VH08 Series Multi-Spindle Drill Heads

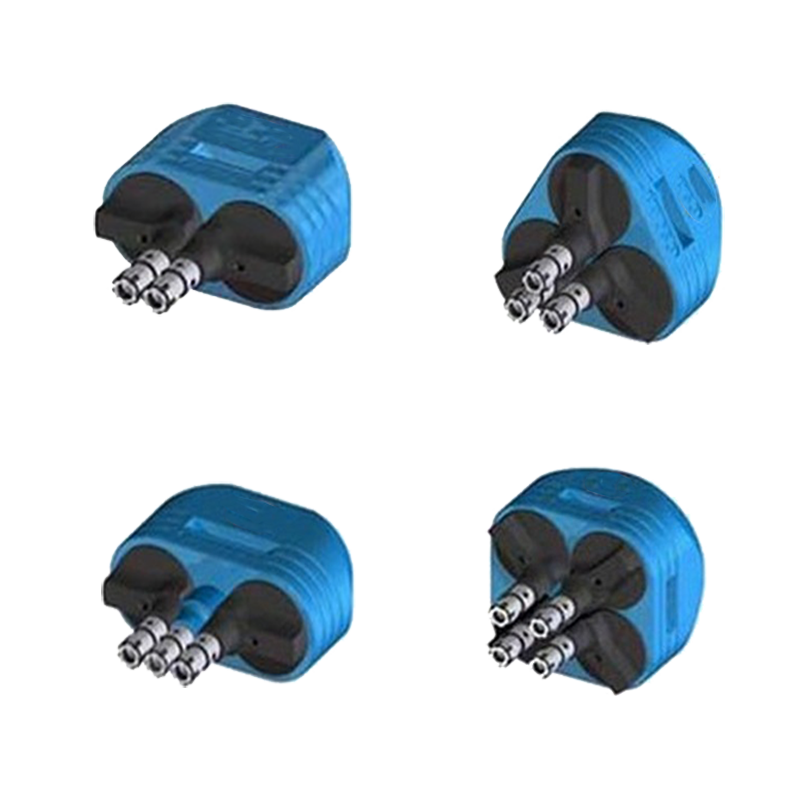

Product Code: VH082 / VH083L / VH083 / VH084The VH08 Series multi-spindle drill heads are designed for high-precision, high-capacity drilling applications in demanding production environments. With ER16 spindles and increased center spacing, the VH08 Series accommodates larger tooling while ensuring synchronized performance. These heads are ideal for radial and linear drilling operations across automatic drilling stations, CNCs, and fixture setups.

Please contact for prices

- Description

- Additional Info

VH08 drill heads offer superior performance for multiple-hole drilling operations where tool size, center-to-center spacing, and mechanical rigidity are critical. Designed for 2, 3, or 4-spindle use, the VH08 Series supports both radial and linear layouts, providing optimal flexibility for production planners.

Capable of drilling up to Ø 10 mm in cast iron and Ø 8 mm in steel, each model features 1:1 synchronized spindle gearing and can operate up to 4,000 RPM. Constructed for continuous-duty cycles, these units integrate seamlessly into drilling stations, feed units, or automation platforms.

