PBM-50-2 Profile Bender Manual 2 Driven Rolls – 1 Phase or 3-Phase

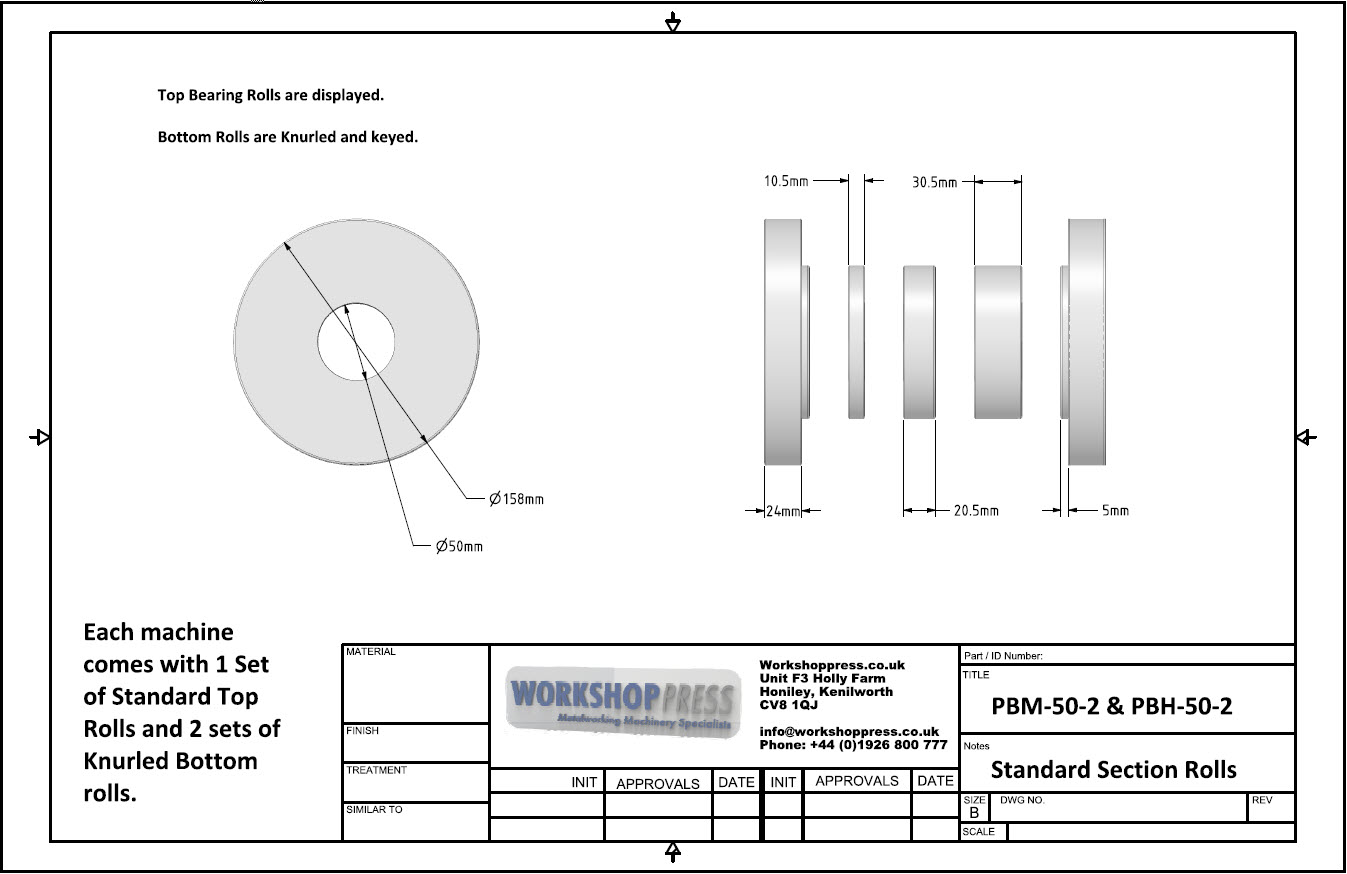

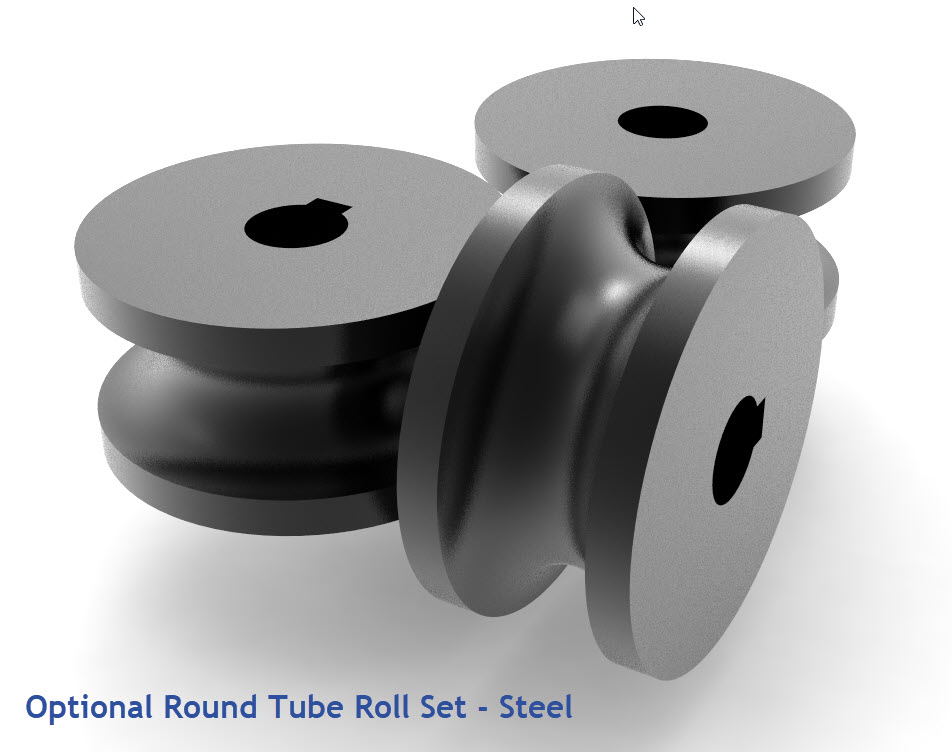

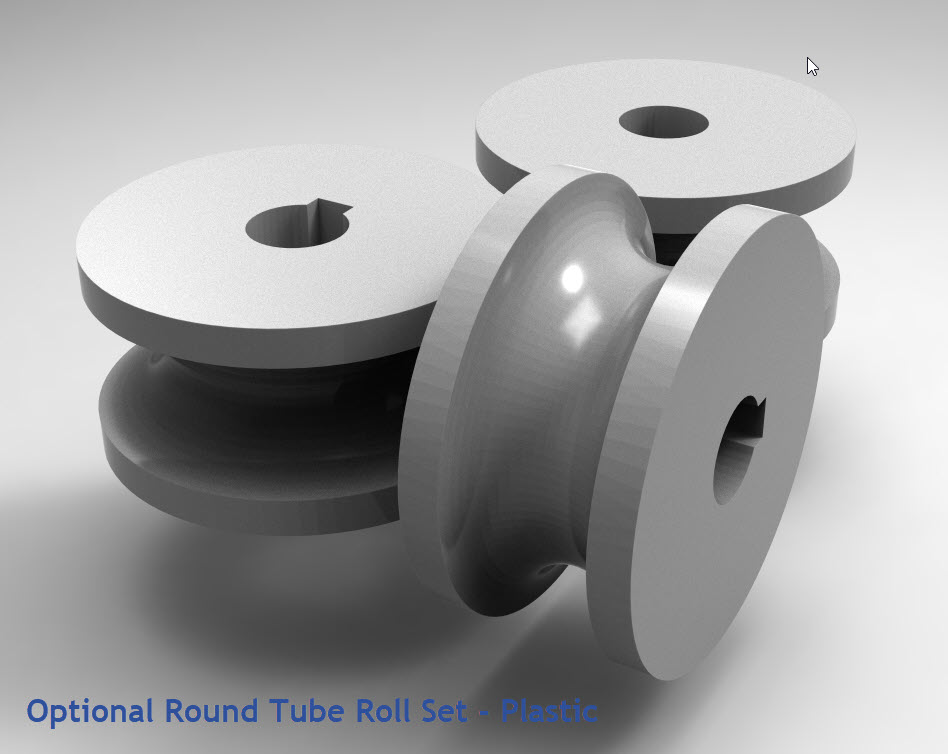

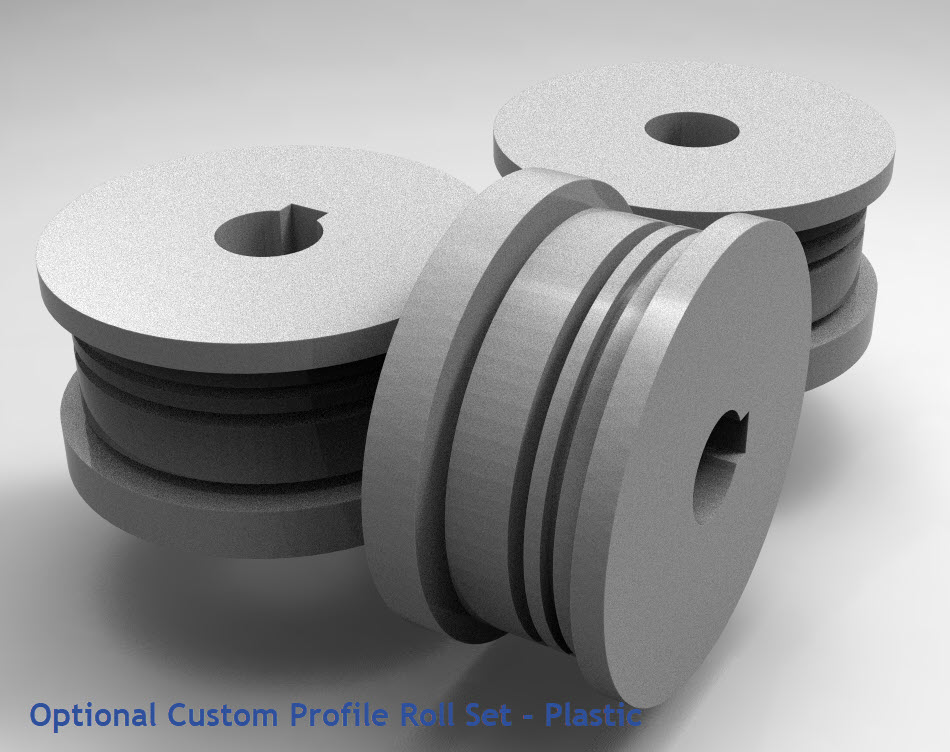

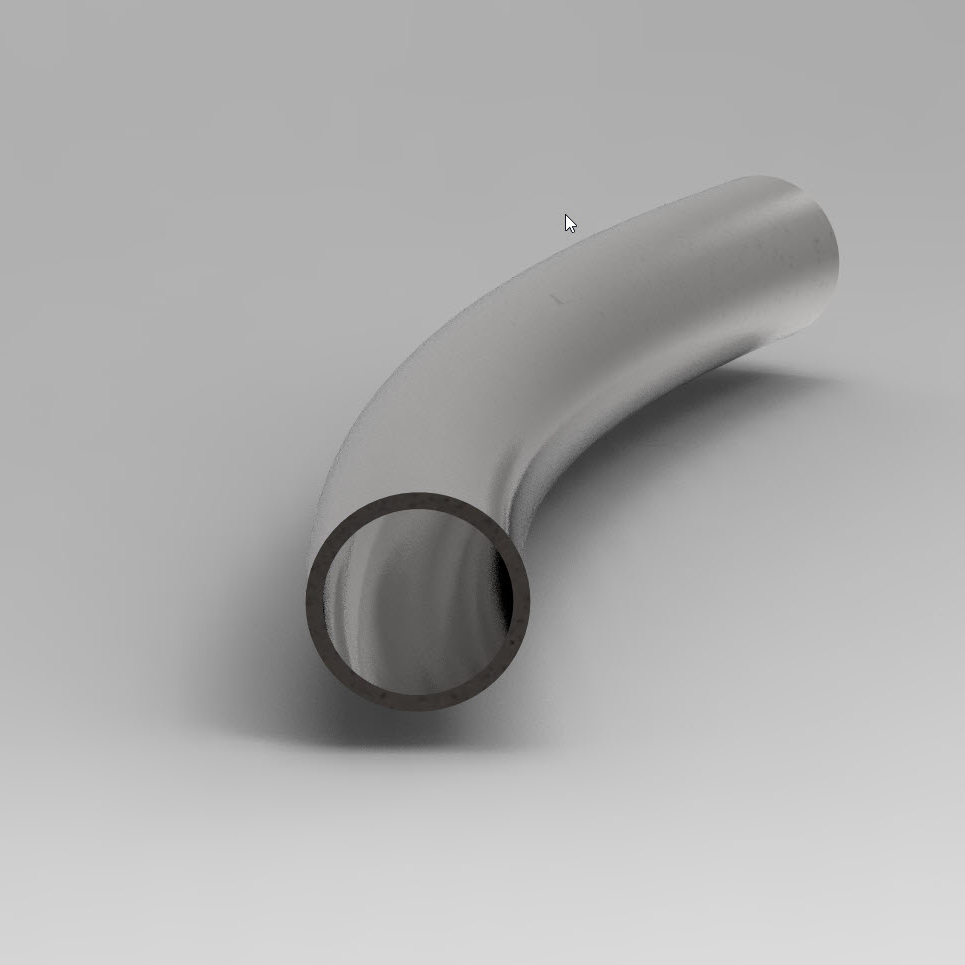

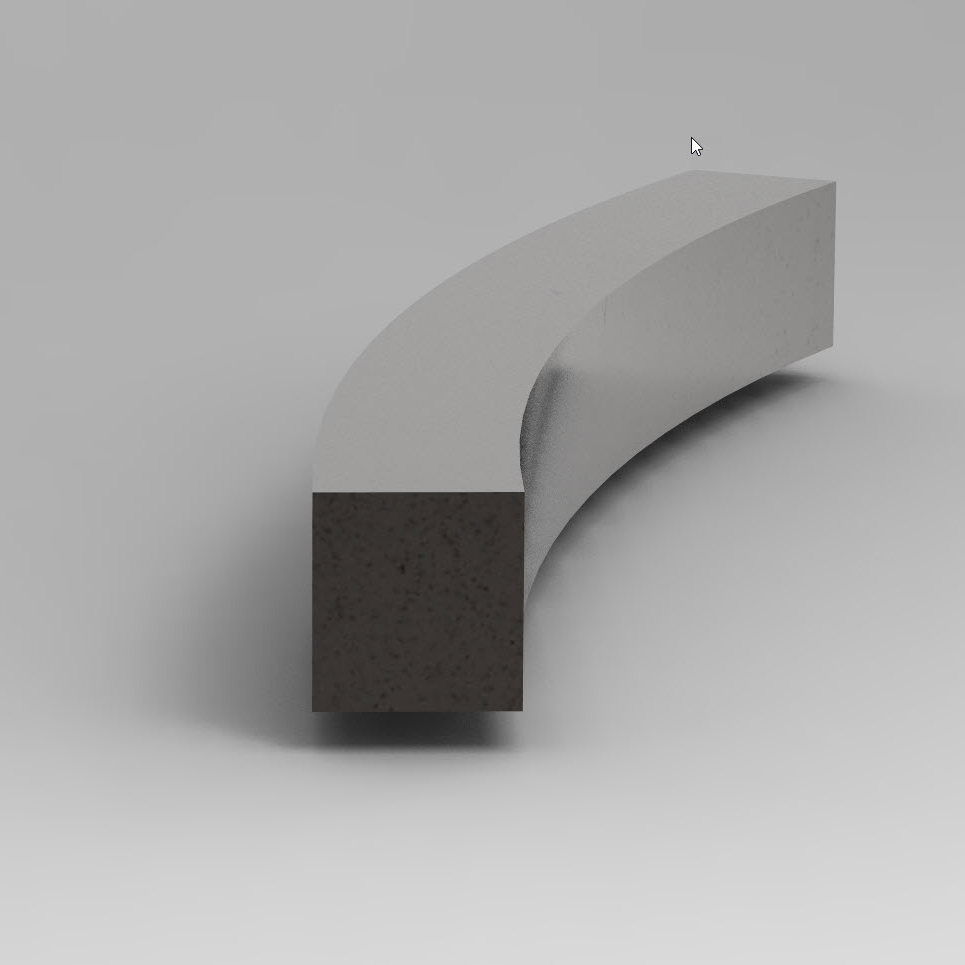

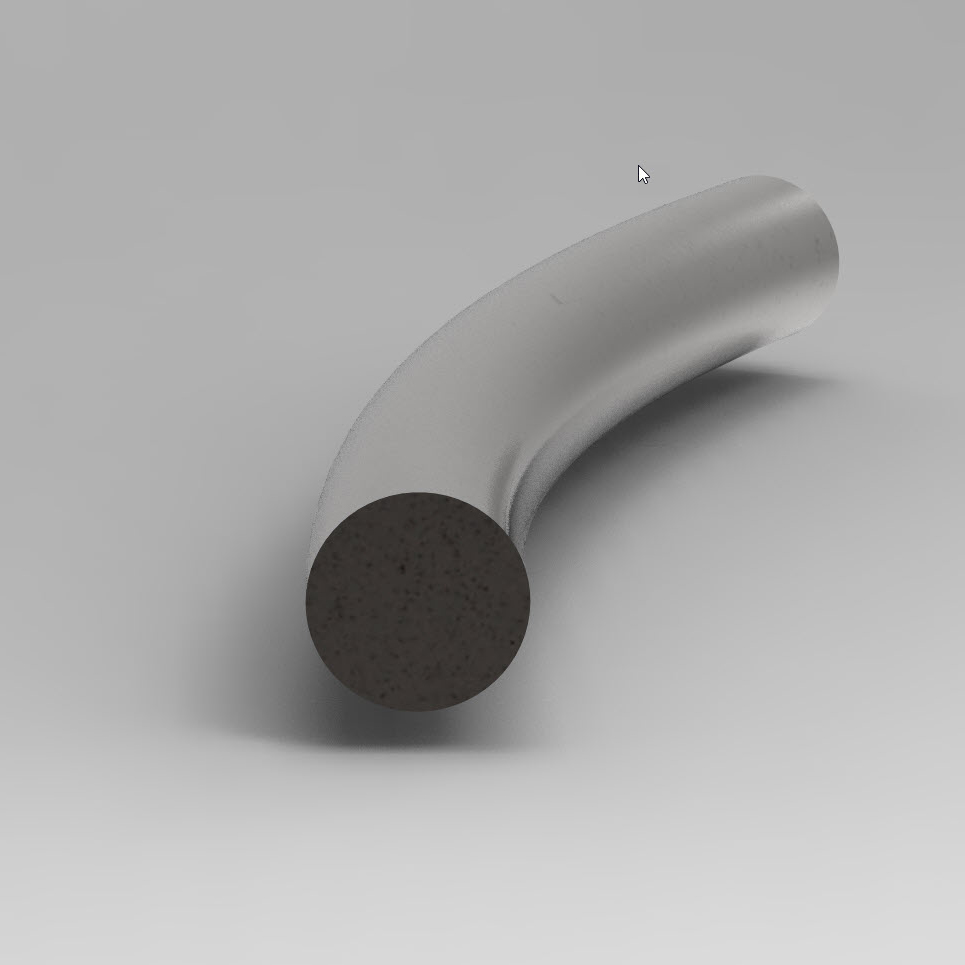

