A Selection Of Hydraulic Presses At Workshop Press

Industrial Hydraulic Press Machines

At Workshop Press, hydraulic presses are available in a variety of sizes, frameworks, control sets, and tonnage capacities. Furthermore, we can customise presses to meet specific applications and needs. As hydraulic presses are frequently in use for certain industrial applications, it’s critical to talk to the technical sales engineer about the uses you desire. In addition to check that the machine is suitable for the job.

One of the most crucial factors is frame structure. The way a machine’s structure is built will determine whether it can withstand years of use. The machine could be a common model or a one-of-a-kind creation (designed and manufactured specifically). Here are a selection of industrial hydraulic presses types we offer.

Hydraulic Presses Range

ADVANTAGES OF HYDRAULIC PRESSES

-

Tonnage Consistency

Anywhere along the stroke, a hydraulic press can create complete pressing force. This provides you more control over the distance travelled, the pressure applied, and the position in which you return.

-

Customisation / Bespoke

Even the most difficult items may be pressed with industrial hydraulic presses. In addition, we can make changes to an existing design or create a bespoke press to match your specific needs.

-

Small Footprint

Presses can apply a lot of pressure to a tiny area. Therefore, they take up far less space than many other machines in the industry.

-

Economical

Because of the hydraulic press’s simplicity, they rarely break down, resulting in lower maintenance costs. However, if it does go down, though, parts are inexpensive and simple to replace.

-

Longer Tool Life

The hydraulic press tool, not the press, is tailored to fit the application. Overload prevention helps to protect tooling from damage, extending tool life.

WORKSHOP PRESSES

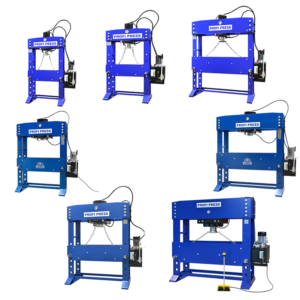

H-Frame Presses: The Powerhouse of the Workshop

H-frame presses, also known as Workshop Presses, are a versatile and powerful tool that can be used for a variety of tasks in the workshop. They are designed to deliver a specific amount of force to a specific location, and they can be used to bend, shape, and form metal, plastic, and other materials.

Also known as Hydraulic H-Frame Presses or Bearing Presses, they have uses including metalwork bending and folding, holding welding projects, punching, straightening uneven metal parts, bearing pressing, pressing locked parts, flattening warped parts, separating rusted parts, compressing, crushing used oil filters to remove excess oil, automobile part construction, jewellery-making, ammunition, and bracket bending.. They are, nevertheless, extensively employed in workshops for bearing pressing and straightening.

H-frame presses are powered by a hydraulic system, which means that they can generate a lot of force with a relatively small amount of input power. This makes them ideal for use in small workshops and home-based businesses, where space and power are limited.

H-frame presses are available in a variety of sizes and capacities, so you can choose the one that is right for your needs. They are also available with a variety of features, such as adjustable tables and programmable controls.

If you are looking for a powerful and versatile tool for your workshop, an H-frame press is a great option. They are easy to use and maintain, and they can save you time and money on a variety of projects.

Motorised Hydraulic Workshop Presses

30 Ton Motorised – Fixed Cylinder, 2 Speeds, 750 mm working width

60 Ton Motorised – Fixed Cylinder, 2 Speeds, 750 mm working width

100 Ton Motorised – Movable Cylinder, 2 Speeds, 1100 or 1500 mm working width

160 Ton Motorised – Movable Cylinder, 2 Speeds, 1100 or 1500 mm working width

200 Ton Motorised – Movable Cylinder, 2 Speeds, 1300 mm working width

300 Ton Motorised – Movable Cylinder, 2 Speeds, 1750 mm working width

Manual Hydraulic Workshop Presses

15 Ton Manual – Fixed Cylinder, 560 mm working width, V-Blocks Included

30 Ton MotorisedFixed Cylinder, 565 mm working width, V-Blocks Included

50 Ton MotorisedFixed Cylinder, 750 mm working width, V-Blocks Included

Hydraulic Workshop Presses and H-Frame Presses have uses including metalwork bending and folding, holding welding projects, punching, straightening uneven metal parts, bearing pressing, pressing locked parts, flattening warped parts, separating rusted parts, compressing, crushing used oil filters to remove excess oil, automobile part construction, jewellery-making, ammunition, and bracket bending.. They are, nevertheless, extensively employed in workshops for bearing pressing and straightening.

