DEMAE Series Compact Coil Feeding Line from LARA

Product Code: DEMAE SeriesThe European-built DEMAE Series Compact Coil Feeding Line from LARA is a state-of-the-art addition to your industrial hydraulic press setup. As a leading solution in coil feeding technology, this machine is meticulously designed to handle a diverse range of coil sizes, enabling efficient processing, stamping, and forming of metal. Its feed accuracy of +- 0.05mm is a testament to its precision, making it a high-precision coil feeder that ensures flawless operation in every production run. The DEMAE Series , a heavy-duty coil feeder, is equipped with a motorized vertical decoiler and a pneumatic clamping arm, both optimized to streamline the coil feeding process. The machine's robust construction and high-quality materials not only ensure durability but also promise minimal maintenance, making it a reliable choice for high-volume production runs. DEMAE Series is a testament to engineering excellence, designed to enhance productivity and reduce downtime in any industrial setting. It is CE marked, ensuring it meets high safety, health, and environmental protection requirements. The DEMA 61/300 high-precision coil feeders is equipped with a 'Motion-Drive' digital servo-controller for processes with repetition of the feed length, an external encoder, and a connection cabinet with all necessary auxiliary protection equipment for correct operation. They are designed for easy installation and minimal maintenance, making them a reliable choice for any industrial setting. Their efficient operation and precision make them an invaluable addition to your hydraulic press system, enhancing productivity and reducing downtime. Their innovative design and superior functionality make them an essential component in the modern industrial landscape.

Please contact for prices

- Description

- Additional Info

Pneumatic Clamping Arm

Our pneumatic clamping arm features a sturdy, welded structure with a central axis in high-resistance steel. It incorporates a nylon-coated wheel with maintenance-free ball bearings, ensuring smooth rolling without marking the sheet metal. The adjustable arm allows easy alignment with various coil widths.

Electronic Controls Features

- Main On/Off switch

- Automatic / Manual Mode Selector

- Direction of Rotation selector

- Manual Feed Button

- Emergency Stop

- Loop Excess Control Start/Stop timer

- Touchscreen HMI Control

- Programmable Feed Length up to 9999 mm

- Programmable Speed in Percentages

- Diagnosis Display of Error Messages

- Function Parameters

Series General Features

-

- Motorized Decoiler with Mechanical Expansion

- Cold-rolled welded steel framework

- stabilized tubular steel structure

- The machine is easy to install and handle

- Low level maintenance requirements

- Central axis manufactured from treated steel.

- Steel mandrel, which is welded and stabilized.

- Coil fastening is achieved by means of 6 adjustable side arms

- Mechanical expansion of the mandrel driven by a threaded spindle and crank.

Straightener Feeder Features

Our space-saving straightener-feeder system simplifies installation and programming. You can easily handle the start-up process yourself, ensuring quick and safe operations. Thanks to our Motion-Drive electronic control system, the strip is precisely positioned during feeding with repetitive feed length accuracy.

- Robust construction and easy handling

- Rollers and gears made of special treated and rectified steel with a surface hardness of 60-62 HRC

- Main transmission by reducer

- Transmission between rollers through hardened spur gears

- Manual adjustment of the upper rollers by means of conical gears and threaded spindles

- Micrometric reading of straightening penetration

- Adjustable side guides at the entrance

- Support rollers at the entrance

- Adjustable pneumatic system for pilot release and raising the group of upper rollers, to facilitate the introduction of the material and for work with dies with centering pilots

- Variable feeding height from 1000 to 1150 mm

- ‘Motion-Drive’ digital servo-controller, for processes with repetition of the feed length

- External encoder

DEMAE 46 Series

The DEMAE 46 Series Compact Coil Feeding Lines, engineered by LARA for precision metal fabrication. Our diverse lineup, including the DEMAE 46/200, 46/300, 46/450, and 46/600 models, is designed to cater to a broad spectrum of industrial needs. Each model boasts exceptional handling with maximum coil weights ranging from 1,000 kg to 3,000 kg and accommodating widths from 200 mm to 600 mm. With internal and external diameter capacities consistent at 525 mm and up to 1400 mm respectively, our coil feeders are equipped to manage both standard and extensive coil sizes.