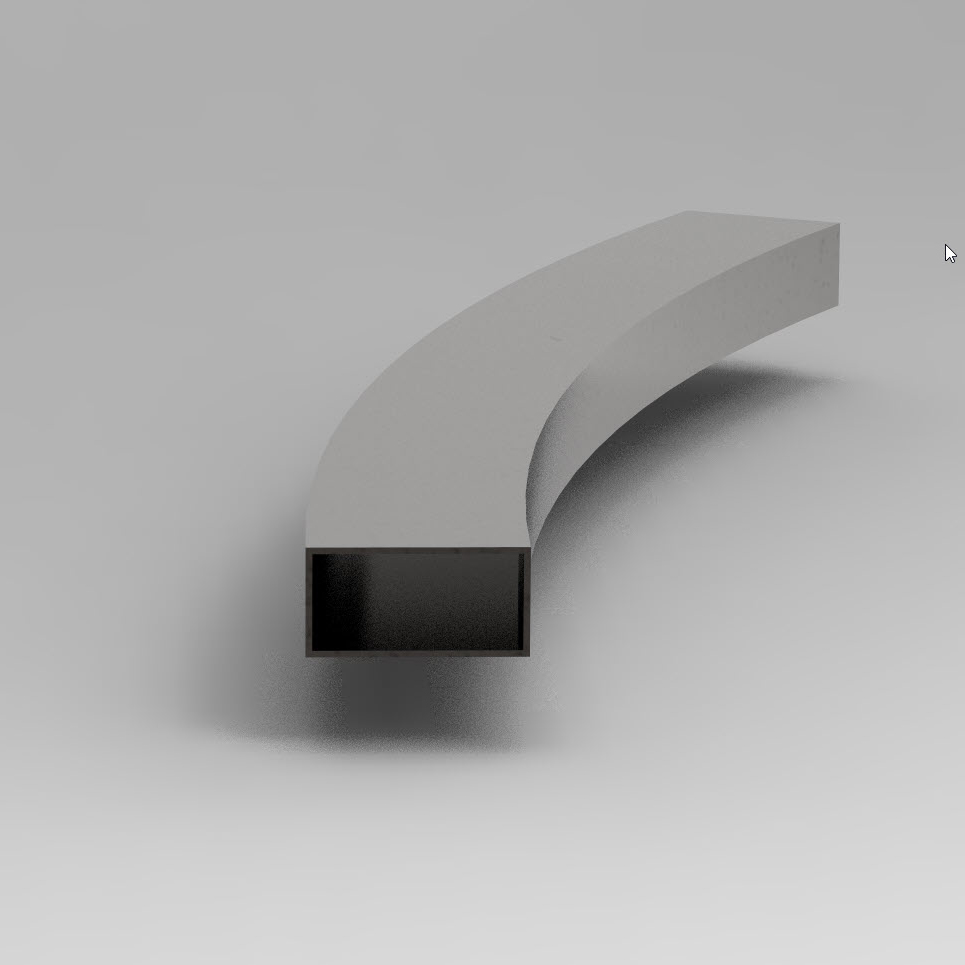

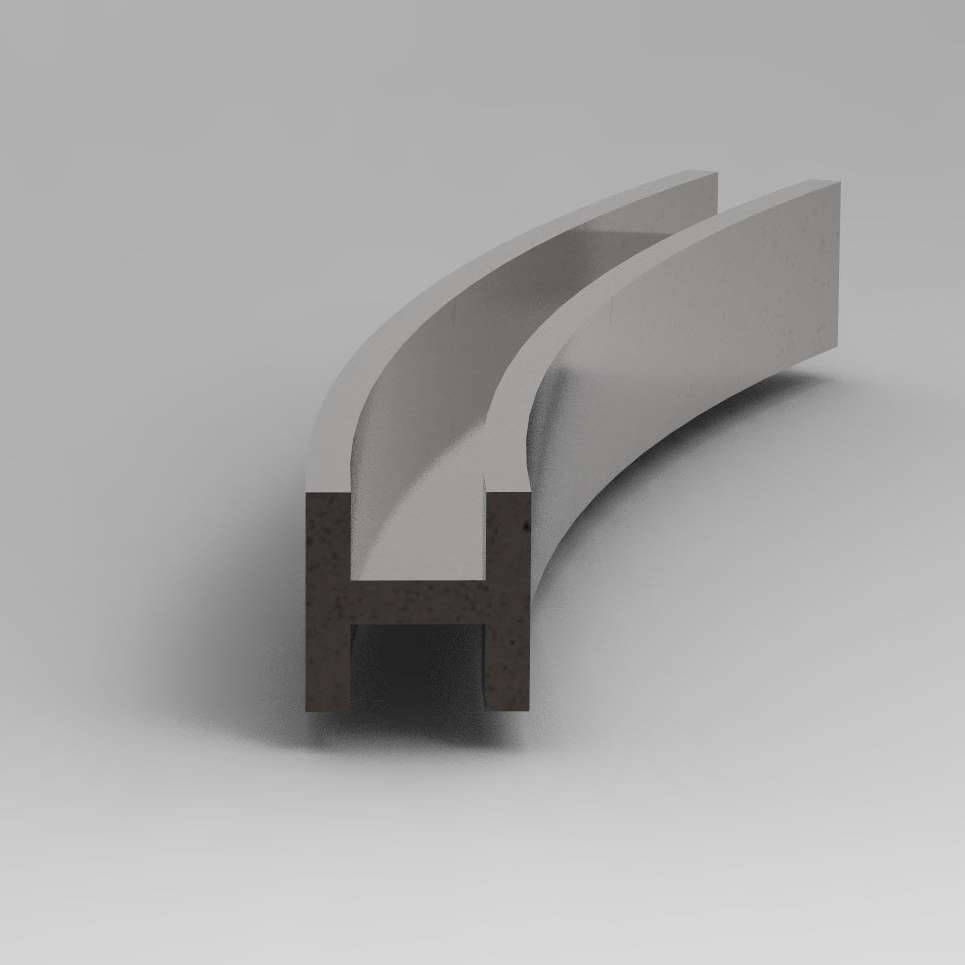

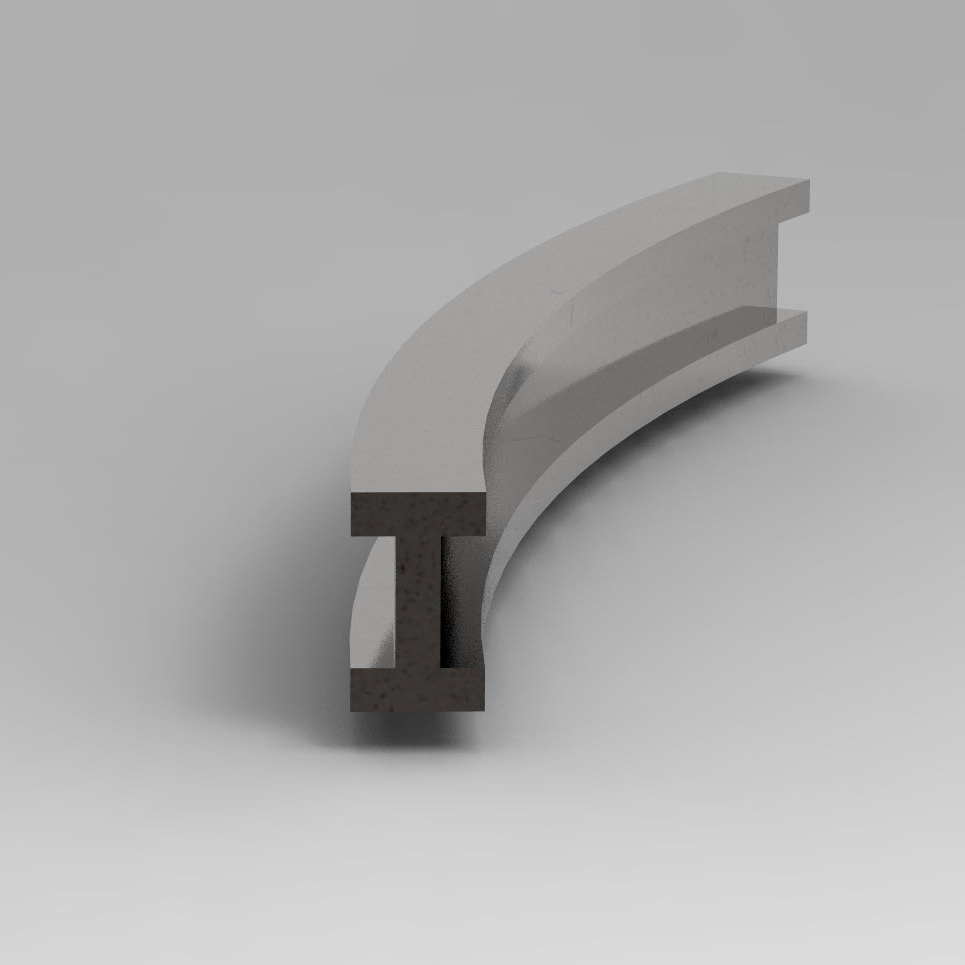

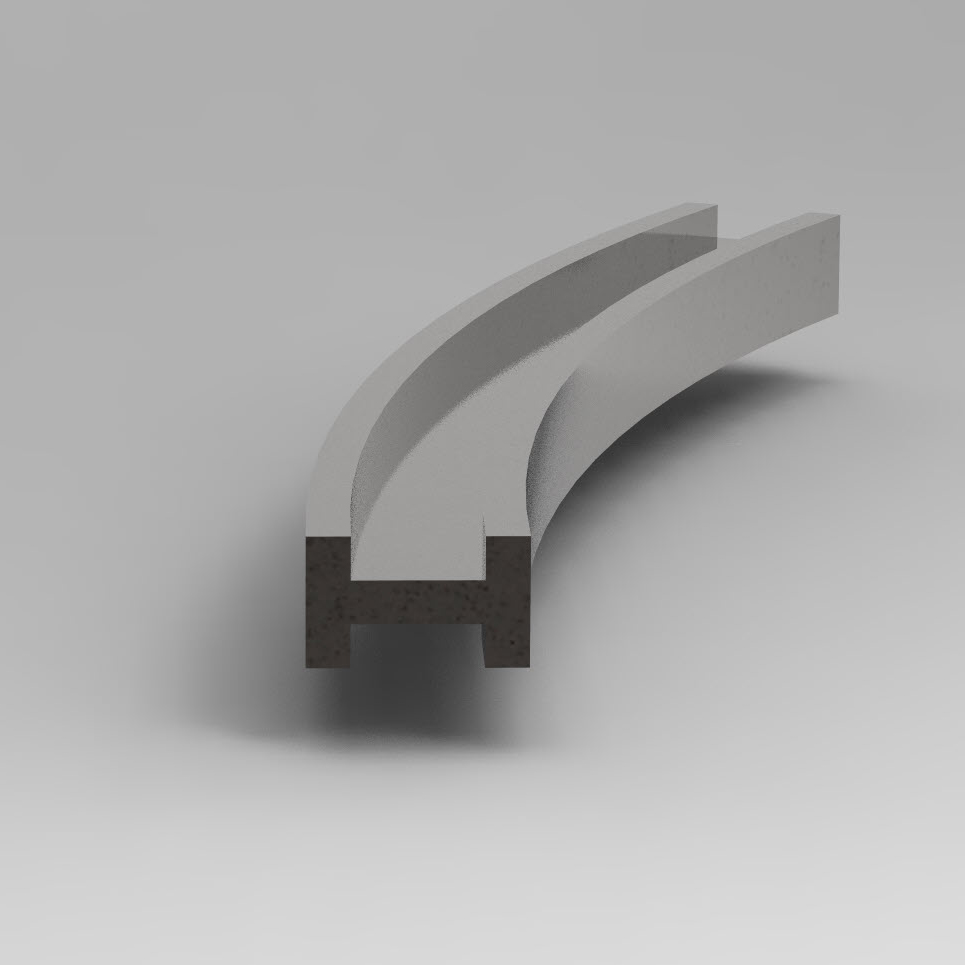

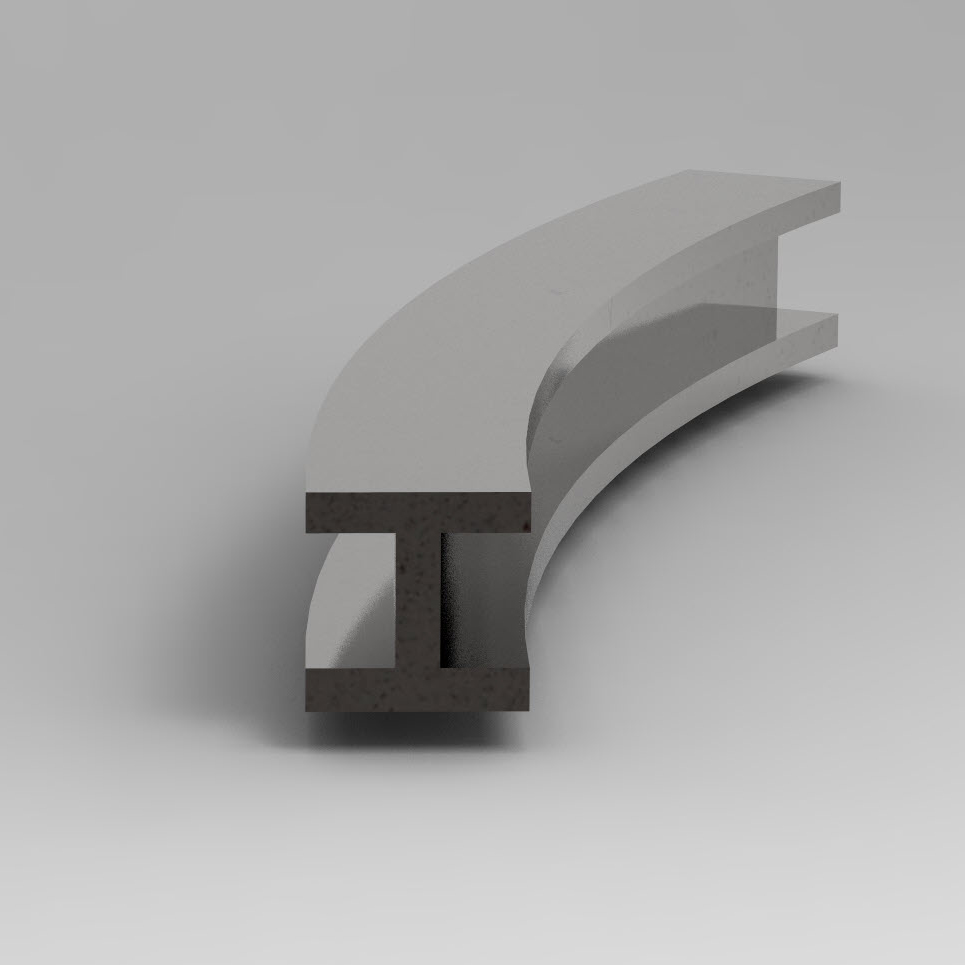

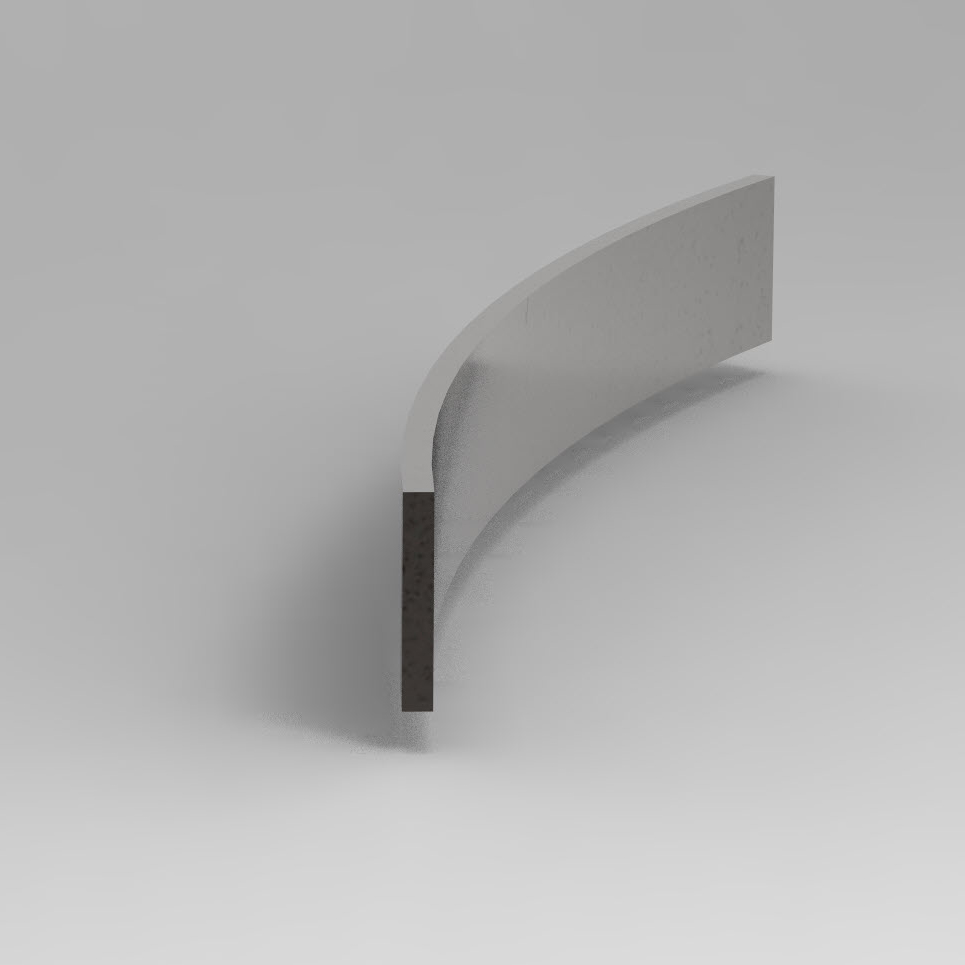

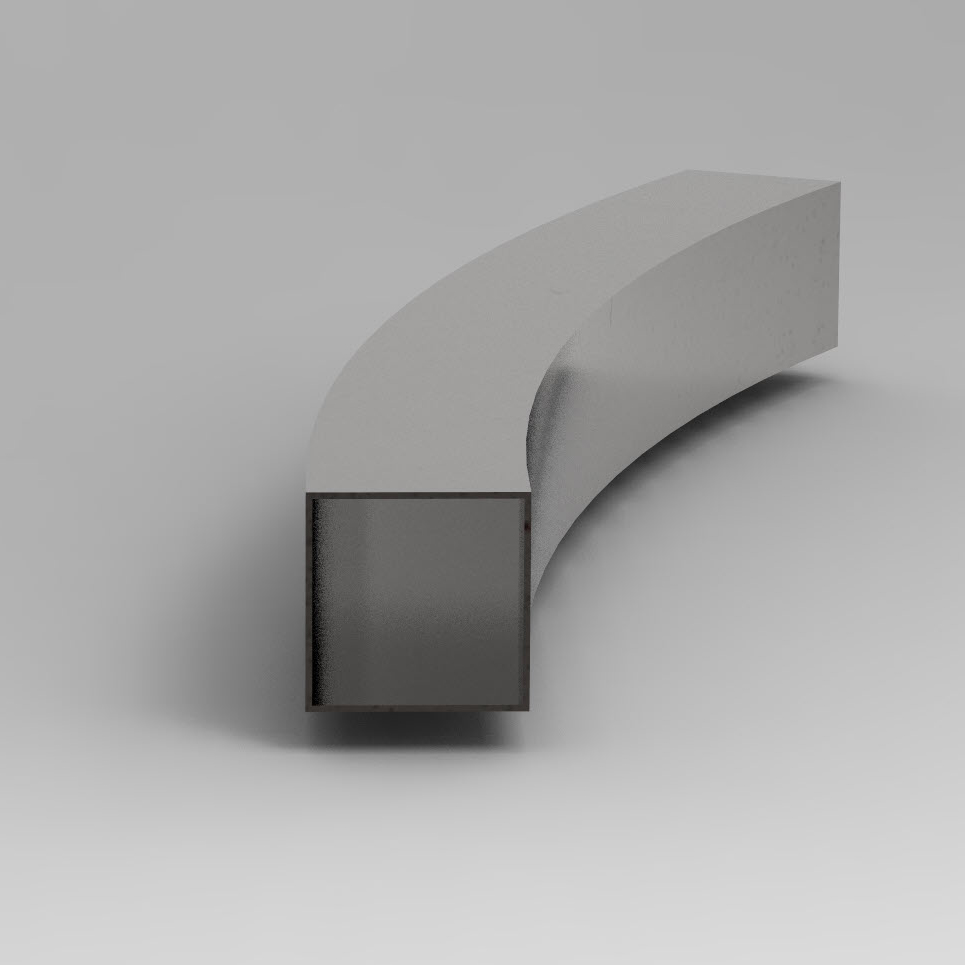

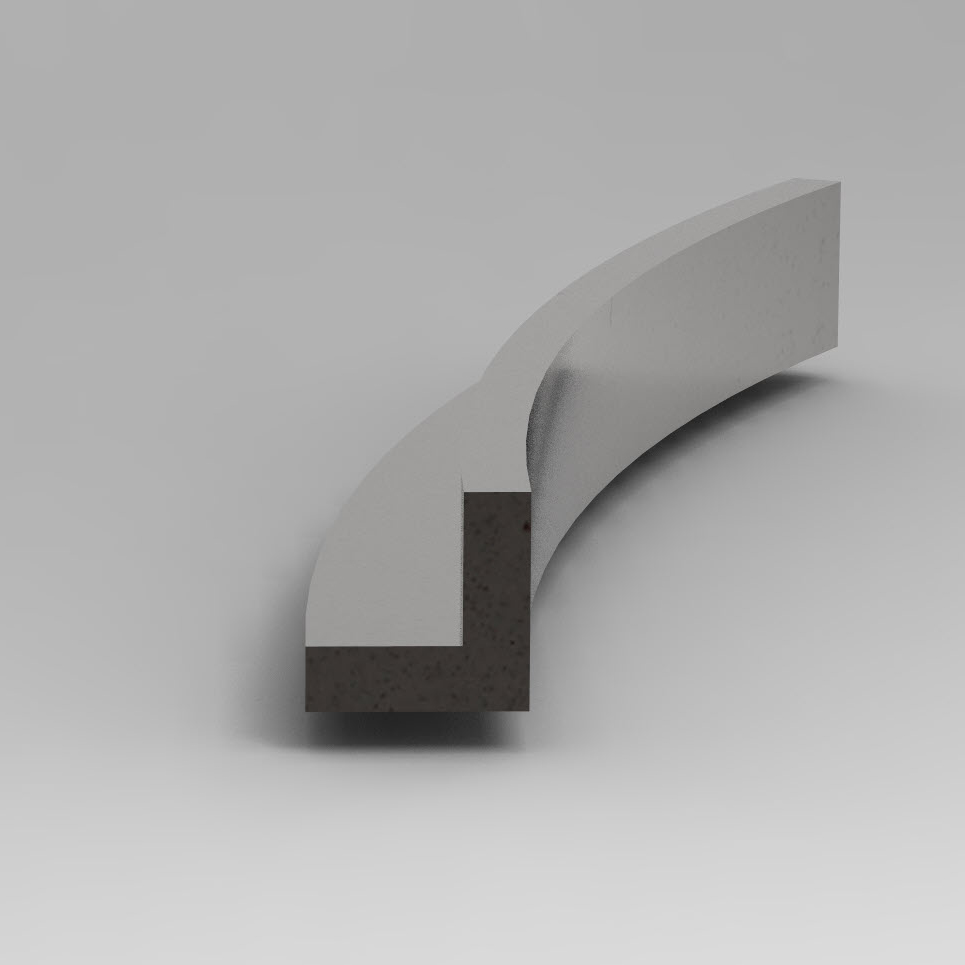

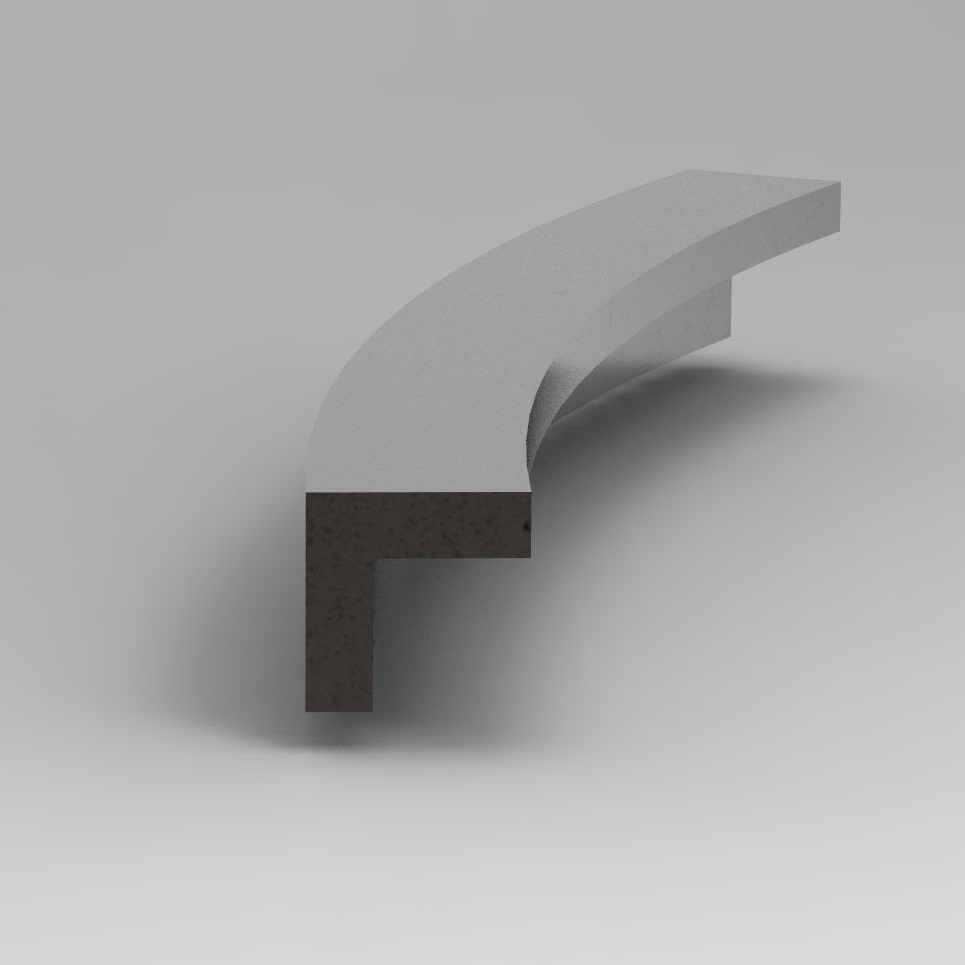