The Workshop Press Company offers Motorised Workshop Presses with 3o, 60, 100, 160, 200, and 300 Tons within our standard offering, but bepoke models and features are also available upon request. The 100 ton and 160 ton motorised models have a wide version with a working table of 1500 mm wide. A Broaching Press 15 ton motorised model is also offered. Manual versions come in 15, 30, and 50 tons.

***Bespoke models and features are also available upon request.

C-FRAME HYDRAULIC PRESSES

Also commonly referred to as Gap Frame Presses have a frame that is unique and results in the formation of a “C” around the bolster and slide plate which comprise the working area of the press. Floor-type model C-frame presses can deliver large tonnages while maintaining a footprint that is small and compact. C-Frame Presses come in standard configurations but are also customisable to specifically suit the customer’s needs.

The Workshop Press Company offers a wide variety of C-Frame Press categories and respective models.

The C Frame Press Categories Are:

PPC Series

The PPC series is a small footprint C-Frame Press with a Siemens NC controller that controls the top position or the return position of the piston and the bottom outward position, the difference between these two positions is the programmed piston stroke. The piston has a receiver where tools can be mounted and secured with integrated set screws. The bolster table has DIN-650 T-Slots and a centre hole. There are several operating modes and the piston is advance and returned with a foot pedal.

Models in the PPC Series Include:

- PPC-28 – 28 Ton C-Frame Press

- PPC-50 – 50 Ton C-Frame Press

- PPC-80 – 80 Ton C-Frame Press

PPCD Series

The PPCD Series is similar to the PPC series but has a heavier and larger framework and comes with side curtains and the stroke is controlled with easy to set micro-switches. The PPCD Series has a main piston and comes with larger bolster tables outfitted with DIN-650 T-Slots. The piston advance is controlled with palm buttons.

Models in the PPCD Series Include:

- PPCD-25 – 28 Ton C-Frame Press

- PPCD-50 – 50 Ton C-Frame Press

- PPCD-80 – 80 Ton C-Frame Press

- PPCD-100 – 100 Ton C-Frame Press

- PPCD-150 – 150 Ton C-Frame Press

PPCM Series

The PPCM Series is a more advanced, but economical series with a heavy framework and comes with side curtains with integrated safety light curtains. The stroke is controlled with easy to set micro-switches. The PPCM Series has and upper slide table and a lower bolster table both are outfitted with DIN-650 T-Slots. The piston advance is controlled with foot pedals that have an integrated E-Stop.

Models in the PPCM Series Include:

- PPCM-50 – 50 Ton C-Frame Press with bolster and slide tables.

- PPCD-80 – 80 Ton C-Frame Press with bolster and slide tables.

- PPCD-100 – 100 Ton C-Frame Press with bolster and slide tables.

- PPCD-150 – 150 Ton C-Frame Press with bolster and slide tables.

PPCF Series

The PPCF Series is yet again a more advanced series with a heavy framework, side curtains with integrated light safety curtains, and a state-of-the-art Siemens controller which controls all operating features of the press. The PPCF Series has and upper slide table and a lower bolster table both are outfitted with DIN-650 T-Slots. The piston advance is controlled with foot pedals that have an integrated E-Stop.

Models in the PPCF Series Include:

- PPCF-80 – 80 Ton C-Frame Press with bolster and slide tables and Siemens Controller.

- PPCF-100 – 100 Ton C-Frame Press with bolster and slide tables and Siemens Controller.

