Broaching Hydraulic Presses

Are you looking for A Broaching Press For Sale? Workshop Press is a leading provider of high-quality metal fabrication equipment in the United Kingdom. This includes Broaching Hydraulic Press Machines. Broaching has been practised since the early 1850s. It’s frequently in use for creating one-of-a-kind parts. It may, however, be in use for high-volume metal-removal procedures.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

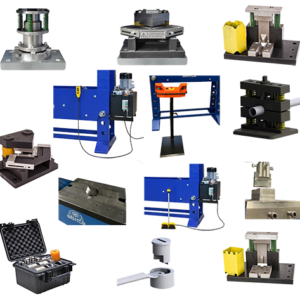

Global ShippingWelcome to our broaching presses product page, where we introduce hydraulic broaching presses—an essential machine tool for creating precise and dimensionally accurate holes, slots, and other metal features. These versatile machines find applications in a wide variety of industries, including manufacturing dies and molds, producing precision parts for aerospace, automotive, and medical sectors, as well as repairing and reworking existing parts.

Hydraulic broaching presses utilize a hydraulic cylinder to exert force on a broach which is a hardened tool with a series of cutting teeth. By feeding the broach into the workpiece, the hydraulic cylinder drives the teeth to progressively remove material until the desired profile is achieved.

One of the main advantages of hydraulic broaching presses is their ability to produce highly accurate parts with consistent repeatability. Additionally, these presses are relatively user-friendly, making them an ideal choice for metal fabricators requiring regular production of precision parts.

Some technical details about hydraulic broaching presses:

- Hydraulic cylinder force: The force applied by the hydraulic cylinder is typically measured in tons, allowing for precise control over the cutting process.

- Broach size: The size of the broach is determined by the desired diameter and depth of the hole or slot being cut.

- Advance speed: The advance speed can be adjusted using a variable-speed drive, enabling customization based on specific requirements and materials.

If you are a metal fabricator seeking a reliable and precise machine tool for producing high-quality precision parts, a hydraulic broaching press from The Workshop Perss Company is an excellent choice to consider. Its accuracy, repeatability, and ease of operation make it an invaluable asset for your manufacturing processes.