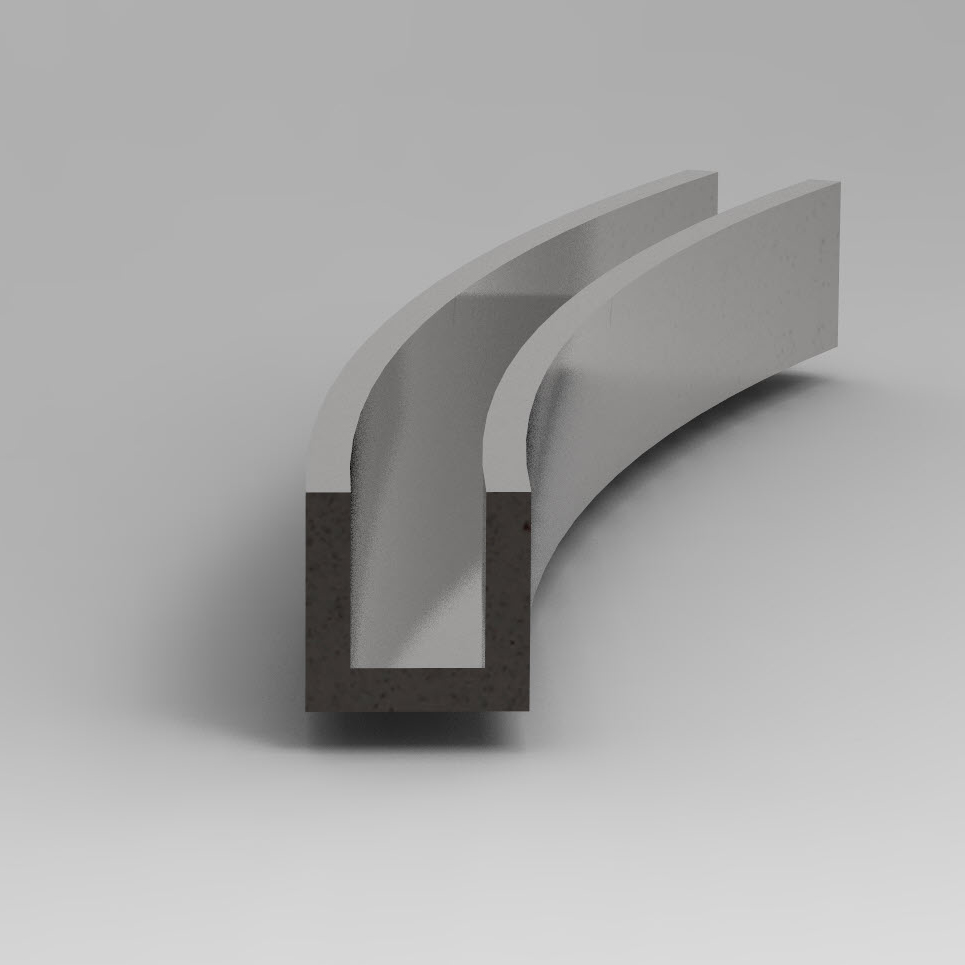

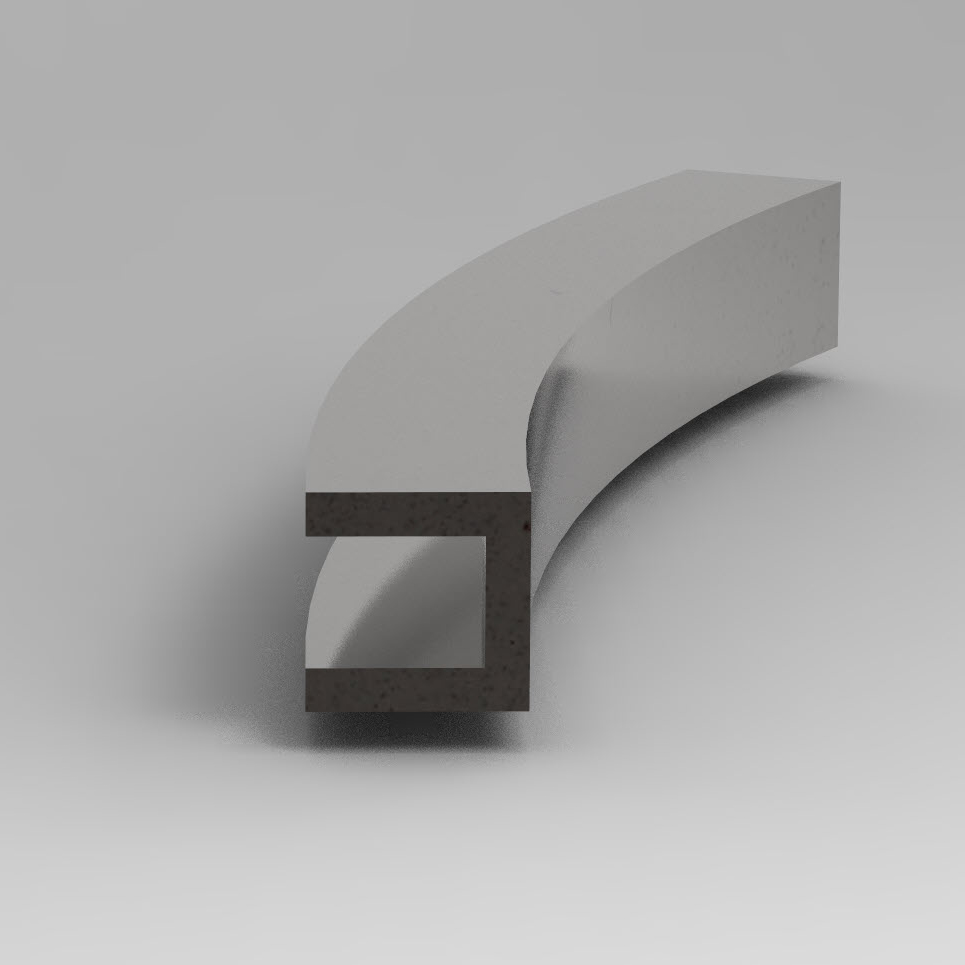

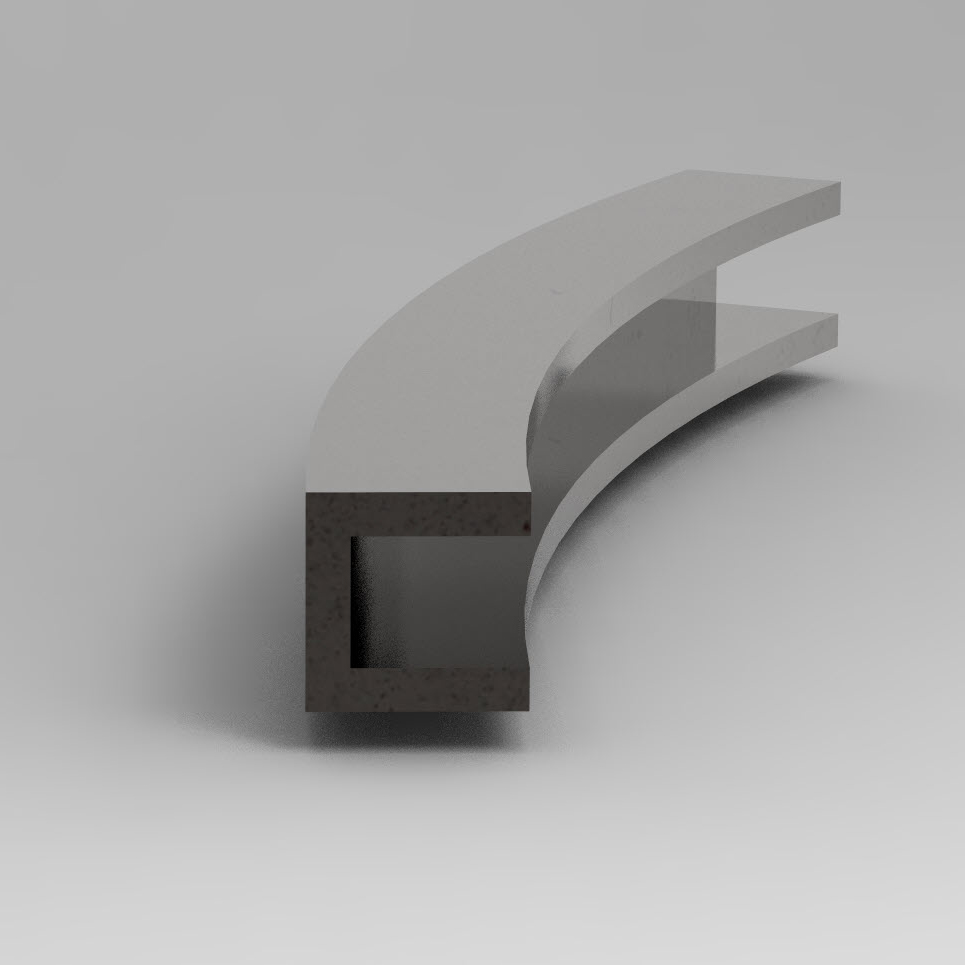

Product Code: PBM-50-2The PBM-50 Profile bender has 50 mm shafts along with 2 driven bottom rolls driven either by a 1-Phase or a 3-Phase motor and comes with a standard set of section rolls that are configurable and are suitable