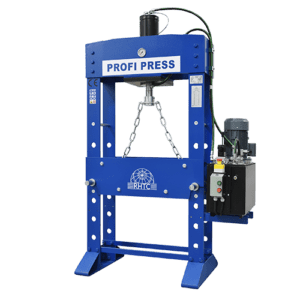

Workshop Press • 50 Ton • Manual Operation • Hand/Foot Pump • Fixed Cylinder • 750 mm Working Width

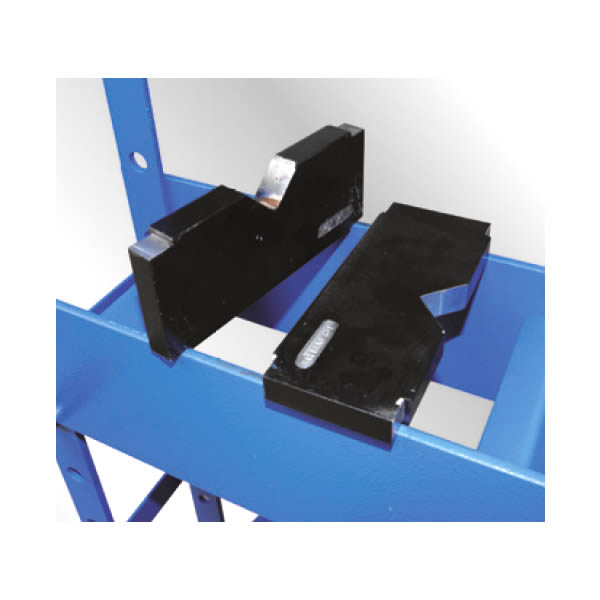

Product Code: PP10011The Profi Press 50-ton manual Workshop Press delivers 490 kN of pressure with its fixed head chrome piston that is 140mm in diameter with a 160 mm stroke. The piston has an auto-return feature that assists with process efficiency. The easy to adjust work table is adjusted with a winch and is constructed of top-grade steel. The table has a working width of 750 mm. This workshop press comes with a set of V-Blocks included.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Moveable Cylinder/li>

- Pressure force [kN]: 490.5

- Pressure max. [bar]: 399.5

- Cylinder stroke [mm]: 160

- System capacity [dm³]: 2.5

- Fixed cylinder: yes

- Working width [mm]: 750

- Weight [kg]: 340

Features

- Hand- and foot operated

- Movable cylinder

- The height of the worktable is easy to adjust by means of a winch

- Integrated pressure manometer

- Chrome piston

- Automatic piston return

- V-block set

- 2 year warranty.

Diameters

- Inside diameter of cylinder [mm]: 140

- Diameter of piston rod [mm]: 50

- Diameter of piston head [mm]: 60

Optional

- Mandrel set of Ø 5, 10, 14, 18, 24 and 29 mm (with a suitable piston head for the 50 ton HF-2)

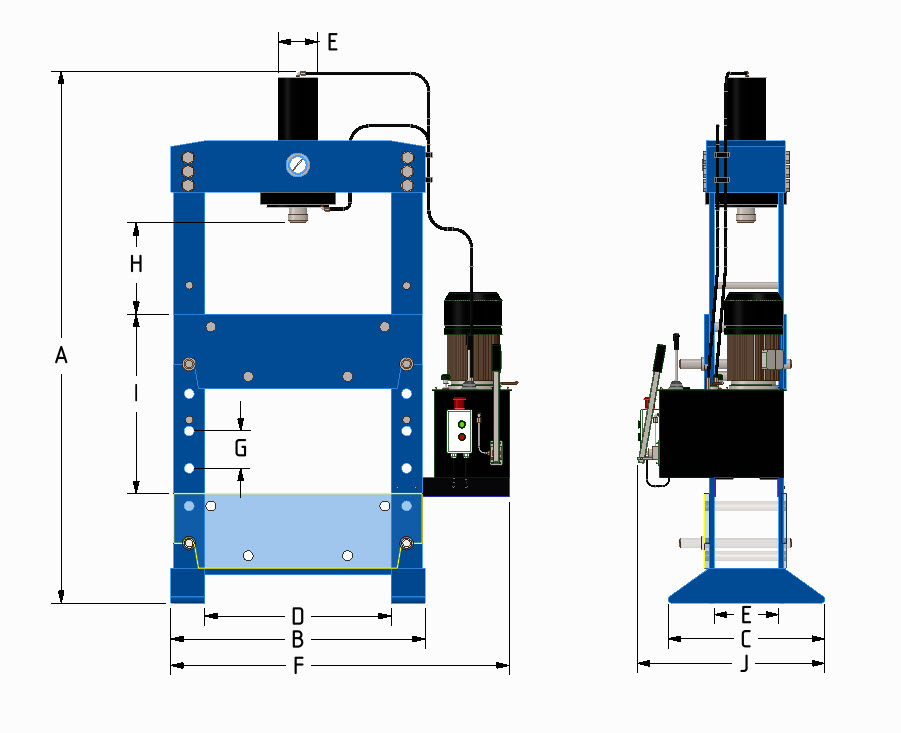

Dimensions

- A: 2025

- B: 910

- C: 764

- D: 750

- E: 300

- F: 1085

- G: 115

- H: 140

- I: 920

- J: 336

- K: 140

Workshop Press

A Hydraulic Workshop Press is a pressing machine that implements hydraulics to compress materials in a variety of applications. Like most shop equipment, hydraulic presses range in quality from basic models but WorkshopPress.co.uk only offers top quality RHTC hydraulic workshop presses. When purchasing an RHTC Hydraulic Press from us it will contribute to your company’s profitability. In addition when a workshop, maintenance, manufacturing or assembly area implements hydraulic workshop press machinery your capabilities are tremendously expanded and you then have the ability to perform a wide variety of different pressing processes and forming processes as well as folding, straightening, forming, riveting, and pressing work. RHTC presses offer usefulness, durability, reliability, functionality, and stability enabling the ability to get more use out of it and more things done efficiently saving you time and most importantly money.

Some Typical Shop Press Uses include: metalwork bending and folding, holding welding projects steady, punching, straightening uneven metal parts, bearing pressing, flattening warped parts, separating rusted parts, compressing, crushing used oil filters to remove excess oil, automobile part construction, jewellery-making, ammunition, and bracket bending.

Profi Motorised Workshop Presses are manufactured in the Netherlands and are CE Certified and are readily available from our stock. This machine has a 1-year warranty.