Frequently Asked Questions about Motorised Workshop Presses

Q: What is the difference between a Motorised Workshop Press and a Manual Workshop Press?

A: Differences in Power and Usage

The main difference between a Motorised Workshop Press and a Manual Workshop Press is how the hydraulic cylinder is powered. A motorised workshop press is powered by a hydraulic power pack and pump driven by an electric motor, while a manual workshop press is powered by a cylinder that uses a lever to introduce pressure into the cylinder thus moving the piston rod. Motorised workshop presses are more powerful, easier to use, and more efficient than manual workshop presses, and due to their ease of use, they are used for a wider variety of tasks.

Manual workshop presses are less expensive than motorised workshop presses and are most often, and they can be a good option for users who do not need the extra power or ease of use of a motorised press. However, they can be more difficult to use, and they require the user to exert more physical force.

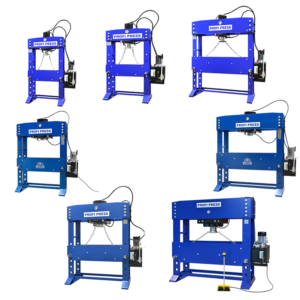

Q: What are the different types of Motorised Workshop Presses?

A: Types of Motorised Workshop Presses

- Benchtop presses: Benchtop presses are small and sometimes portable presses that are designed to be used on a workbench surface. Due to their size, they are less powerful than floor-standing presses, but they are also more affordable and easier to move.

- Floor-standing presses: Floor-standing presses are larger and more powerful than benchtop presses and are placed and mounted to the floor. Floor-standing presses are ideal for heavy-duty tasks such as metalworking and fabrication applications.

Subcategories Based on Power Source:

- Motorised Hydraulic presses: Motorised Hydraulic Presses use an electric motor and hydraulic pump to move fluid into a cylinder to generate force. They are typically the most powerful type of workshop press and are often used for industrial applications.

- Manual Hydraulic presses: Hydraulic presses use a hand pump to move hydraulic fluid into the cylinder to generate force. They are typically smaller and have less tonnage than the motorised versions and can be used for industrial applications but are most often used in light applications or hobby work.

- Pneumatic presses: Pneumatic presses use compressed air versus oil to generate force. They are less powerful than hydraulic presses and are less expensive. Pneumatic presses are used for light-duty tasks such as assembly and packaging.

Q: What are the benefits of using a motorised workshop press?

A: Benefits of Motorised Workshop Presses

- Power: Motorised workshop presses are more powerful than manual presses allowing them to be used for a wide variety of tasks.

- Accuracy: Motorised workshop presses are used to more accurately apply force than manual presses, which is important for tasks and applications in the metalworking and fabrication industries.

- Speed: Motorised workshop presses apply force at a much faster rate than manual presses, which saves time and effort increasing the efficiency of the worker.

- Safety: Motorised workshop presses are typically safer to use than manual presses, as they do not require the user to exert as much physical force.

- Versatility: Motorised workshop presses due to their flexibility are used for a wide variety of tasks in the metalworking, woodworking, moulding, automotive repair, motorsport, aerospace, and many other industries.

Q: What are the common safety precautions that should be taken when using a Motorised H-Frame Workshop Press?

A: Safety Precautions

- Always wear safety glasses and other personal protective equipment (PPE) when operating a motorised workshop press. This includes gloves, a hard hat, and closed-toe shoes.

- Never operate a motorised workshop press while under the influence of alcohol or drugs.

- Always keep children and pets away from a motorised workshop press.

- Never operate a motorised workshop press if it is damaged or malfunctioning.

- Always use the proper dies and tooling for the job you are doing.

- Never overload a motorised workshop press.

- Always be aware of your surroundings when operating a motorised workshop press.

- Do not put your hands or other body parts in the path of the press ram.

- Do not operate a motorised workshop press if you are not familiar with its operation.

- Always read the manufacturer’s instructions carefully before operating a motorised workshop press.

Q: How do I choose the right motorised workshop press for my needs?

A: Choosing the Right Press

Choosing the right motorised workshop press for your needs can be a daunting task and takes research and careful consideration of the specifications of the H Frame Press. There are several factors to consider such as what you intend to use the press for on a daily basis, the size of the press, the amount of force it can exert, and the features it offers.

Tips for Choosing the Right Press:

- Consider the size of the press. How much space do you have in your workshop? If you have a small workshop, you will need a smaller press. If you have a large workshop, you can get a larger press.

- Consider the amount of force the press can exert. What is your intended typical use of the press and how much force do you need the press to exert? If you need the press for light-duty tasks, you can get a smaller press or potentially a manual press, but a motorised press is more efficient and easier to use in all situations. If you are going to be using the press for heavy-duty tasks, you will need a press with a higher force rating.

- Consider the features of the press. What features are important to you? Some features to consider include if the head is movable or static, is the working table adjustable, the diameter of the piston, the diameter of the piston rod, the weight of the press, the footprint of the press, the type of safety features, what accessories are included, and the warranty.

- Set a budget. Our Motorised Workshop Presses can range in price from £2,500 to £30,000. Make sure to set a budget that is commensurate with your requirements before you start shopping.

By considering these factors, you can choose the motorised workshop press that is right for you.

If you are looking for a powerful and versatile tool that can help you with a variety of tasks, a motorised workshop press from The Workshop Press Company UK is the perfect choice for you.

Basic Comparison of a Motorised Workshop Press to a Manual Workshop Press:

| Feature | Motorised Workshop Press | Manual Workshop Press |

|---|---|---|

| Power source | Electric motor | Hand |

| Power | More powerful | Less powerful |

| Ease of use | Easier to use | More difficult to use |

| Cost | More expensive | Less expensive |

| Applications | Wide variety of tasks | More limited range of tasks |