Pillar Drill Accessories and Options

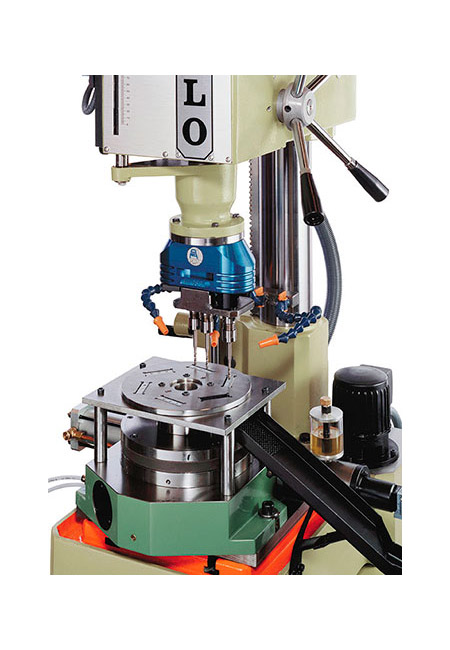

Product Code: Pillar-Drill-Options-AccessoriesOptomise your Drilling Operations: Welcome to our one-stop destination drilling performance and versatility. Dive into our extensive array of accessories and options meticulously curated to cater to every facet of metalworking precision and efficiency. Whether you're seeking robust workholding vices to firmly secure workpieces or high-quality drill chucks for seamless and wobble-free drilling, our collection promises to elevate your workshop's capabilities. Explore our range of coolant pumps designed to keep your drill bits and workpieces cool, ensuring optimal performance and extended tool life. From general-purpose drill bits to specialty options tailored for wood, metal, concrete, and more, we have everything you need to conquer any material with ease. But the offerings don't stop there; delve deeper into our catalog to uncover an extensive selection, including collets, foot pedal controls, taper chucks, tap holders, multi-drill heads, and pneumatic descent controls. Experience the pinnacle of precision and productivity with our premium pillar drill accessories and options, meticulously crafted to meet the demands of modern metalworking workshops.

Please contact for prices

- Description

- Additional Info

Pillar Drill Options and Accessories Category

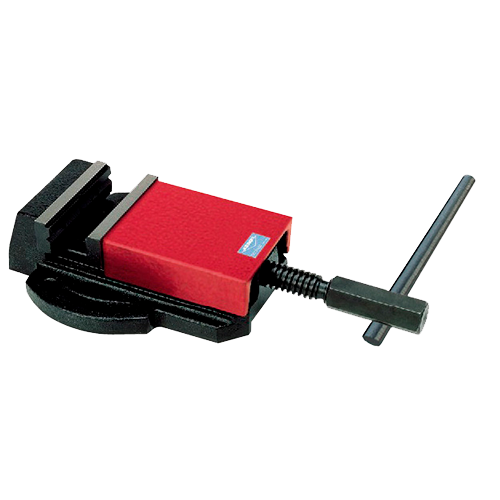

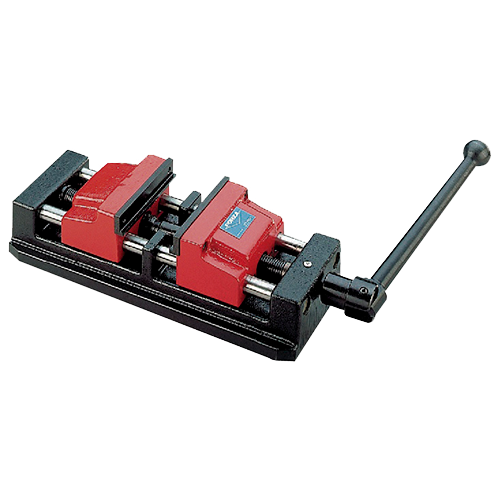

- Workholding Vices: Secure your workpieces with confidence using our selection of heavy-duty vices in various sizes and jaw openings.

- Drill Chucks: Ensure precise and wobble-free drilling with our high-quality chucks, available in a range of types and sizes to suit your needs.