Precision is paramount in metal processing; hence, our feeders maintain a strict feed accuracy of ± 0.1 mm and a minimum material thickness capacity of 0.3 mm, ensuring your workpiece integrity is never compromised. The robust construction includes 90 straightening rollers and 7 motorized rollers with a diameter of 45 mm, complemented by a continuous speed of 60 m/min and an adjustable rotation speed ranging from 2 to 12 rpm for optimal control.

Each coil feeding line is meticulously designed for ease of operation, reliability, and integration into existing workflows, making them an ideal choice for metal fabrication professionals. Trust in the precision engineering of LARA’s DEMAE Series to elevate your manufacturing capabilities.

| MODEL | 46/200 | 46/300 | 46/450 | 46/600 |

|---|---|---|---|---|

| Max width (mm) | 200 | 300 | 450 | 600 |

| Max Coil Weight (kg) | 1000 | 1000 | 2000 | 3000 |

| Max Inside Diameter (mm) | 525 | 525 | 525 | 525 |

| Max Outside Diameter (mm) | 1200 | 1200 | 1400 | 1400 |

| Max opening of rollers (mm) | 3 | 3 | 3 | 3 |

| Max feed section 600/750 mm² | 200 x 3 | 300 x 2 | 450 x 1.5 | 600 x 1 |

| Recommended min. thickness (mm) | 0.3 | 0.3 | 0.3 | 0.3 |

| Motorized Pull Rollers (qty) | 2 | 2 | 2 | 2 |

| Straightening Rollers (qty) | 90 | 90 | 90 | 90 |

| Straightening Motorized Rollers (qty) | 7 | 7 | 7 | 7 |

| Straightening rollers diameter (mm) | 45 | 45 | 45 | 45 |

| Continuous speed (m/min) | 60 | 60 | 60 | 60 |

| Feed accuracy (mm) | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 |

| Rotation Speed (rpm) | 2 to 12 | 2 to 12 | 2 to 12 | 2 to 12 |

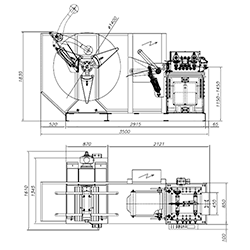

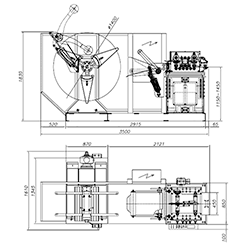

DEMAE 61 Series

The LARA DEMAE 61 Series Compact Coil Feeding Lines, a collection meticulously crafted for the discerning mechanical engineer. Spanning four models – the 61/300, 61/450, 61/600, and 61/750 – this series is the epitome of European engineering, designed to seamlessly integrate into your hydraulic press setups. With maximum widths ranging from 300mm to 750mm, they are capable of handling a variety of coil sizes, reinforcing versatility in your operations.

Each model ensures a high-precision feed accuracy of ±0.05mm, supported by robust construction and quality materials, promising longevity and minimal maintenance. The 60 mm diameter straightening rollers, coupled with a sophisticated ‘Motion-Drive’ digital servo-controller, assure impeccable material processing and feed repetition. CE marking across the range guarantees adherence to stringent safety, health, and environmental standards, making the DEMAE 61 Series a reliable and compliant choice for any industrial environment.

Opt for the LARA DEMAE 61 Series to harness efficiency, precision, and durability, and let your hydraulic press system evolve with the demands of modern metal fabrication

| MODEL | 61/300 | 61/450 | 61/600 | 61/750 |

|---|---|---|---|---|

| Max Width (mm) | 300 | 450 | 600 | 750 |

| Minimum Coil Diameter (mm) | 1400 | 1400 | 1400 | 1400 |

| Minimum Inside Diameter (mm) | 385 | 385 | 385 | 385 |

| Max Inside Diameter (mm) | 525 | 525 | 525 | 525 |

| Maximum Outside Diameter (mm) | 1400 | 1400 | 1400 | 1400 |

| Max Opening of Rollers (mm) | 4 | 4 | 4 | 4 |

| Max Feed Section 900 / 1200 mm² | 300 x 3 / 4 | 450 x 2 / 2.7 | 600 x 1.5 / 2 | 750 x 1.2 / 1.6 |