VH082 L

VH083 L

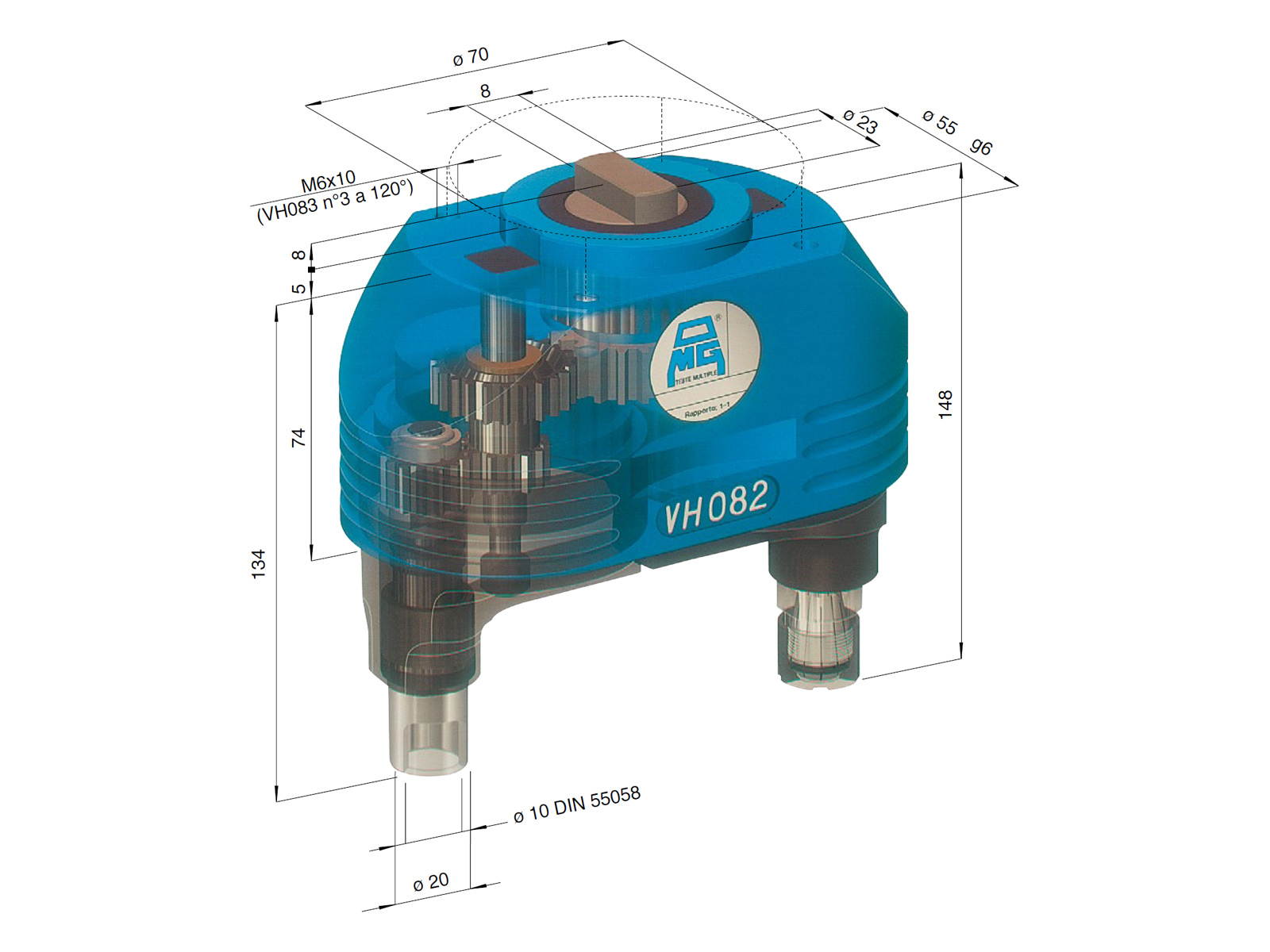

Technical Specifications – VH082

- Item Code: VH082

- Number of Spindles: 2

- Spindle Type: ER16 – max Ø 10 mm

- Center Distance [mm]: 25 + 25

- Max Center Distance [mm]: 160

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 8 mm

- Drilling Capacity (Cast Iron GG25): Ø 10 mm

- Tapping Capacity: M8

- Gear Ratio: 1:1

- Max Speed [RPM]: 4,000

- Weight [kg]: 3.3

Technical Specifications – VH083L

- Item Code: VH083L

- Number of Spindles: 3

- Spindle Type: ER16 – max Ø 10 mm

- Center Distance [mm]: 25 + 25

- Max Center Distance [mm]: 120

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 8 mm

- Drilling Capacity (Cast Iron GG25): Ø 10 mm

- Tapping Capacity: M8

- Gear Ratio: 1:1

- Max Speed [RPM]: 4,000

- Weight [kg]: 4.3

VH083

VH084

Technical Specifications – VH083

- Item Code: VH083

- Number of Spindles: 3

- Spindle Type: ER16 – max Ø 10 mm

- Radial Layout: Ø 29.5 mm spacing

- Max Center Distance [mm]: Ø 123

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 8 mm

- Drilling Capacity (Cast Iron GG25): Ø 10 mm

- Tapping Capacity: M8

- Gear Ratio: 1:1

- Max Speed [RPM]: 4,000

- Weight [kg]: 4.5

Technical Specifications – VH084

- Item Code: VH084

- Number of Spindles: 4

- Spindle Type: ER16 – max Ø 10 mm

- Radial Layout: Ø 41 mm spacing

- Max Center Distance [mm]: Ø 146

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 8 mm

- Drilling Capacity (Cast Iron GG25): Ø 10 mm

- Tapping Capacity: M8

- Gear Ratio: 1:1

- Max Speed [RPM]: 4,000

- Weight [kg]: 5.7

| Model | Spindle Count |

Center Distance (Min-Max) |

Drilling Capacity |

Tapping Capacity |

Max RPM |

Weight |

|---|---|---|---|---|---|---|

| VH 042 | 2 | 12 mm – 72 mm | 4 mm | M3 | 4,000 | 0.95 kg |

| VH 043 L | 3 | 12 mm + 12 mm 42 mm + 42 mm |

4 mm | M3 | 4,000 | 1.05 kg |

| VH 043 | 3 | 0 mm – 785 mm | 4 mm | M3 | 4,000 | 1.4 kg |

| VH 044 | 4 | 0 mm – 895 mm | 4 mm | M3 | 4,000 | 1.9 kg |

| VH 062 | 2 | 17 mm – 93 mm | 6 mm | M5 | 4,000 | 1.65 kg |

| VH 063 L | 3 | 175 mm + 175 mm 555 mm + 555 mm |

6 mm | M5 | 4,000 | 1.95 kg |

| VH 063 | 3 | 0 mm – 103 mm | 6 mm | M5 | 4,000 | 2.3 kg |

| VH 064 | 4 | 0 mm – 117 mm | 6 mm | M5 | 4,000 | 3.1 kg |

| VH 082 | 2 | 24 mm – 108 mm | 8 mm | M6 | 4,000 | 2.2 kg |

| VH 083 L | 3 | 24 mm + 24 mm 66 mm + 66 mm |

8 mm | M6 | 4,000 | 2.9 kg |

| VH 083 | 3 | 0 mm – 120 mm | 8 mm | M6 | 4,000 | 3.4 kg |

| VH 084 | 4 | 0 mm – 137 mm | 8 mm | M6 | 4,000 | 4.6 kg |

| VH 102 | 2 | 28 mm – 120 mm | 10 mm | M8 | 3,500 | 3.5 kg |

| VH 103 L | 3 | 28 mm + 28 mm 74 mm + 74 mm |

10 mm | M8 | 3,500 | 4.9 kg |