- PPCF-150 – 150 Ton C-Frame Press with bolster and slide tables and Siemens Controller.

PPCT Series

The PPCT Series is yet again a more advanced series with a heavy framework, side curtains with integrated light safety curtains, and a state-of-the-art Beijer controller which controls all operating features of the press. The Fast Advance feature can be controlled with the NC controller. The PPCT Series has and upper slide table and a lower bolster table both are outfitted with DIN-650 T-Slots. The piston advance is controlled with palm buttons that have an integrated E-Stop.

Models in the PPCT Series Include:

- PPCT-30 – 80 Ton C-Frame Press.

- PPCT-60 – 100 Ton C-Frame Press.

- PPCT-100 – 100 Ton C-Frame Press.

- PPCT-150 – 150 Ton C-Frame Press.

- PPCT-200 – 250 Ton C-Frame Press.

- PPCT-300 – 300 Ton C-Frame Press.

All PPCT models come with a bolster and slide tables and Beijer Controller.

C-Frame Presses are useful in every factory or workshop and are not only useful for mild steel but a variety of other materials also such as copper, brass, stainless steel, and carbide. C-Frame presses are used for punching, pressing, coining, straightening, forming, bending and, drawing and are useful in every industry. The RHTC C Frame presses come equipped with standard tools, but custom tools are also available from WorkshopPress.co.uk and we can use our in-house 3D manufacturing capabilities to assist in the design of custom press tools to suit your application.

All C Frame Presses are manufactured according to the latest CE Regulations and Directives and with top-quality steel and components and include a standard Manufacturer’s Warranty.

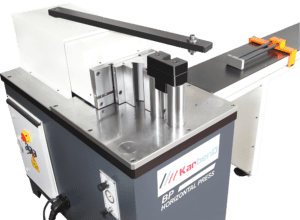

Standard Models

- HPB-10 – 10 Tons Horizontal Press Brake with standard control.

- HPB-20 – 10 Tons Horizontal Press Brake with standard control

- HPB-30 – 10 Tons Horizontal Press Brake with standard control

- HPB-40 – 10 Tons Horizontal Press Brake with standard control

- HPB-50 – 10 Tons Horizontal Press Brake with standard control

- HPB-80 – 10 Tons Horizontal Press Brake with standard control

- HPB-100 – 10 Tons Horizontal Press Brake with standard control

- HPB-150 – 10 Tons Horizontal Press Brake with standard control

Touchscreen Models

- HPB-10-NC – 10 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-20-NC – 20 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-30-NC – 30 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-40-NC – 40 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-50-NC – 50 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-80-NC – 80 Tons Horizontal Press Brake with Touchscreen Control.

- HPB-100-NC – 100 Tons Horizontal Press Brake with Touchscreen Control.

***Bespoke Sizes and configurations are available.

Touchscreen & Positioning Table Models

- HPB-10-NC-PT – 10 Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-20-NC-PT – 20Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-30-NC-PT – 30Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-40-NC-PT – 40Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-50-NC-PT – 50 Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-80-NC-PT – 80 Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

- HPB-100-NC-PT – 100 Tons Horizontal Press Brake with Touchscreen and integrated positioning table.

DEEP DRAWING PRESSES

RHTC Hydraulic Deep Drawing Presses: The Perfect Solution for Your Production Needs

RHTC hydraulic deep drawing presses are the perfect solution for a variety of production needs. With large table sizes and accelerated speeds, these presses can handle even the most demanding deep drawing applications. Deep Drawing Presses are available in a wide range of sizes and capacities starting at 100 ton and working up to 2000 tons and beyond. So, at The Workshop Press Company you can find the perfect press for your specific needs. The presses are also equipped with a variety of features that make them easy to use and maintain, including a main upper cylinder and a hydraulic cushion integrated into the lower bolster table of the pressing machine, a forming die set that dictates the shape of the resulting pressing, and a control panel that allows you to easily program the power, the cylinder stroke and pressure-time

Hydraulic deep drawing presses are used in a variety of industries, including such as Automotive, Medical, Aerospace, Appliances and White Goods, and Construction.

