D53 / 25 – 320 • 50 Kg Capacity • 0.25 to 2.5 RPM • 320mm Working Height • 250mm Faceplate • 10mm Through Hole

Product Code: D53/25-320The D53 series are top quality German-built welding positioners for suitable for welding with electrodes, MIG, MAG-TIG, Plasma, and Plasma cutting.

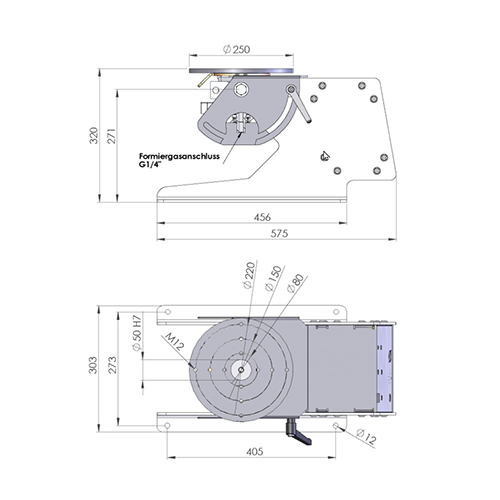

The model D53/25-320 Welding Positioner has a 250mm Face Plate Diameter, 50 Kg Load Capacity, 320 mm Working Height, and RPM Range of 0.25 to 2.5 revolutions per minute. It is made in Bavaria, Germany and has a 2-Year Warranty, and is CE Certified.

The D53 series comes in 2 different working heights and 2 different RPM Ranges other than that the rotary tables in this series are all the same.

It offers a hefty faceplate with a diameter of 250 mm and a tilt range of 135 degrees and can be set at any angle in that range. The D53 turntables come with a standard 10mm spindle bore, and the bore can be used for clamping long tubes, pipes, or profiles in a multi-jaw chuck or a jig. It can also be used for compressed air supply lines, cooling fluid supply, or for the supply of shielding gas to the welding job. The central bore on the faceplate has a diameter of 50mm and welders in a wide variety of industries use for this bore for centralising jigs, chucks, mounting weld pieces to the faceplate.

The Rotation speed is infinitely adjustable, and the drive has a 24 V DC-motor with a worm gear.

The control electronics of the unit are enclosed in a protective housing, and are conveniently positioned and accessible on the front panel of the rotary welding table. The speed controller and motor are electrically isolated from the mains and supplied with 24 V via a transformer. The current collector is insulated and can is rated to accept a maximum of 400 A/34 V at 80% duty cycle.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Model: D53/25-320

- Load Capacity (vertical): 50 kg/0.5 kN

- Speed RPM: 0.25 – 2.5/Minute

- Torque: 2.5 – 15 Nm

- Face Plate Diameter: 250 mm

- Table Working Height: 320 mm

- Axis height: 270 mm

- Through Hole Diameter: 10 mm

- Centralising bore (chuck or jig mount): ø 50H7

3 mm deep - Tilting angle – face plate: 135°

- Tilting operation: manual lockable

- Tilting moment: 90 Nm

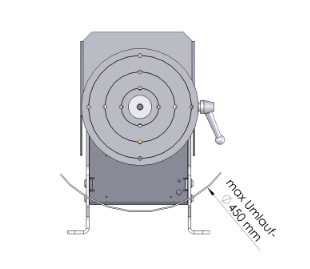

- Max. rotating diameter: 450 mm

- Current collector: 400 A (34 V) 80% duty cycle

- Mains voltage: 230 V / 240 V

- Frequency: 50 Hz

- Mains connection cable: 3 x 2.5 mm²,5 metre length with Schuko plug

- Interface for external operation: Foot switch, hand and foot remote

- Speed control range: 1:10

- Limit switch overlap 360° + overlap: no

- Weight: 33 kg

The Welding Positioner Controls include a mains power switch which turns the overall power on/off, a push-button on/off switch for the rotation function, a button to control the rotational direction in a clockwise or anti-clockwise direction, a potentiometer to control the turntable revolutions per minute (RPM), a coding switch to control 2 stroke or 4 stroke functionality, and a 10 pin plug that allows for optional extras such as foot control switch, remote switch, or remote control.