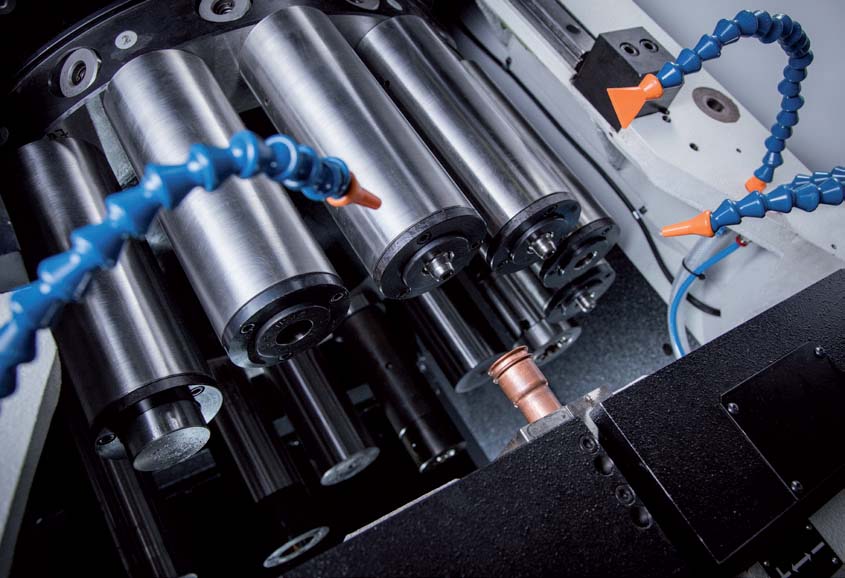

STERN 25 – Compact CNC End-Former for 25mm Tubes

Product Code: Stern 25 End FormerThe PEDRAZZOLI STERN 25 is a compact CNC end-forming machine engineered for precise processing of tube ends up to 25 mm in diameter. Ideal for small-diameter applications, this electric unit delivers high-speed forming, flaring, and threading operations with configurable tool stations and integrated IMS control.

Please contact for prices

- Description

- Additional Info

Designed for tight workspaces and fine tube operations, the STERN 25 End Former is equipped with an electric clamping and forming system, achieving accurate end-shaping results with minimal setup time. It supports up to 8 tools (assumed for size), includes programmable cycles, and is compatible with PEDRAZZOLI’s IMS 4 control system for intuitive operation and remote diagnostics. With reduced energy consumption, quiet operation, and a minimal footprint, the STERN 25 offers industry-grade performance in a compact form factor.

Specifications

- Max Tube Capacity [mm]: 25

- Tool Stations: Up to 8 (assumed)

- Max Thrust [Tons]: 8 (assumed)

- Max End-Forming Length [mm]: 150 (assumed)

- Clamp Force [Tons]: 12 (assumed)

- Installed Power [kW]: 10 (estimated)

- Positioning Accuracy [mm]: ±0.05

- Tool Rotation Speed [RPM]: 2000 (assumed)

- Control System: FANUC CNC + IMS 4

- Footprint [mm]: 1800 x 1000 x 1400 (estimated)

Features

- Electric clamping and forming system

- Compact structure for space-saving installations

- Supports multiple tool functions: flaring, threading, chamfering

- FANUC-controlled IMS 4 interface

- Low maintenance and energy-efficient operation

Options

- Drawplate Holder Sets

- Hydraulic Power Pack for Special Tools

- Remote Service Webcam Kit

- Safety Light Barriers

- IMS Ethernet Network Interface

PEDRAZZOLI, and Italian company established in 1949, manufactures the BEND MASTER Series mandrel tube benders that are designed to meet the most stringent requirements of accuracy, reliability, flexibility, and speed. The control systems are based on the propriety developed Intelligent Motion System, or “IMS” and is run by state-of-the-art industrial computers with touch screens. Software versions allow the user the ability to use a wide variety of standard and bespoke parameters and these options can be customised to suit the customer’s specific requirements.

The Pedrazzoli range of automatic mandrel tube benders implement brushless motors to control the axes surely. The wide variety of available features and accessories ensures an automated bending machine that is very versatile and has the ability to address the most diverse applications and components.

Automation integrations can provide the customer systems with automated loading and unloading systems making the any BEND MASTER tube bender a lights-out workstation.

Easily configurable data ports ensure that the Pedrazzoli mandrel bending machines can be readily integrated into dedicated work cells which can include cutting, punching, end forming, and robotic work stations.

Rapid change tool systems and automated machine adjustments guarantee precision, repeatability, and efficiency when producing bent components. BEND MASTER are designed and are suitable for day-to-day serial or small batch production and Pedrazzoli’s intuitive designs offer reduced cycle times which means cost savings and increased profits.