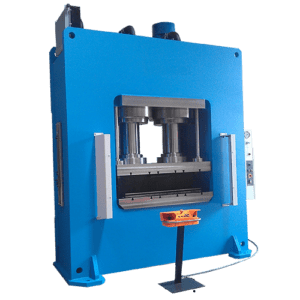

Production Hydraulic Presses

The Profi Press Hydraulic Production Presses are offered in a variety of tonnages, various sized vertical and front openings. There are also various sized slide and bolster tables.

RHTC manufactures Production Presses from S355JR steel. This then creates an electro welded structure, providing a lifetime of service. The lower bolster table and upper slide table come with industry-standard T-grooves. The top slide remains perfectly parallel by using four cylindrical lateral guides. This helps to ensure perfect alignment of the upper table.

Furthermore, the position of this upper table is easy to adjust and control from a side panel.

All production presses have a two-speeds. All Presses are also manufactured in the EU and CE Certified.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global ShippingOur hydraulic production press is made in Europe. Perfect for metal forming and can be easily incorporated into automated production lines. These high-quality production presses have a base hydraulic press framework made from electro-welded S355JR steel. All Production Presses from The Workshop Press Company are equipped with a mechanized lower bolster, and an upper slide table with DIN-650 T-grooves. Workshop Production Presses are based on double acting cylinder with chromed plungers and anti-turning system that has four cylindrical lateral guides are designed to always ensure perfect alignment of the upper table. The stroke of the main upper hydraulic press cylinder is easily controlled and adjusted with an easy-to-use micro-switch system mounted on a side panel.

The PPRM Series Production Presses has a rigid hydraulic system driven by a two-speed motorised hydraulic unit with automatic high speed deactivation, and is equipped with a cylinder decompression valve. Applied tonnage is easily adjusted with an easy access adjustment valve and can be easily viewed on an incorporated manometer that reads in tons.

The PPRM Series Hydraulically Driven Production Presses three operation modes that include manual, semi-automatic and automatic operation modes along with a selector for the two different cylinder speeds: fast operational speed and a slow maintenance speed. Standard Safety Features include level IV photo-electrical sensors mounted at the front of the press. Access for setup and changeover is through two rear protection panels than can be opened but are protected with a micro-switch disconnection system. The PPRM series hydraulic presses are designed and manufactured in the EU and have electric and hydraulic systems and components that adhere to latest safety CE-regulations. All Production Presses, both standard and bespoke presses, come with a two-year guarantee.

The Production Press series PPRM is suitable for stamping, die-cutting, deep-drawing and forming of sheet metal, and is used in such industries as White Goods, Aerospace, Train, Automobile panels and components, Furniture, Consumer Goods, Munitions and Weaponry, MoD Applications, Forging, and many more.

Our range of Hydraulic Production Presses come in a feature rich package but can be customised to suit the customer’s needs. A variety of bespoke features such as a hydraulic cushions or ejectors, Digital NC-Siemens Controls, or bespoke dimensions to accommodate your needs.

The Standard Technical Specifications for the PPRM Series Production Presses include tonnages form 80 to 500 tons and a top-quality European motor. The working cycle includes three speeds including quick advance approach speed, reduced working speed, and quick-advance return speed. Each press has a piston stroke ranging from 300 to 500 mm depending on the size of the press. On all production presses the lower bolster and upper slide tables are amply proportioned and come with standard DIN-650 T-Slots, and the bolster table working height is from 750 to 1000 mm contingent on the model. In addition to the main cylinder piston there are four guides which range from 50 mm to 80 mm depending on the chosen model. All presses in the standard offering vary dimensionally, so please view each press to view its dimensions.

Some common options include a SIEMENS SIMATIC S7 1200 KTP-700 with 7 inch touch screen, accelerated approach and return speeds facilitated by a valve prefilling system, hydraulic cushions and ejectors placed in the upper or lower tables, or in both tables, and cooling or heating equipment for the hydraulic system.