| VH 103 | 3 | 0 mm – 132 mm | 10 mm | M8 | 3,500 | 4.9 kg |

| VH 104 | 4 | 0 mm – 152 mm | 10 mm | M8 | 3,500 | 7.2 kg |

| VH 132 | 2 | 35 mm – 151 mm | 13 mm | M10 | 3,000 | 5.3 kg |

| VH 133 L | 3 | 35 mm + 35 mm 93 mm + 93 mm |

13 mm | M10 | 3,000 | 7.2 kg |

| VH 133 | 3 | 0 mm – 167 mm | 13 mm | M10 | 3,000 | 7.7 kg |

| VH 134 | 4 | 0 mm – 191 mm | 13 mm | M10 | 3,000 | 10.8 kg |

| VH 181 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 8.3 kg |

| VH 182 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 10.75 kg |

| VH 183 L | 3 | 41 mm + 41 mm 107 mm + 107 mm |

18 mm | M14 | 2,500 | 12 kg |

| VH 183 | 3 | 0 mm – 191 mm | 18 mm | M14 | 2,500 | 15.75 kg |

| VH 184 | 4 | 0 mm – 218 mm | 18 mm | M14 | 2,500 | 19.75 kg |

| VH 201 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 9.2 kg |

| VH 202 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 12.3 kg |

| VH 203 L | 3 | 45 mm + 45 mm 110 mm + 110 mm |

20 mm | M16 | 2,500 | 13.8 kg |

| VH 203 | 3 | 0 mm – 206 mm | 20 mm | M16 | 2,500 | 17.3 kg |

| VH 204 | 4 | 0 mm – 229 mm | 20 mm | M16 | 2,500 | 21.3 kg |

| VH 251 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 10.7 kg |

| VH 252 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 13.7 kg |

| VH 253 L | 3 | 50 mm + 50 mm 110 mm + 110 mm |

25 mm | M20 | 2,000 | 15.7 kg |

| VH 253 | 3 | 0 mm – 229 mm | 25 mm | M20 | 2,000 | 19.7 kg |

| VH 254 | 4 | 0 mm – 253 mm | 25 mm | M20 | 2,000 | 23.7 kg |

How These Devices Attach to the Drill Press

The VH series heads are designed to be compatible with standard pillar drills using several standardized attachment methods to ensure secure and efficient operation. The attachment mechanisms follow DIN standards, which dictate the type of tooling interfaces that can be used. Below is an explanation of the DIN standards that are applicable and how they affect the attachment of the device to the drill press:

Installation and Setup

The VH series heads are designed for quick and easy installation on standard drill presses.

- Quick Installation: Tooling interfaces like collet chucks and drill sleeves allow for rapid installation of the VH series heads. Operators can swiftly change out heads as needed, enabling different operations without significant delays.

- Easy Setup: Once the appropriate attachment method (sleeve, collet chuck, or steep taper) is selected, aligning and securing the VH series head is straightforward. This ensures repeatability in positioning and operational accuracy.

High-output multi-spindle drill heads with ER16 tool interface, increased spacing, and durable body design for industrial serial production.