- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

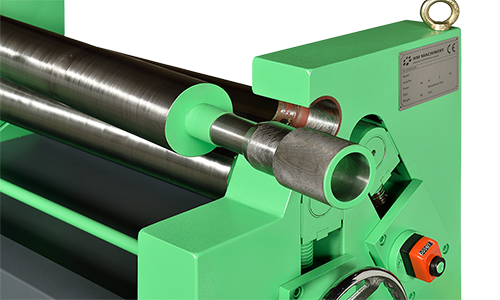

MRM 1550 Series Plate Rolls • 1550 mm Working Length • 130 to 190 mm Roll Diameter • 6 to 9 mm Capacity

Product Code: MRM-1550-XXXExplore the advanced MRM 1550 Series Plate Rollers, engineered for superior performance and precision in metal bending. With models that support mild steel capacities ranging from 6.0 mm to 9.0 mm, these machines are designed for durability and ease of use. Perfect for applications involving aluminum, air conditioning channels, advertising panels, and sheet metal covers, the MRM 1550 series ensures efficient operation across various industries.

Please contact for prices

- Description

- Additional Info

The MRM 1550 Series Plate Rollers boast robust construction with solid steel gable-ends and a modern, clean surface design. These machines handle sheet sizes up to 1550 mm in width and up to 9.0 mm in thickness for mild steel. Featuring an independently mounted three-roll design, they provide high productivity with easy roll adjustments. Both upper and lower rolls are driven to prevent material marking through slipping, and the high-polish finish protects pre-finished components, even those made from highly sensitive materials.

Key features include the easy removal of the finished tube by swinging out the top roll, motorized adjustment of the back roll, and a mobile control panel with a three-position foot pedal, including an emergency stop.

Technical Specifications

- Working Length: 1550 mm

- Mild Steel Capacity: 6.0 mm to 9.0 mm

- Prebend: 6 mm to 9 mm

- Minimum Bending Diameter: 150 mm to 205 mm

- Rolls Diameter: 130 mm to 190 mm

- Rolls Speed: 6.0 m/min to 6.5 m/min

- Motor Power: 2.00 / 0.75 kW to 3.75 / 1.5 kW

- Dimensions (L x W x H): 2320 x 660 x 1050 mm to 2520 x 800 x 1200 mm

- Weight: 1500 kg to 2100 kg

Features and Uses

- Easy removal of finished tube by swinging out the top roll

- Solid steel gable-ends with modern design

- High polished finish to prevent damage to sensitive materials

- Ideal for aluminum, air conditioning channels, advertising panels, and sheet metal covers

- Motorized adjustment of back roll with mm counter

- Mobile control panel with 3 position foot pedal and emergency stop

- Built to comply with current EC Safety Directives (CE marked)

Industries Using the Machine and Their Uses

- Metal Fabrication: Sheet bending and forming

- HVAC: Air conditioning channel production

- Advertising: Panel and sign manufacturing

- Sheet Metal Covers: Precision bending for covers and enclosures

Standard Equipment

- Asymmetrical initial pinch rolls

- Upper and lower rolls driven via hardened gear system

- Standard alloy-steel rolls

- Motorized adjustment of back roll with mm counter for accurate bending

- Solid steel gable-ends

- Top roll to slip with mechanical manual drop-end

- Mobile control panel with 3 position foot pedal (including emergency stop)

- Conical Bending Device

- Precision bending through heavy-duty brake motor

- Built to comply fully with current EC Safety Directives (CE marked)

Optional Equipment

- Digital read-out for rear (back) roll

- Hardened rolls

| Specification | MRM 1550-130 | MRM 1550-150 | MRM 1550-170 | MRM 1550-190 |

|---|---|---|---|---|

| Article Number | 14110740 | 14110750 | 14110760 | 14110770 |

| Working Length [mm] | 1550 mm | 1550 mm | 1550 mm | 1550 mm |

| Mild Steel Capacity [mm] | 6.0 mm | 7.0 mm | 8.0 mm | 9.0 mm |

| Prebend (mm) | 6 | 7 | 8 | 9 |

| Min. Bending Diameter [mm] | 150 | 170 | 190 | 205 |

| Rolls Diameter [mm] | 130 | 150 | 170 | 190 |

| Rolls Speed [m/min] | 6.5 m/min | 6.0 m/min | 6.0 m/min | 6.0 m/min |

| Motor [kW] | 2.00 / 0.75 | 3.75 / 1.1 | 3.75 / 1.1 | 3.75 / 1.5 |

| L x W x H | 2320 x 660 x 1050 mm | 2320 x 680 x 1080 mm | 2420 x 700 x 1100 mm | 2520 x 800 x 1200 mm |

| Weight [kg] | 1500 kg | 1700 kg | 1900 kg | 2100 kg |

High-precision MRM 1550 Series Plate Rollers for accurate metal bending, suitable for mild steel and aluminum. Available in multiple capacities.