- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

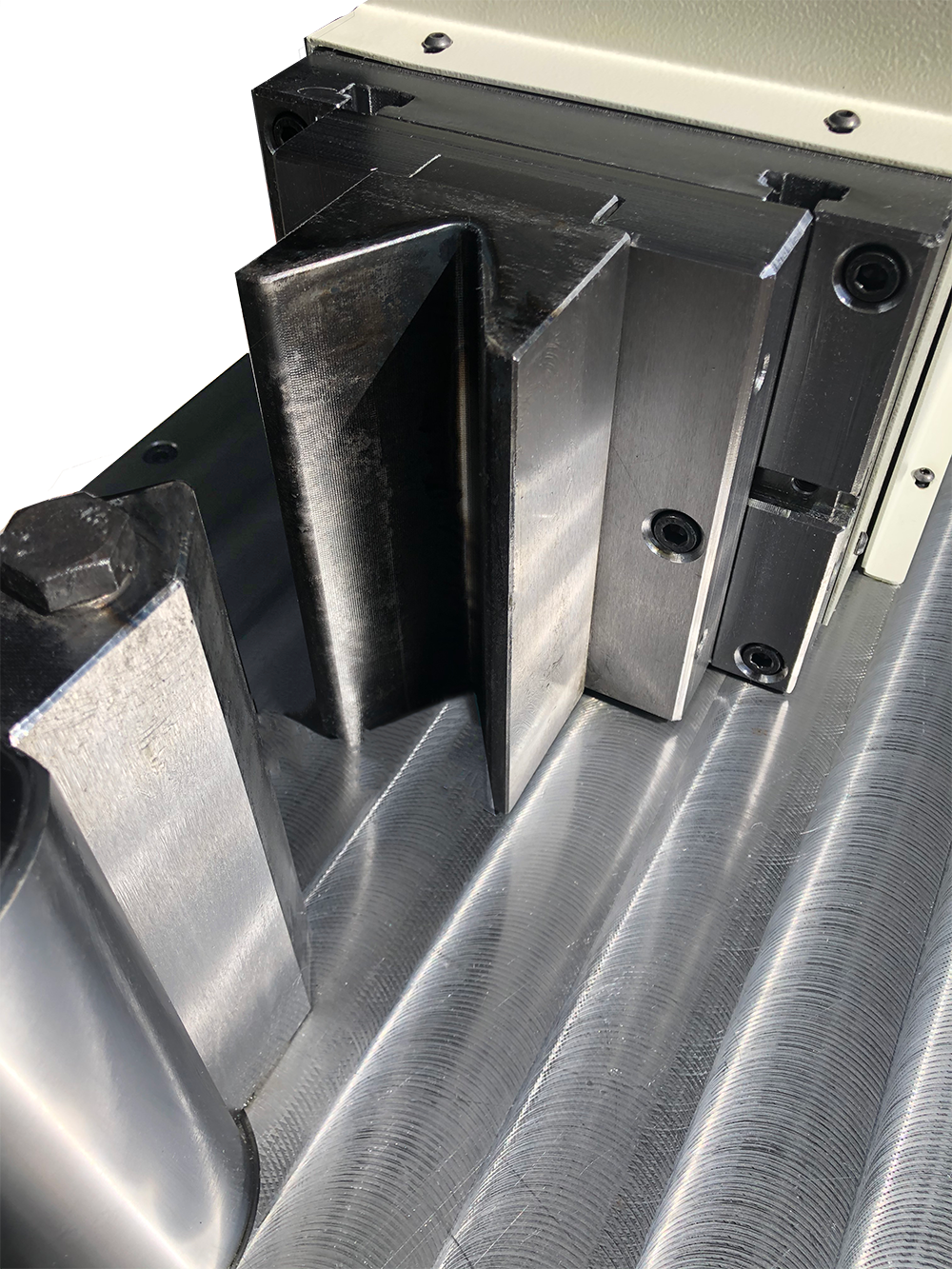

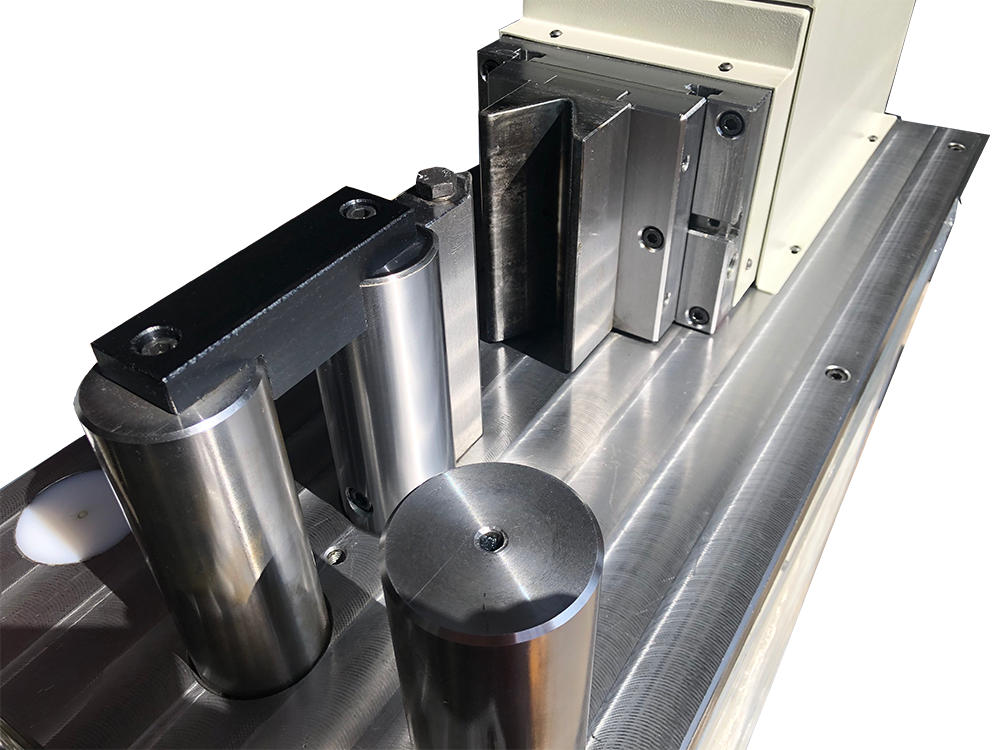

Horizontal Press Brake with NC Touchscreen Control with Automated Positioning Table

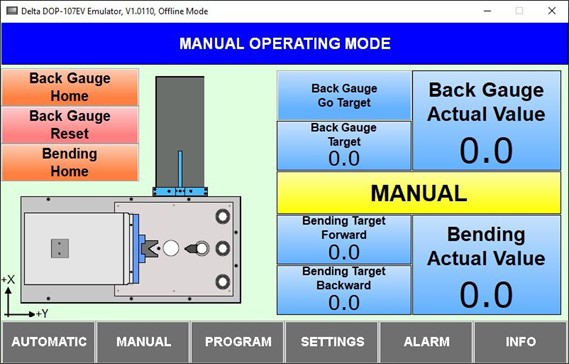

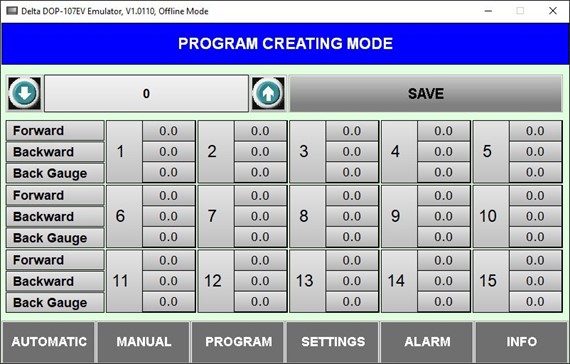

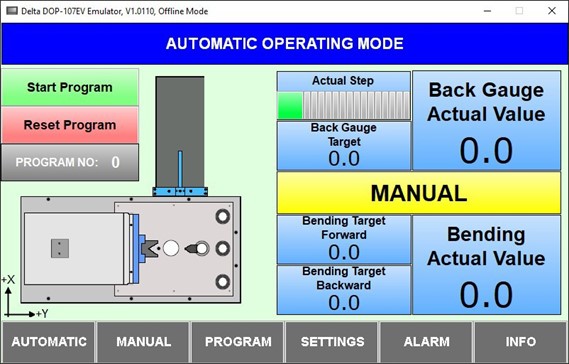

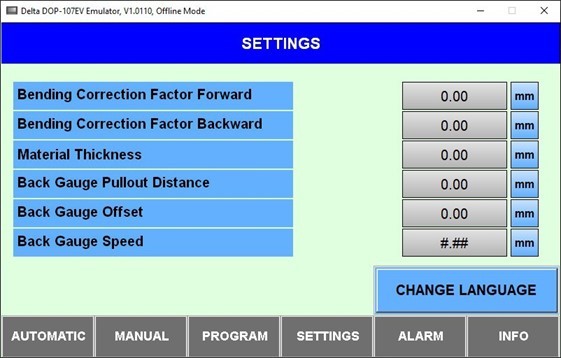

Product Code: HPB-NC-Control-PosTableThe Horizontal Hydraulic Press Machine, offered by WorkShopPress.co.uk, combines power and precision with its automated positioning table and NC touchscreen control system. The NC control provides storage for 20 different programs, with up to 15 steps per program. Operators can configure the length of the stroke, return position, and positioning stops, allowing for smooth sequential operations and reduced downtime.