| Recommended min. Thickness (mm) | 0.5 | 0.5 | 0.5 | 0.5 |

| Straightening Rollers Diameters (mm) | 60 | 60 | 60 | 60 |

| Motorized Pull Rollers (qty) | 4 | 4 | 4 | 4 |

| Straightening Rollers (qty) | 7 | 7 | 7 | 7 |

| Straightening Motorized Rollers (qty) | 4 | 4 | 4 | 4 |

| Continuous Feed Speed (m/min) | 60 | 60 | 60 | 60 |

| Feed Accuracy (mm) | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 |

DEMAE 85 Series

| MODEL | 85/300 | 85/450 | 85/600 | 85/750 | 85/1000 |

|---|---|---|---|---|---|

| Maximum Width (mm) | 300 | 450 | 600 | 750 | 1000 |

| Minimum Opening of Rollers (mm) | 6 | 6 | 6 | 6 | 6 |

| Minimum Inside Diameter (mm) | 450 | 450 | 450 | 450 | 450 |

| Maximum Inside Diameter (mm) | 525 | 525 | 525 | 525 | 525 |

| Maximum Outside Diameter (mm) | 1600 | 1600 | 1800 | 1800 | 1800 |

| Maximum Coil Weight (Kg) | 3000 | 5000 | 6500 | 8000 | 8000 |

| Maximum Coil Width (mm) | 300 | 450 | 600 | 750 | 1000 |

| Variable Turning Speed (rpm) | 2-12 rpm | 2-12 rpm | 2-12 rpm | 2-12 rpm | 2-12 rpm |

| Maximum Feed Section (2250 mm²) | 300 x 6 | 450 x 5 | 600 x 3.75 | 750 x 3 | 1000 x 2.3 |

| Minimum thickness (mm) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Straightening Rollers (mm) | 85 | 85 | 85 | 85 | 85 |

| Motorized Pull Rollers (qty) | 4 | 4 | 4 | 4 | 4 |

| Straightening Rollers (qty) | 7 | 7 | 7 | 7 | 7 |

| Straightening Motorized Rollers (qty) | 4 | 4 | 4 | 4 | 4 |

| Continuous speed (m/min) | 60 | 60 | 60 | 60 | 60 |

| Feed Accuracy (mm) | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 |

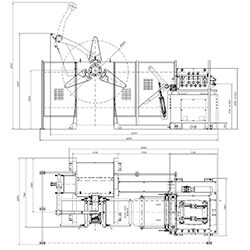

DEMAE 100 Series

Introducing the LARA DEMAE 100 Series Compact Coil Feeding Lines, the pinnacle of precision engineering for modern industrial metal forming. From the nimble DEMAE 100/300 to the expansive DEMAE 100/1500, this series covers a comprehensive range of coil widths, from 300mm to an impressive 1500mm, meeting the diverse needs of high-volume production facilities.

These European-built, CE-marked coil feeders are crafted to enhance the productivity of your hydraulic press operations, boasting a feed accuracy of ± 0.05mm for unparalleled precision. With a solid construction designed to handle coil weights up to 12,500kg and a continuous operational speed of 60 m/min, the DEMAE 100 series stands as a testament to durability and efficiency.

Each model is equipped with robust straightening rollers, motorized pull rollers, and a variable turning speed of 2 to 12 rpm, ensuring adaptability for various material specifications and processing requirements. The series emphasizes minimal maintenance and ease of operation, integrating ‘Motion-Drive’ digital servo-controllers for feed length repetition, highlighting the fusion of advanced technology and user-friendly design.

