Frequently Asked Questions (FAQs) about Drill Presses

Q: What is a Pillar Drill Press?

A: Introduction to Pillar Drill Presses

A Pillar Drill Press is a machine tool that has a motor driving a rotating drill bit to make holes in a variety of materials. It is a versatile metal fabrication machine tool that can be used for a wide variety of tasks, including drilling holes in wood, metal, plastic, and other materials.

Q: What are the different types of drill presses?

A: There are two main types of drill presses:

Benchtop and floor-standing. Benchtop drill presses are the smallest and most portable type of drill press. They are typically used for light-duty tasks, such as drilling holes in wood or plastic. Floor-standing drill presses are larger and more powerful than benchtop drill presses. They are typically used for heavy-duty tasks, such as drilling holes in metal.

View our complete Pillar Drill Offering by clicking HERE.

Q: What are the benefits of using a pillar drill?

A: There are many benefits to using a drill press, including:

- Accuracy: Used to drill holes with a high degree of accuracy.

- Speed: Drill holes quickly and easily.

- Versatility: Can be used for a variety of tasks.

- Durability: Quality materials, components, and craftsmanship means our Pillar Drills are built to last.

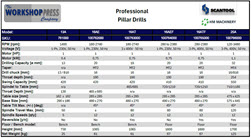

Q: What options are available for a pillar drill press?

A: There are many options available for Pillar Drill Presses:

- Floor / Bench: Options available for both floor and bench models.

- Drilling Feed: Manual or automatic drilling feed options.

- Tapping Feed: Manual or automatic tapping feed options.

- Drive: Drive systems include V-Belt, Gear, or Direct options.

- Table: Fixed or variable rotating table configurations.

- Headstock: Rotating headstock available.

- Weight (Kg): Weight varies depending on model and configuration.

- Lighting: Equipped with lighting for improved visibility.

- Coolant: Some models feature coolant systems for tool lubrication and cooling.

- Drilling (Ø mm): Drilling capacity ranges provided in diameter (Ø mm).

- Tapping: Tapping capacity specified for each model.

- Speeds: Variable speed control or preset speed options available.

- Motor (kW): Motor power output listed in kilowatts (kW).

- Taper: Taper options include MT3, MT4, or MT5.

Q: What is the difference between an industrial and professional pillar drill?

A: Differentiating between an Industrial and a Professional Pillar Drill Press:

When differentiating between an industrial and a professional pillar drill, it’s important to consider their intended use, construction, and capabilities. Industrial pillar drills are designed for continuous, heavy-duty applications in demanding environments such as metal fabrication shops and manufacturing plants. They feature powerful motors, advanced gear-driven mechanisms, and enhanced durability to handle larger drill bits and tougher materials with precision and reliability. In contrast, professional pillar drills are built for non-production use, offering robust construction and user-friendly features suitable for workshops, small businesses, and educational institutions. These drills provide reliable and precise performance for regular tasks in various fields, ensuring accuracy and control for detailed work.

Q: There are so many different drills that you offer, how do I choose the right one for my needs?

A: Key considerations for choosing the right pillar drill:

Several factors are critical to consider, including the type of materials you’ll be working with, the size of the drill bits, and the frequency of use.

- Drilling and Tapping Capacity: Ensure the drill press can handle the required sizes of holes you need to drill and tap. Industrial models typically offer larger capacities and can handle tougher materials.

- Auto Feeds: For increased efficiency, look for models with auto-feed capabilities for both drilling and tapping.

- Table Sizes: Consider the size of the worktable and whether it can accommodate the workpieces you plan to drill.

- Speed Settings: Multiple speed settings or variable speed control can help you adapt the machine to different materials and drilling conditions.

- Additional Features: Look for features such as coolant systems, safety mechanisms, and adjustable tables for enhanced functionality and safety.

To assist in your decision-making process, refer to the capacity charts provided below, which detail the capabilities of different drills. Additionally, you can contact the professional and experienced staff at The Workshop Press Company UK for personalized assistance. They are available by phone, contact forms, or email to help you select the drill that best fits your requirements.

To further assist in your decision-making process links to the respective product categories are provided:

Q: What are the safety precautions to take when using a drill press?

A: There are a number of safety precautions to take when using a drill press, including:

- Always use the appropriate PPE, especially safety glasses, when using a drill press.

- Ensure the workpiece is secure before drilling.

- Use the correct drill bit for the material you are drilling. For example, do not use a wood drill bit for drilling holes in metal.

- Do not overload the drill press, as it creates a dangerous working environment.

- Turn off the pillar drill press and isolate the power supply before changing bits or removing the workpiece.

By following these safety precautions, you can help to prevent injuries and ensure a safe working environment when using a drill press.

Q: What is a Drill Tap and what is it used for?

A: A drill tap is a tool used to create threads in a hole.

A drill tap is typically made of hardened steel and has two cutting edges that spiral inward. The drill tap is inserted into the hole and rotated by hand or with a power tool, cutting threads in the hole. Drill taps come in a variety of sizes and pitches, determined by the diameter of the hole and the number of threads per inch required.

Here are some tips for using drill taps:

- Use the correct type of drill tap for the material you are working with. As with drill bits, never use a tap on a material it is not designed for.

- Use cutting oil to lubricate the drill tap and help it cut through the material.

- Do not force the drill tap. Apply only light pressure and let the tool do its work.