If you are looking for a high-quality, reliable deep drawing press, then we can offer the perfect choice for you. Contact us today to learn more about our products and services.

100 to 400 Ton Models offered in Deep Drawing Presses:

HDDT-100 – 100 Ton Deep Drawing Press – 800 x 1000 mm tables, 1000 mm Vertical Daylight

HDDT-200 – 200 Ton Deep Drawing Press – 800 x 1000 mm tables, 1000 mm Vertical Daylight

HDDT-300 – 300 Ton Deep Drawing Press – 1000 x 1200 mm tables, 1000 mm Vertical Daylight

HDDT-400 – 400 Ton Deep Drawing Press – 1200 x 1400 mm tables, 1000 mm Vertical Daylight

500 and 600 Ton Models offered in Deep Drawing Presses:

HDDT-100 – 100 Ton Deep Drawing Press – 800 x 1000 mm tables, 1000 mm Vertical Daylight

HDDT-200 – 200 Ton Deep Drawing Press – 800 x 1000 mm tables, 1000 mm Vertical Daylight

HDDT-300 – 300 Ton Deep Drawing Press – 1000 x 1200 mm tables, 1000 mm Vertical Daylight

HDDT-400 – 400 Ton Deep Drawing Press – 1200 x 1400 mm tables, 1000 mm Vertical Daylight

HDDT-500 – 500 Ton Deep Drawing Press – 1200 x 1500 mm tables, 1000 mm Vertical Daylight

HDDT-600 – 600 Ton Deep Drawing Press – 1500 x 1700 mm tables, 1000 mm Vertical Daylight

C-FRAME MECHANICAL PRESSES

Mechanical C-Frame Presses are very similar to Hydraulic C-Frame presses in that they structural press framework, which is manufactured out of S355JR steel, form a C around the bottom bolster of the press.

The primary differences between a industrial Mechanical C-Frame Presses and Hydraulic C-Frame presses are the drive mechanisms that move the top slide plate of the press. With the Mechanical Gap Frame Presses the slide plate is driven by a central motorised that has a lubrication system and an overload protection and then works in conjunction with an electro-pneumatic clutch-brake combination.

The electro-pneumatic clutch and brake combination are equipped with a dual safety solenoid valve. This pneumatic system includes a compensation tank, a regulator-lubrication filter, and a control pressure switch.

All of the PPE Series C-Frame Presses are high speed presses that conform with all the latest CE Machinery Directives.

Mechanical C Frame Press Series: PPE, PPE-4, and PPE-6

Mechanical C Frame Press PPE Series

The PPE Series mechanical presses are suitable to carry out tasks involving deep-drawing, cutting, punching, and stamping. These types of high-performance power presses can be used for many different tasks in many different industries.

Features and Accessories

Other features of the PPE Series Mechanical Presses are two lateral protection screens with level IV safety light guards, programmable control system (PLC), adjustable stroke, anti-vibration pads, and operation by means of a two-hand push or foot pedal controls.

As with any press that we offer, there is a wide variety of optional accessories and features available. Some examples of bespoke features are, pneumatic or hydraulic die ejectors or cushions, lower auxiliary table, strain gauge system, and NC digital displays with memories to save various working cycles. All presses are customisable to suit the customer’s requirements.

Technical Specifications

All presses have a variety of different technical specifications, but some of the common ones are how much pressure force the press delivers, the size of the main motor, and throat depth which is the depth from the front of the bolster table to the back of the press framework and this dimension determines how deep your die sets and workpieces can be.

Other technical specifications to consider are such items as strokes per minute, stroke adjustment, shut height, distance between table and ram, ram adjustment distance, table sizes (bolster and slide), working height of the bolster table, overall length width and height, and overall weight of the machine.

