Pillar Drill Presses

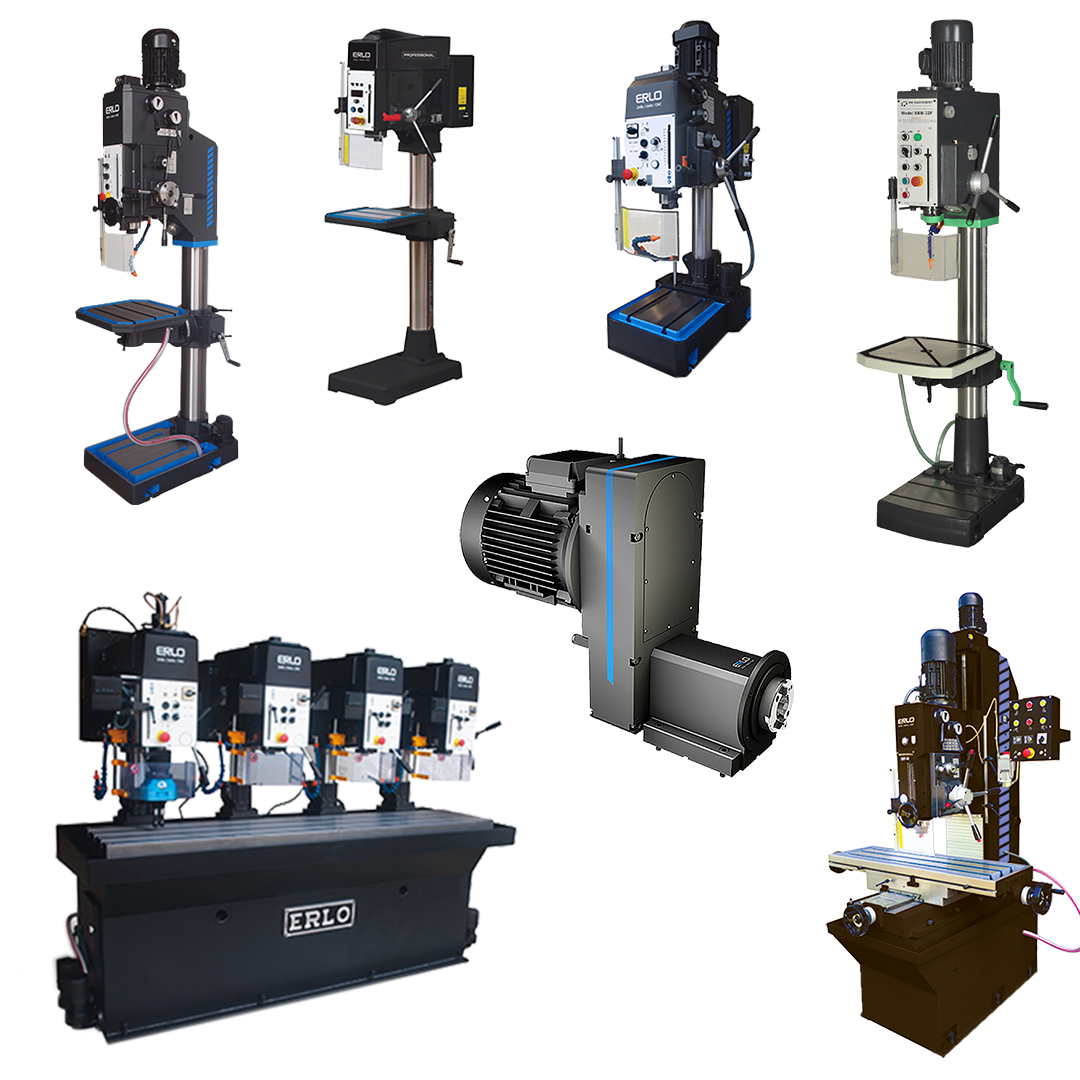

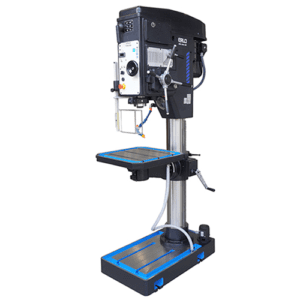

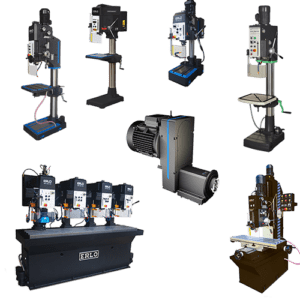

Pillar drill presses from Erlo and HM Scantool cover every need — from light workshop drilling to heavy-duty industrial applications.