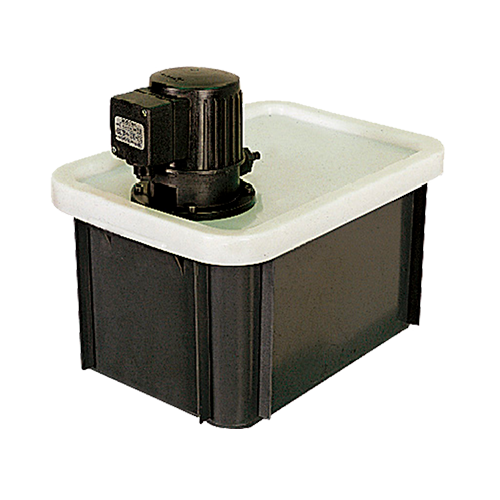

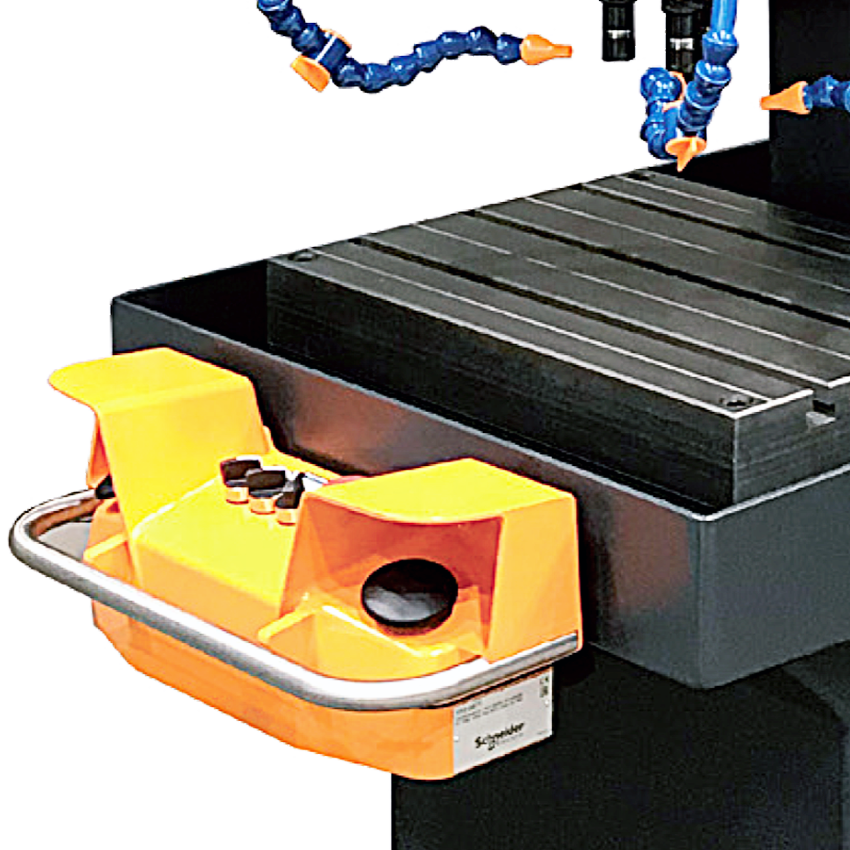

- Coolant Pumps: Keep your drill bits and workpieces cool for optimal performance and extended tool life with our efficient coolant systems.

- Drill Bits: Conquer any material with our diverse range of drill bits, from general-purpose options to specialty bits for wood, metal, concrete, and more.

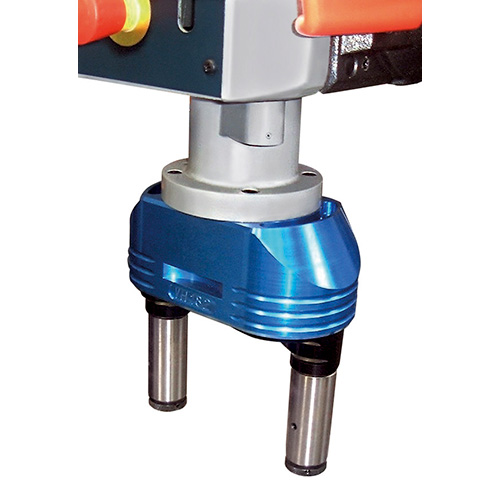

- And Much More! Explore our complete collection, including collets, collett chucks, foot pedal controls, taper chucks, tap holders, multi drill heads, pneumatic descent controls, universal collets, rotating tables, lead screws, machining and drilling vices, and high-speed drill bit sets.

Machine Accessories and Options

- Rapid Approach with Pneumatic Counterweight

- Reduce Feed Range

- Cycles Counter

- Integral Tubes Drilling Cycle

- Motorized Feed for Longitudinal Displacement

- Motorized Feed for Transversal Displacement

- Cooling System

- Lead Screw with Modified Pitch

- Manual Tapping System – Auto-reverse

- Work Light

- Depth Reader – Digital Display (DRO)

- X – Axis Digital Display (DRO)

- X/Y – Axis Digital Display (DRO)

- X/Y/Z – Axis Digital Display (DRO)