- Continue tapping until the tap reaches the desired depth; do not stop midway.

By following these tips, you can use drill taps safely and effectively, creating clean and accurate results.

Q: What is an Auto-Tapping Feature on a Pillar Drill?

A: Auto-tapping is a feature present only on certain Pillar Drill Presses:

This feature allows the operator to tap pre-drilled holes to allow for the insertion of screws without having to do it manually. It saves time, effort, and money, and helps achieve more accurate results.

Benefits of using an Auto-Tapping feature on a Pillar Drill:

- Saves time and effort.

- Helps to get more accurate results.

- Simplifies the tapping process making it easy to use.

If you are looking for a way to save time and effort when tapping holes, then auto-tapping is a great option. It is a simple and effective way to get more accurate results. Keep in mind that not all pillar drill machines have the auto-tapping feature, so make sure to do your research or contact our sales team, and they will help you find the correct drill to suit your tapping needs.

Q: What does an Auto-Feed Feature do on a Pillar Drill?

A: An auto-feed feature on a drill press is a mechanism that automatically feeds the drill bit:

The drill bit is fed into the workpiece at a controlled and consistent advance rate, helpful for drilling accurate holes efficiently.

Benefits of using an auto-feed feature on a drill press:

- Accuracy: Auto-feed features help drill holes more accurately.

- Speed: Auto-feed features help drill holes more quickly.

- Safety: Auto-feed features prevent accidents by consistently and automatically feeding the drill bit into the workpiece.

If you are looking for a way to drill holes more accurately, quickly, and safely, then you should consider using a drill press with an auto-feed feature.

Q: How is the Speed or the RPMs of a Pillar Drill Controlled?

A: There are several ways to control the speed of a drill press:

- Variable speed: Variable speed drill presses have a dial or knob to adjust the speed. Some models have infinitely adjustable speed with a corresponding digital readout.

- Belt-driven: Belt-driven drill presses have a belt that connects the motor to the drill spindle, controlled by adjusting the belt onto various pulleys.

- Gears: Some drill presses have gears that operate like a transmission, with various gear combinations chosen through turning knobs on the casing.

Tips for choosing the right speed for your drill press:

- The type of material you are drilling: Use a slower speed for drilling metal than for drilling wood.

- The size and type of the drill bit: Use a slower speed for drilling a large hole than for drilling a small hole.

- The depth of the hole: Use a slower speed for drilling a deep hole than for drilling a shallow hole.

By following these tips, you can choose the right speed for your drill press and avoid damaging the drill bit or the workpiece.

Q: What is a Machine Taper and what type of taper do pillar drills have?

A: Pillar Drill presses typically have a Morse Taper:

- Morse tapers: Morse tapers are self-locking tapers used to secure drill chucks and other tooling in the spindle of a machine tool. They come in eight sizes, identified by whole numbers between 0 and 7, with MT2 or MT3 being the most common in drill presses up to 13 mm capacity.

- Jacobs tapers: Jacobs tapers are similar to Morse tapers but with a different taper angle. They come in seven sizes, identified by whole numbers between 0 and 6, with #3 being the most common in drill presses.

The type of machine taper that a drill press has depends on the manufacturer and model. If you are not sure what type of machine taper your drill press has, you can consult the owner’s manual or talk to our knowledgeable sales staff.

Q: What are the Advantages of using a Pillar Drill for Metal?

A: Advantages of using a pillar drill include:

- Accuracy: Capable of drilling holes with high precision.

- Speed: Able to drill holes quickly and efficiently.

- Versatility: Suitable for a wide range of tasks and materials (wood, metal, plastic).

- Durability: Our pillar drill machines are built with quality materials and craftsmanship for long-lasting performance.

- Options: Various configurations and features available such as auto-feed, lighting, coolant systems, variable speeds, and different drive systems.

- Industrial vs. Professional Use: Our broad offering has models that are tailored for heavy-duty industrial use or more moderate professional tasks.

- Consistency: Provides consistent results for repetitive tasks.

- Ease of Use: User-friendly controls and adjustable settings.

- Enhanced Safety: Equipped with safety features to protect users during operation.

- Support and Accessories: Wide availability of accessories and support for customization.

If you are unsure about how the advantages of a pillar drill can benefit your facility, please contact our professional and experienced staff for advice and assistance.

Q: What are the disadvantages of using a Industrial Pillar Drill?

A: Disadvantages of using a pillar drill include:

- Size and Space Requirements: Floor-standing models require a good amount of space and may complicated floor space issues for small workshops.

- Complexity: Advanced models with multiple features (e.g., auto-feed, variable speed, auto-tapping) for inexperienced users will having a learning curve.

- Learning Curve: Some users may need training to effectively operate advanced models.

- Cost: High-quality, durable models with numerous features can be more costly than the less expensive and popular models seen in common web searches.

- Power Consumption: More powerful models may consume more energy, which could increase operational costs.

- Manual Handling: Some tasks might still require manual handling and adjustments, especially with basic models.

- Setup Time: Initial setup and adjustments can be time-consuming and once again have a learning curve before efficiency is experienced.

- Limited Portability: Heavier and larger models are not easily portable.

- Maintenance Requirements: Regular maintenance will be required to keep the machine in optimal condition.

If you have any concerns about the disadvantages of using a pillar drill in your facility, please reach out to our professional and experienced staff for personalised advice and assistance.