Frequently Asked Questions about Horizontal Press Brake Presses

Q: What is the maximum pressure capacity of the hydraulic press?

A: Capacity varies by model.

The maximum pressure capacity of a hydraulic press varies depending on the specific model and design. Our standard offering of horizontal hydraulic presses ranges from 10 tons up to 100 tons, catering to different applications and requirements.

Q: What is the maximum stroke length or ram travel distance of a horizontal press brake?

A: It refers to the maximum piston travel.

The maximum stroke length or ram travel distance refers to the maximum distance the piston can travel during operation. This horizontal range of motion is a crucial factor when selecting a hydraulic press for your specific application.

Q: What is the working table width or bed size of the press and how does this relate to usable working space?

A: Table width determines usable space.

The working table width or bed size determines the horizontal distance available for the workpiece. Usable working space varies by press size and design, defined as the maximum space from left to right and up to the piston face of the horizontal press.

Q: What materials can the press handle? Is it suitable for specific materials such as metal sheets, plates, or tubes?

A: Suitable for a wide range of materials.

Hydraulic presses can handle various materials, including metals, plastics, and composites. They are commonly used for metalworking with materials such as steel, aluminum, copper, and stainless steel. Specialized tooling allows for processing metal sheets, plates, and tubes.

Q: Can the press accommodate various tooling or dies for different applications?

A: Yes, it is versatile.

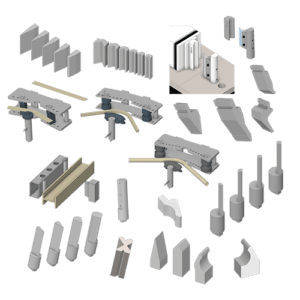

Hydraulic presses are designed to accommodate a wide variety of tooling or dies, making them versatile for different tasks. They feature removable or interchangeable tooling, including a Mounting Face Plate, V-Punch Tool, V-Die Tool, and Mounting Pins. Bespoke tooling is also available.

Q: What is the speed of the press, both in terms of approach and return stroke and is it adjustable?

A: Speed is adjustable.

The speed of a hydraulic press is adjustable and controlled by a valve system. The maximum speed is 11 mm per second, and the controls vary depending on the specific model and design.

Q: What safety features are incorporated into the machine? Are emergency stops and overload protection included?

A: Multiple safety features included.

Our horizontal press brakes are equipped with various safety features, including:

- Emergency Stops: Easily accessible emergency stop buttons allow operators to quickly halt the machine’s operation in case of an emergency.

- Overload Protection: Overload protection systems prevent damage from excessive force or pressure, including pressure relief valves or sensors that automatically limit the pressure within safe parameters.

Q: Is the press customizable or available in different configurations to suit specific requirements?

A: Custom configurations are available.

Yes, custom and bespoke configurations are available to suit specific customer needs. Please talk to our knowledgeable sales staff to discuss your requirements.

Q: What is the power source required for operating the press (electricity, hydraulic power unit)?

A: Standard and custom power options.

The standard horizontal workshop presses come in 400V, 50 Hz, 3-Phase power, but 1-Phase systems and 120V systems are also available.

Q: How user-friendly is the control system? Does it have a user interface for easy operation and parameter adjustment?

A: User-friendly controls available.

Two standard control systems are offered: a basic DRO for inputting stroke length and return position, and a touchscreen HMI for programming a variety of bends in sequence.

Q: Can the press be integrated into an automated production line or synchronized with other machinery?

A: Integration is possible.

Yes, we can provide controls that allow our horizontal press brakes to be integrated into manufacturing systems.

Q: What are the maintenance requirements and recommended service intervals for the press?

A: Regular maintenance ensures longevity.

Maintenance includes daily testing of safety features, cleaning the machine and tables, and checking hydraulic fluid levels. Some companies flush and replace hydraulic oil annually, while others check and top up as needed. Service schedules and packages are available upon request.

Q: Does the manufacturer provide warranty coverage and after-sales support?

A: Warranty and support included.

The Workshop Press Company offers a 2-year manufacturer’s warranty on its horizontal press brakes. Service contracts and ad hoc service calls are available, and our service staff is always ready to assist.

Q: Are there any additional optional features or accessories available for the press?

A: Various optional features available.

Optional features include:

- Bespoke tools

- Custom control systems

- Automated stop system controlled with a touchscreen HMI

- Custom tool holding pins

- Extended manual side stop systems

- Palm button control

- Custom safety features and controls

- Bespoke table sizes