Punch Presses

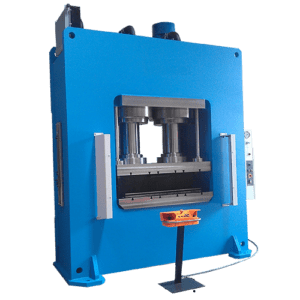

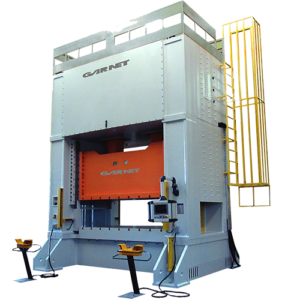

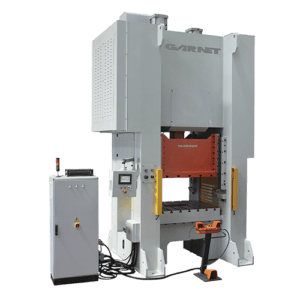

Punch Press or a Punching Press is metal fabrication machine which changes the shape of sheet metal through force. These terms are used for a wide variety of presses with this function. Furthermore, they change the shape of a piece of sheet metal by exerting force through either a hydraulic or mechanical mechanism. Are you looking for a Punching Press Manufacturer? Check out our range below.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global ShippingThe Ultimate Guide to Hydraulic Punch Press Machines for Metal

Hydraulic Punch Presses are an industrial machine that is a versatile tool used for a variety of metalworking tasks such as cutting, shearing, perforating, and forming metal. Punch presses come in a variety of tonnages, designs, and configurations, so it is important to choose the right one for your needs.

The information below describes the different types of punch presses, their features, and how to choose the right one for your needs, and we provide some tips on how to use punch presses safely and effectively.

Types of Punch Presses:

There are two main types of punch presses: Mechanical and Hydraulic. Mechanical punch presses are powered by a motor, while hydraulic punch presses are powered by a hydraulic cylinder. In most cases Mechanical Punch Presses are less expensive than Hydraulic Punch Presses, but they are also less powerful. A Hydraulic Punch Press is generally more powerful than mechanical punch presses, but they are also more expensive.

Features of Punch Presses:

Punch presses come with a variety of features, including:

- Stroke length: The stroke length is the distance that the manufacturing press’s slide table travels in one direction.

- Stroke Control: The stroke control can be mechanically controlled, controlled with micro-switches, or with an HMI (Human Machine Interface).

- Force or Tonnage: The press tonnage or force is the amount of pressure that the punch press can exert.

- Speed: The speed is the rate at which the punch press moves the slide table or piston forward in the stroke or how fast it returns the slide table after the stroke is complete.

- Safety Controls: Punch Presses can have a variety of safety features. Some of the more standard features are light curtains or safety caging that is made of metal of Perspex. E-Stops and Hand Buttons can also be integrated into the press’s safety system.

Choosing the Right Punch Press:

When choosing a punch press, it is important to consider the following factors:

- The type of metalworking tasks that you will be typically using the punch press for.

- The size of the metalworking pieces that you will be working with.

- The type can thickness of material you will typically be working with.

- The amount of force, based on the material to be used and the design of your press piece, that you need the punch press to exert.

- The speed at which you need the punch press to operate, or how many units per minute or hour you need to produce.

Using Punch Presses Safely:

When using punch presses, it is important to always follow these safety precautions:

- Always wear safety glasses when operating a punch press.

- Always wear safety shoes when operating a punch press.

- Never operate a punch press if it is damaged.

- Regularly inspect the press and its controls for damage and impeded functions.

- Check the safety controls before each use.

- Use the correct size tools, punches and dies for the job at hand.

- Operate the punch press at the correct speed and using the correct stroke.

Conclusion:

Punch presses are a versatile tool often found in manufacturing facilities and are used for a variety of metalworking tasks. They come in a variety of sizes and styles, so it is important to choose the right one for your needs. When using punch presses, it is important to follow safety precautions to avoid injury. If you have questions or need assistance in choosing the correct Punch Press for your requirements contact the professional staff at The Workshop Press Company UK on 0800 999 1090 or info@workshoppress.co.uk.