Ideal for bending flat bars, round tubes, profiles, and sheet metal folding, this machine delivers a reliable solution for production and one-off custom bends. The programmable stops and positioning table, controlled directly through the touchscreen HMI, allow for maximum precision, making it perfect for industries where accuracy and repeatability are crucial. Additionally, a wide variety of tooling options are available, allowing for punching, crimping, and metal folding applications.

Designed for high-performance operations in manufacturing, metal fabrication, and construction industries, this hydraulic press is an essential piece of equipment for workshops needing efficiency, reliability, and flexibility.

Please contact for prices

- Description

- Additional Info

Capacity Table

Horizontal Press Brakes with Programmable Backgauge

| Specification/Model | BP 10 | BP 20 | BP 30 | BP 40 | BP 50 | BP 80 | BP 100 |

|---|---|---|---|---|---|---|---|

| Max Pressure (Tons) | 10 | 20 | 30 | 40 | 50 | 80 | 100 |

| NC Controller | 20 Programs/15 Steps each | 20 Programs/15 Steps each | 20 Programs/15 Steps each | 20 Programs/15 Steps each | 20 Programs/15 Steps each | 20 Programs/15 Steps each | 20 Programs/15 Steps each |

| Flat material: (mm) | 150 x 8 | 200 x 12 | 200 x 18 | 200 x 24 | 300 x 15 | On Request | On Request |

| Round Tubes: (mm) | 42 x 3.2 | 48 x 4.0 | 60 x 4.0 | 60 x 5.0 | 76 x 4.0 | On Request | On Request |

| Max Stroke (mm) | 185 | 185 | 285 | 285 | 285 | 285 | 285 |

| Pin Dia. (mm) | 60 | 80 | 80 | 80 | 90 | 105 | 105 |

| Tool Height (mm) | 150 | 200 | 250 | 250 | 300 | 300 | 300 |

| Working Speed (mm/sec) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Return Speed (mm/sec) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Motor (kW) | 1.1 | 2.2 | 3 | 4 | 5.5 | 10 | 10 |

| Oil Capacity (Litres) | 12 | 12 | 40 | 40 | 60 | 120 | 120 |

| Net Weight (kg) | 250 | 530 | 1050 | 1050 | 1450 | 1700 | 1700 |

| Table Size (L x W mm) | 450 x 900 | 480 x 1060 | 660 x 1250 | 660 x 1250 | 600 x 1250 | 750 x 1425 | 750 x 1425 |

| Working Height (mm) | 915 | 930 | 930 | 930 | 930 | 930 | 930 |

| Length (mm) | 900 | 1150 | 1250 | 1250 | 1400 | 1430 | 1430 |

| Width (mm) | 450 | 480 | 650 | 650 | 600 | 750 | 750 |

| Height (mm) | 1130 | 1200 | 1250 | 1250 | 1500 | 1450 | 1450 |

The Horizontal Hydraulic Press Machines from WorkShopPress.co.uk deliver precision, versatility, and ease of use for metalworking applications. Equipped with an advanced NC touchscreen control and automated positioning tables, these presses offer enhanced productivity for a wide range of bending, straightening, and punching operations. The NC touchscreen allows operators to store up to 20 programs with 15 steps each, enabling automated, repeatable workflows that reduce setup time and improve efficiency. Whether you’re bending flat bars, round tubes, or performing sheet metal folding, this machine provides the reliability and flexibility needed for small batch or high-volume production runs.

These horizontal presses are ideal for industries such as manufacturing, metal fabrication, and construction, where precise, repetitive operations are essential. Manual and program modes offer the adaptability needed to suit different production requirements, making these presses a powerful asset in any workshop.

Features

- NC Controller Holds 999 Programs, 15 Steps Each

- Adjustable Piston Stroke and Return by Step

- Manual and Automatic Program Modes

- Flow Adjustment Valve for Pressure

- Pressure Manometer

- Back Gauge

- V-Die (5 mm Radius)

- V-Die Receptor (86 mm Opening)

Optional Accessories

- Tool Set for Bending Tubes

- Tool Set for Bending Flat Bar the Hard Way

- Tool Set for Straightening Beams and Sections

- Tool for Bending Sheet Metal into Specific Shape

- Punching Tools

- Shearing Tools

Industries Using the Machine and Their Uses

- Metal Fabrication: Bending, punching, and cutting of profiles, tubes, and sheets

- Construction: Production of brackets, clips, and reinforcements for structural applications

- Manufacturing: High-volume, repeatable bending and straightening processes

- Automotive: Creation of custom parts and components for vehicle frames and chassis

- Aerospace: Precision bending and punching for lightweight metal components

Horizontal Hydraulic Press with automated positioning table and NC touchscreen control for precision metalworking applications, ideal for bending, straightening, punching, and shearing.