PPE Models

- PPE-30 – 30 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, Singular ram

- PPE-40 – 40 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, Singular ram

PPE-4 Models

- PPE-4-40 – 40 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-60 – 60 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-80 – 80 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-100 – 100 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-125 – 125 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-160 – 160 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-200 – 200 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-250 – 250 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

- PPE-4-315 – 315 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 4 Guides

PPE-6 Models

- PPE-6-40 – 40 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-60 – 60 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-80 – 80 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-100 – 100 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-125 – 125 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-160 – 160 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-200 – 200 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-250 – 250 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

- PPE-4-315 – 315 Tons with Electro-pneumatic Clutch and Brake, Adjustable Stroke, 6 Guides

FOUR COLUMN HYDRAULIC PRESSES

Four Column Hydraulic presses are a type of industrial hydraulic press, which as in the name, have four vertical chromed columns that keep the top slide plate perfectly square with the bottom bolster plate. Common applications for Four Column Presses are forming, drawing, bending, folding, stamping, hydro-forming, flanging, and punching. Four column presses come in a variety of tonnages with standard models ranging from 50 tons up to 300 tons, and bespoke tonnages are available.

The 5 Standard Models are:

- PPMV-50 – 50 Ton Four Column Press

- PPMV-80 – 80 Ton Four Column Press

- PPMV-100 – 100 Ton Four Column Press

- PPMV-150 – 150 Ton Four Column Press

- PPMV-220 – 220 Ton Four Column Press

- PPMV-300 – 300 Ton Four Column Press

Standard models come with micro-switch stroke control that control the overall length of the cylinder stroke to accommodate varying applications and the related press tools. The slide table and bolster table come with DIN-650 T-Slots to facilitate fixturing and securing of press and other tools. The Four Column Presses can be operated in manual, semi-automatic, and automatic modes, and have two speeds; fast advance mode and then working mode. Each press has a different maximum opening height that is called vertical daylight.

Customisations and bespoke features such as advance and working Speed Enhancement, NC or CNC Controller, System Input/Output Integration Interfaces, table sizes, Special Table Grooves or holes, Footprint size, Overall Press Configuration, Hydraulic Cooling System, Special Controls Integration, Special Table Guides Table Cushion, Knock-out apparatus, and many others. All Four Column Press Models are built in the EU, are CE Certified, and come with a manufacturer’s warranty.

CAMBERING HYDRAULIC PRESSES

Profi Press Hydraulic Cambering Presses are available in three tonnages. They each have their own supporting back tables and main pushing table. Also, T-Grooves and support blocks are included with both tables. These Cambering Presses are built in the EU from S355JR steel, with an electro-welded horizontal structure that is extremely strong.

Furthermore, the pushing tables are perfectly aligned at all times thanks to four cylindrical lateral guides. These horizontally oriented cambering machines make loading huge bars, beams, and profiles much easier. Additionally, there are two speeds on all presses: a quick approach speed and a working speed.

PRODUCTION HYDRAULIC PRESSES

Profi Press industrial Hydraulic Production Presses are available in a variety of tonnages, as well as different sizes of vertical and front holes. Slide and bolster tables of various sizes are also available.

Production presses are made of S355JR steel by RHTC. This results in an electro welded structure that will last a lifetime. T-grooves are standard on the lower bolster table and upper slide table. Four cylindrical lateral guides keep the top slide completely parallel. Consequently, ensuring that the upper table is perfectly aligned.

Moreover, the upper table’s position is easily adjustable and controlled from a side panel. There are two speeds on all production presses.

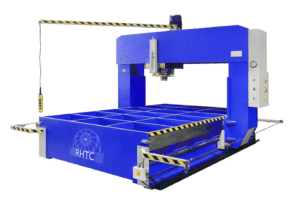

PORTAL PRESSES

Roll Frame Presses are the most common name for these presses. They resemble Workshop Presses in appearance. However, they add another axis of accessibility. For instance, they let the head to move from front to rear as well as from left to right. The working table on portal presses is quite large. 1.5 metres broad and 3 metres deep, for example.

Straightening techniques on huge plates, large sheets, wide beams, railways, and pipes are ideally adapted to them.