- Fixed Vice Base for Tapping

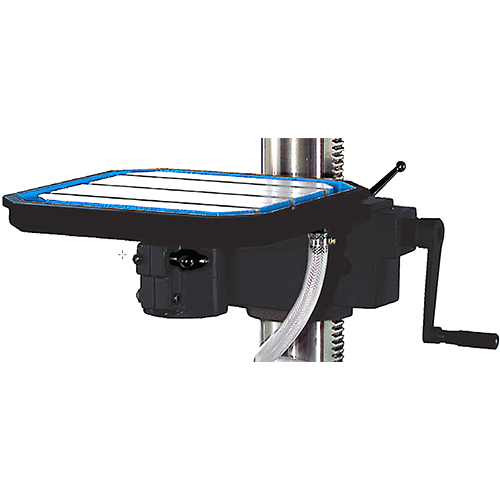

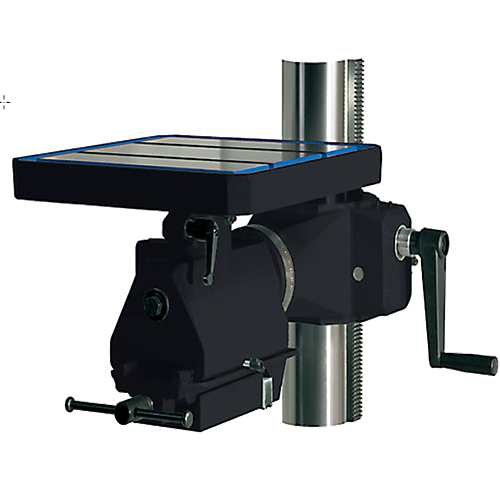

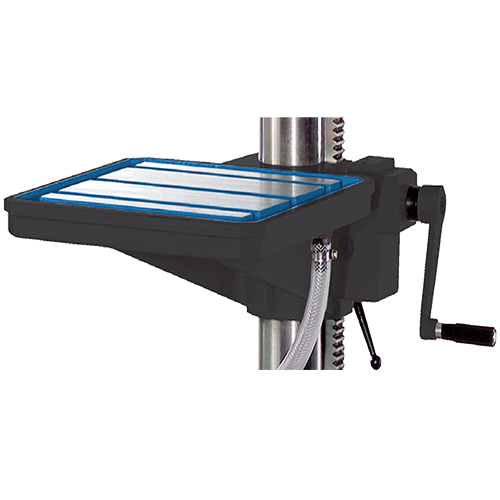

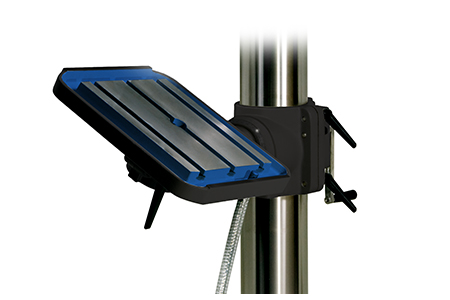

- Work Table – Rotating

- Work Table – Rotating and Tilting

- Work Table – Rotating and Reversible

- Work Table – Fixed Intermediate

- Chuck for 0.5 to 8 mm

- Chuck for 0.5 to 6 mm

- Chuck for 1 to 13 mm

- Base Cabinet with Shelves

- Base Cabinet with Doors and Shelves

- Tap Holders – M4 to M12 – Holds 12 taps

- Collet Holder and a Set of Collets

- Automatic Tapping System

- Column Size – 200 mm

- Column Size – 250 mm

- Feed Advance – Sensitive Feed

- Speed Variator – Electronic

- Speed Display – Electronic – DRO

Machine Accessories and Options

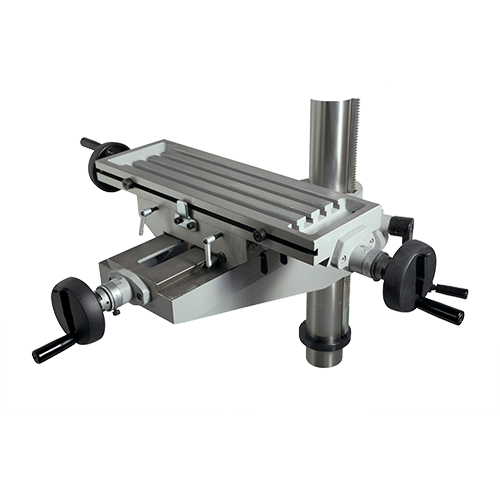

- Work Table – 1000 x 280 mm / Stroke 700 mm

- Work Table – 340 x 190 mm / Stroke 220 mm

- Work Table – 430 x 240 mm / Stroke 180 mm

- Work Table – 600 x 240 mm / Stroke 180 mm

- Work Table – 800 x 280 mm / Stroke 250 mm

- Work Table – Motorized

- Work Table – Large Size – 1118 x 813 mm

- Collet Chuck, Collets, Key, Locking Nut, Storage Box

- Multi-Spindle Cooling System for Spindle

- Auto-Feed for Longitudinal Displacement

- Auto-Feed for Transversal Displacement

- Base for Drill – 520 x 390 mm

- Base for Drill – 600 x 600 mm

- Base for Drill – 800 x 600 mm

- Auto-reverse system for tapping

- Lead Screw with Special Pitch

- Base with an Opening of 116 mm, Jaws 105 mm width

- Base with an Opening of 157 mm, Jaws 125 mm width

- Base with an Opening of 190 mm, Jaws 150 mm width

- Work Table – Motorized

- Rotating Base with an Opening of 116 mm, Jaws 105 mm width

