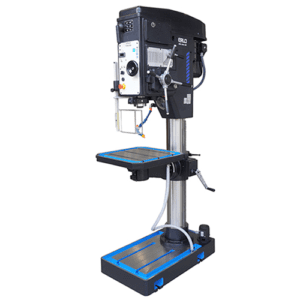

Pillar Drills - Industrial

Our range of Industrial Pillar Drills is engineered to meet the demands of heavy-duty applications in manufacturing and industrial environments. These robust machines are designed for continuous use, ensuring reliability and precision in even the toughest conditions. Featuring powerful motors, advanced gear-driven mechanisms, and versatile speed controls, our industrial pillar drills can handle large drill bits and tough materials with ease. These models are perfect for high-volume production, offering features like auto-feed mechanisms, coolant systems, and enhanced safety features to maximize productivity and operator safety. Suitable for diverse applications from metal fabrication to maintenance workshops, these pillar drills are built to last and perform under pressure.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global ShippingERLO Industrial Pillar Drills Specification Chart

| Series | Capacity | Feed Type | Ideal For |

|---|---|---|---|

| S | Drilling: 18-30 mm Tapping: M14 – M25 |

Drilling: Manual Tapping: Manual |

Basic drilling tasks with manual control |

| SE | Drilling: 25-30 mm Tapping: M22 – M25 |

Drilling: Manual Tapping: Manual |

Precise manual control |

| SEA | Drilling: 25-30 mm Tapping: M22-M25 |

Drilling: Automatic Tapping: Manual |

Automated drilling |

| SH | Drilling: 30 mm Tapping: M14-M25 |

Drilling: Automatic Tapping: Automatic |

Automatic tapping |

| SHE-SHEA | Drilling: 30 mm Tapping: M25 |

Drilling: Automatic Tapping: Automatic |

High-precision tapping |

| FT | Drilling: 8-15 mm Tapping: M5-M8 |

Drilling: Manual Tapping: Manual |

Fine drilling tasks with smaller capacities |

| C | Drilling: 18-30 mm Tapping: M14-M25 |

Drilling: Manual Tapping: Manual |

General-purpose drilling with manual control |

| TS | Drilling: 25-30 mm Tapping: M22-M25 |

Drilling: Manual Tapping: Manual |

Flexible use with manual feed |

| TSA | Drilling: 25-30 mm Tapping: M22-M25 |

Drilling: Automatic Tapping: Automatic |

Flexible use with automatic feed |

| TSA-TSE | Drilling: 32-35 mm Tapping: M28-M30 |

Drilling: Automatic Tapping: Automatic |

Automated operations requiring robust performance |

| TSA-TSE.40-45 | Drilling: 40-45 mm Tapping: M32-M35 |

Drilling: Automatic Tapping: Automatic |

Heavy-duty drilling and tapping with high capacity |

| TCA-TCE | Drilling: 40-70 mm Tapping: M33-M50 |

Drilling: Automatic Tapping: Automatic |

Very large and heavy-duty drilling and tapping applications |

| TH | Drilling: 40-50 mm Tapping: M36-M42 |

Drilling: Automatic Tapping: Automatic |

High-capacity, precision drilling |

| V-VP | Drilling: 32-40 mm Tapping: M24-M32 |

Drilling: Manual/Automatic Tapping: Manual/Automatic |

Professional use with manual or automated feed |

| V-VP 35 | Drilling: 35 mm Tapping: M27 |

Drilling: Manual/Automatic Tapping: Manual/Automatic |

Versatile professional drilling |

| G-GP | Drilling: 32 mm Tapping: M24 |

Drilling: Manual/Automatic Tapping: Manual/Automatic |

Reliable professional use |

| GP 40-50 | Drilling: 40-50 mm Tapping: M30- M35 |

Drilling: Automatic Tapping: Automatic |

Heavy-duty professional applications |

| TF | Drilling: 35 mm Tapping: M35 |

Drilling: Automatic Tapping: Automatic |

High-precision drilling and milling |

Pillar Drills Tailored To Your Workspace

- Versatile Applications: Our range includes everything from the workshop drill to industrial drills for sale, ensuring we have the perfect fit for your metalworking, woodworking, or any other drilling requirement.

- Customisation & Accessories: With adjustable and tilt-able worktables, plus a variety of tooling options, our machines are as adaptable as they come. Popular accessories include vices, collets, and chucks, enhancing your machine’s versatility.

- Safety & Compliance: Safety is our top priority. All models are CE certified, featuring separate emergency stops for worry-free operation.

Why Choose Workshop Press For Your Pillar Drill?

- Unmatched Quality: Every drill machine we offer is built to the highest standards, ensuring you get a product that not only meets but exceeds expectations.

- Industry Expertise: Leverage our expertise to find the ideal drill for sale that meets your specific needs, backed by our comprehensive after-sales support.

- Competitive Pricing: Get the best value for your investment with our competitively priced range, designed to last and backed by a 2-Year Warranty.

Pillar Drill Presses: The Essential Tool for Precision and Power

Whether you’re searching for the best drill to enhance your DIY projects or an industrial drill UK businesses rely on for heavy-duty tasks, Workshop Press is your go-to destination. Discover how our machines bring unparalleled accuracy and efficiency to your work.

Differentiating Between Professional and Industrial Pillar Drills

When differentiating between a professional and an industrial drill press, it’s important to consider their intended use, construction, and capabilities. Industrial pillar drills are specifically designed for heavy-duty applications and continuous use in demanding environments such as metal fabrication shops and manufacturing plants. They feature powerful motors, advanced gear-driven mechanisms, and enhanced durability to handle larger drill bits and tougher materials with precision and reliability. In contrast, professional pillar drills are built for regular but not continuous use, offering robust construction and user-friendly features suitable for workshops, small businesses, and educational institutions. Understanding these distinctions helps in selecting the right drill press for your specific needs.

Ready to Elevate Your Drilling Capabilities?

Browse our selection today and find the pillar drill that’s right for you.

For queries or to discuss your specific needs, don’t hesitate to get in touch.

Call us toll-free at 0800 999 1090. Let’s drill down to precision together with Workshop Press.