Choose between belt-driven and gear-driven machines, with manual, mechanical, or electromagnetic auto feed options.

All models support tapping operations, and many feature auto-reverse for efficient thread cutting.

With variable speed control and drilling capacities up to 70 mm in steel, these machines offer precision, reliability, and flexibility.

Custom multi-head and gang drilling systems from Erlo are also available for high-volume production environments.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global Shipping-

Autofeed Drilling Machines (4)

-

Autofeed Tapping Pillar Drill Press Machines (7)

-

Bench Top Pillar Drills (10)

-

Floor Standing Pillar Drills (22)

-

Gang Drilling Machines | Multi-Spindle Pillar Drills for Production Use (1)

-

Gear Driven Pillar Drills (22)

-

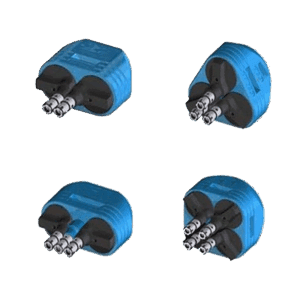

Multi Drill Heads (8)

-

Pillar Drill Presses - In Stock and Special Offers (8)

-

Pillar Drill Presses – 12–16 mm Drilling Capacity – Mild Steel (8)

-

Pillar Drill Presses – 18–25 mm Drilling Capacity – Mild Steel (7)

-

Pillar Drill Presses – 30–35 mm Drilling Capacity – Mild Steel (10)

-

Pillar Drill Presses – 40–50 mm Drilling Capacity – Mild Steel (8)

-

Pillar Drill Presses – 60–70 mm Drilling Capacity – Mild Steel (3)

-

Pulley Driven Pillar Drills (10)

-

Pillar Drills - Industrial (15)

-

Pillar Drills - Professional (7)

-

PIllar Drill and Mill Drill Accessories (37)

-

Mill Drills (4)

Choosing the Right Pillar Drill Press

Selecting a pillar drill press means understanding how drive type, feed system, and speed control affect accuracy, productivity, and tool life. A well-chosen pillar drill ensures reliable performance whether you’re handling light workshop jobs or industrial production runs.

Drive Systems

Erlo and HM Scantool pillar drills are available in two main drive systems:

- V-Belt Drive: Smooth, quiet operation with adjustable pulley ratios. Ideal for general workshop and maintenance tasks.

- Gear Drive: Rigid transmission for high torque and precision. Suited for continuous or heavy-duty use where consistent spindle speed is critical.

Feed Systems & Automation

Most pillar drills are available with manual, mechanical automatic, or electromagnetic automatic feed. Automatic feed helps maintain drilling depth and improves repeatability in repetitive production. Machines equipped with auto-reverse are especially useful for tapping operations, as the spindle retracts automatically when the thread is complete.

Tapping Capability

All Erlo and HM Scantool pillar drills can perform tapping when equipped with the correct reversible motor, tapping attachment, or auto-reverse control. For full automation, Erlo’s SHE and SH tapping series include built-in auto-feed and auto-reverse systems for efficient thread cutting without manual intervention.

Speed Control & Capacities

Both manual and automatic speed adjustment options are available — from variable pulley control to multi-speed gear transmissions. Erlo’s lineup covers drilling capacities from 18 mm up to 70 mm in steel, while Scantool models provide cost-effective options for small to mid-size work.

Brands & Bespoke Solutions

We supply pillar drill presses from ERLO and HM Scantool, covering every price point and functional requirement. Erlo also designs bespoke drilling and tapping systems, including gang drills and multi-spindle heads capable of drilling or tapping multiple holes simultaneously — ideal for high-volume production and precision manufacturing.

Whether you need a compact belt-driven drill press for the workshop or a custom-engineered multi-head tapping system, we deliver solutions that combine precision, durability, and flexibility for modern production environments.