- Rotating Base with an Opening of 157 mm, Jaws 125 mm width

- Rotating Base with an Opening of 190 mm, Jaws 150 mm width

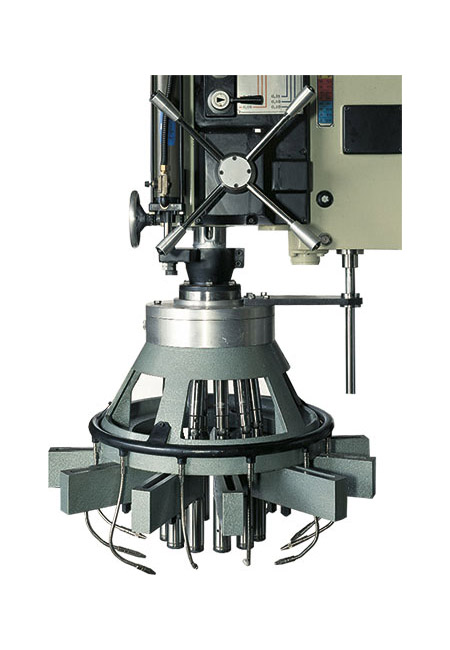

- Multi-Spindle Headstock

- Foot Pedal for Cycle Start

- E-Stop Foot Activated

- Quick Locking Chuck

- Reduction Taper MT2 to MT1

- Reduction Taper MT3 to MT2

- Reduction Taper MT4 to MT3

- Reduction Taper MT5 to MT4

- Reversible Tap HOLDER CAPACITY M.10 TO M.28sb HOLDERCITY M.10

- X/Y Axis DRO

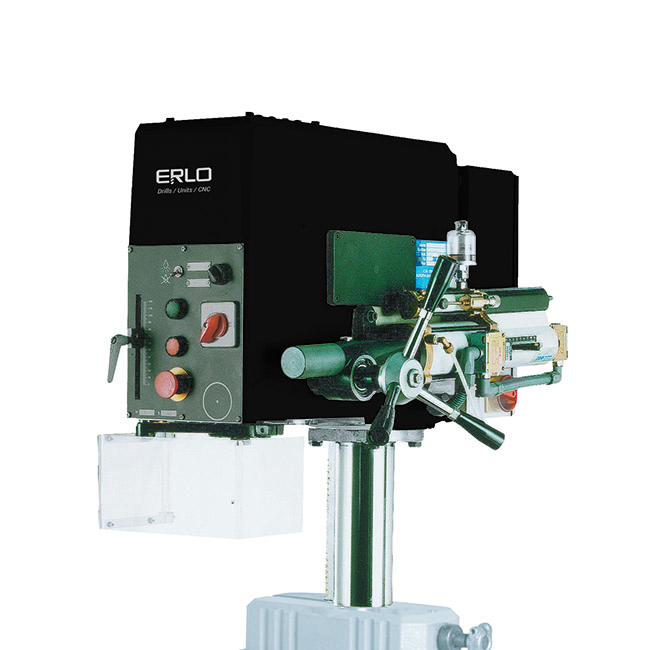

Erlo: Tradition and Innovation in Drilling and Tapping Machines

Erlo is a leading manufacturer of drilling and tapping machines, with over 50 years of experience in the industry. ERLO is known for reliable and durable machines, which are made with high-quality materials and components. ERLO’s machines are also easy to use and maintain, making them a good choice for machinists and metal fabricators of all levels of experience.

In addition to the standard range of drilling and tapping machines, also offered are customized solutions for specific applications are designed with a deep understanding of the custoer’s needs and the machine designs meet those needs perfectly.

It is the belief that tradition and innovation go hand-in-hand and ERLO has a committment to providing their customers with the latest technology and also value the traditional values of craftsmanship and quality.

If you are looking for a reliable and innovative drilling and tapping machine, Erlo is the perfect choice for you. Contact us today to learn more about our products and services.

ERLO products are proudly sold by The Workshop Press Company UK based in Kenilworth, Warwickshire.