complexity of the parts you will be producing

- The volume of production you need

- Your budget

- Available space

- In-house technical manufacturing capabilities

Q: What are the common problems in deep drawing?

A: Common Problems

- Wrinkles: can occur if the blank is not properly prepared or if the pressure is applied too quickly.

- Thinning: can occur if the blank is not supported properly or if too much pressure is applied.

- Tearing: can occur if the blank is of the incorrect material, either too soft or too strong, or if too much pressure for the relative application is used.

- Fractures: are cracks that can be caused by a number of factors, including too much pressure being employed, the blank not being of the correct material for the desired application, or the blank not being supported properly.

- Surface Defects: surface defects occur on the drawn part as a result of the deep drawing process and they include scratches, burrs, pitting, and delamination.

Q: How can I avoid deep drawing problems?

A: Avoiding Problems

- Ensure the desired metal is suitable for deep drawing.

- Choose a deep drawing press with the proper framework and capacity for your deep draw pressing needs.

- Do not take the cheap route on tooling; ensure it is high quality.

- Follow the correct deep drawing procedures for the metal blank preparation, pressure settings, and die set setup for your application.

If you have any other questions about deep drawing presses, please do not hesitate to contact us. We would be happy to help you find the right press for your needs.

Contact us today to learn more about our deep drawing presses and services.