Choose the DEMAE 100 Series for your industrial setup and benefit from a seamless metal processing experience, characterized by high-speed operation, strategic automation, and a commitment to quality and safety. These coil feeders are not just machines; they are comprehensive solutions engineered to propel your production capabilities into the future of metal fabrication.

| MODEL | 100/300 | 100/450 | 100/600 | 100/750 | 100/1000 | 100/1250 | 100/1500 |

|---|---|---|---|---|---|---|---|

| Maximum Coil Width (mm) | 300 | 450 | 600 | 750 | 1000 | 1250 | 1500 |

| Minimum Opening of Rollers (mm) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Minimum Inside Diameter (mm) | 508 | 508 | 508 | 508 | 508 | 508 | 508 |

| Maximum Inside Diameter (mm) | 610 | 610 | 610 | 610 | 610 | 610 | 610 |

| Maximum Outside Diameter (mm) | 1600 | 1600 | 1600 | 1600 | 1800 | 1800 | 1800 |

| Maximum Coil Weight (Kg) | 5000 | 7500 | 10000 | 10000 | 12500 | 12500 | 12500 |

| Variable Turning Speed (rpm) | 2 to 12 | 2 to 12 | 2 to 12 | 2 to 12 | 2 to 12 | 2 to 12 | 2 to 12 |

| Maximum Feed Section (500 mpa 3000 mm²) | 300 x 10 | 450 x 6.7 | 600 x 5 | 750 x 4 | 1000 x 3 | 1250 x 2.4 | 1500 x 2 |

| Minimum thickness (mm) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Traction Rollers (mm) | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Straightening Rollers (mm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Motorized Pull Rollers (qty) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Straightening Rollers (qty) | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Straightening Motorized Rollers (qty) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Continuous Speed (m/min) | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Feed Accuracy (mm) | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 |

Coil Feeding System Inquiry Guidelines for Customers

To ensure we provide the most effective and efficient coil feeding system for your needs, we kindly ask you to provide detailed information about your requirements. The guide below is designed to help you identify and communicate the specific details of your project. This information will enable us to tailor our solutions precisely to your needs, ensuring optimal performance and satisfaction.

General Requirements:

- Space Dimensions: Specify the area available (length x width x height).

- Working Direction: Indicate preferred operational direction.

- Feeding Height: State the required height for material feeding.

- Voltage Requirements: Mention electrical specifications needed.

Material Details:

- Type of Material: Describe the material (steel, aluminum, etc.).

- Thickness Range: Provide the range of material thickness.

- Width Range: Indicate the width range of the material.

- Yield Strength: Specify the material’s yield strength.

Equipment Specifications:

- Decoiler Details: Include maximum coil weight and inner/outer diameter.

- Cart Options: Mention if a cart is required for coil handling.

Straightener and Feeder Specifications:

- Straightener Thickness Range: State the thickness range the straightener can handle.

- Feeder Speed: Indicate the required feeding speed.

- Advance Distance: Mention the advance distance per stroke.

Production Line Configuration:

- Configuration Type: Choose from options like compact, short, or long line.

- Part Description/Drawing: Provide a detailed description or a drawing of the production part.

Lara Spain, a leading name in the metal forming industry. With over 25 years of experience, Lara specializes in the design, manufacture, and installation of top-tier machinery for metal forming processes. Their product range includes Metal Coil Decoilers, Coil Straighteners, Coil feeders, and other essential equipment for Metal Strip Processing.

Lara serves a diverse range of industries using metal forming applications, including automotive, aerospace, and construction. Lara’s strong presence in the European and Global Metal Stamping market is a testament to their quality and reliability.

Why does The Workshop Press Company choose to sell LARA metal coil feeding systems? It is because Lara Spain has a proven record of combining expertise, quality, and service while delivering the best solutions for our customers’ metal forming requirements. Their team comprises of seasoned engineers that understand the unique challenges of the metal forming industry and they dedicated to providing the most effective solutions.

Lara’s products are crafted from the highest quality materials and components, and they undergo rigorous testing to ensure they meet or exceed our customers’ rigorous expectations. Lara’s commitment doesn’t end with product delivery because they offer a comprehensive range of services, including engineering, project management, and after-sales support, to help you maximize the value of your metal processing equipment.

The Workshop Press Company offers coil feeding systems from Lara Spain because they are reliable, high-quality metal forming machinery. Contact us today to learn more about our products and services.