for most bending applications of square or angular profiles. If you wish to bend round tubes or pipe, we have tools ready to go off the shelf for all common sizes such as 42.2 mm and 48.3 mm outside diameters along with many other sizes being readily available. If you are wanting to bend custom profiles all we need from you is either a drawing or a piece of the profile and we can quote your custom rolls.

The top roll is a bearing roll and is adjusted with a ratchet mechanism and the distance is controlled with a scale on the side of the top roll which can produce accurate bends.

The Profile Bender Machine can be flipped 90 degrees backward onto its back pads to make larger and longer bending applications easier in the horizontal plane and the roll speed is controlled with a potentiometer. The direction of the rolls is controlled with an easy to use foot pedal pendant.

One of the most common machines in a manufacturing or fabrication facility is a machine called a Profile Bender. A Profile Bender does exactly what it says, it bends profiles. This type of machine also has many other names that descend directly from the overall versatility of this type of machine. Some common other names include Roll Bender, Profile Roller, Angle Roller, Section Roll, Ring Roller, Ring Bender, Ring Roll Bender, Section Bending Machines, Section Bender,

Please contact for prices

- Description

- Additional Info

Technical Specifications:

Driven Rolls: 2

Roll Adjustment: Manual

Flat Bar Hard Way [mm]: 60 x 10 to Ø900

Flat Bar Easy Way [mm]: 80 x 15 to Ø700

Square Solid Bar [mm]: 35 x 35 to Ø1000

Round Solid Bar [mm]: Ø35 to Ø900

Tube [mm]: Ø60 x 2 to Ø1100

Pipe Nominal Bore [mm]: Ø48.3 x 2.9 to Ø1000

Rectangle Tube [mm]: 50 x 40 x 3

Box Section [mm]: 40 x 40 x 3

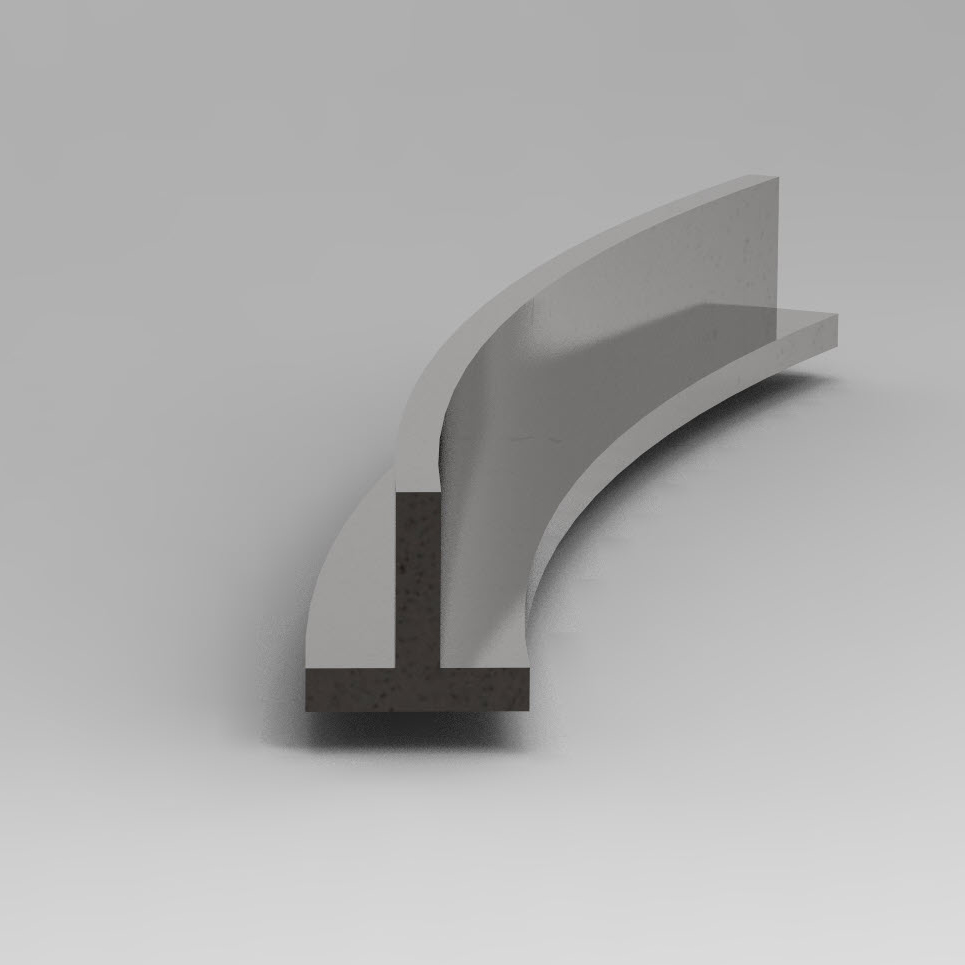

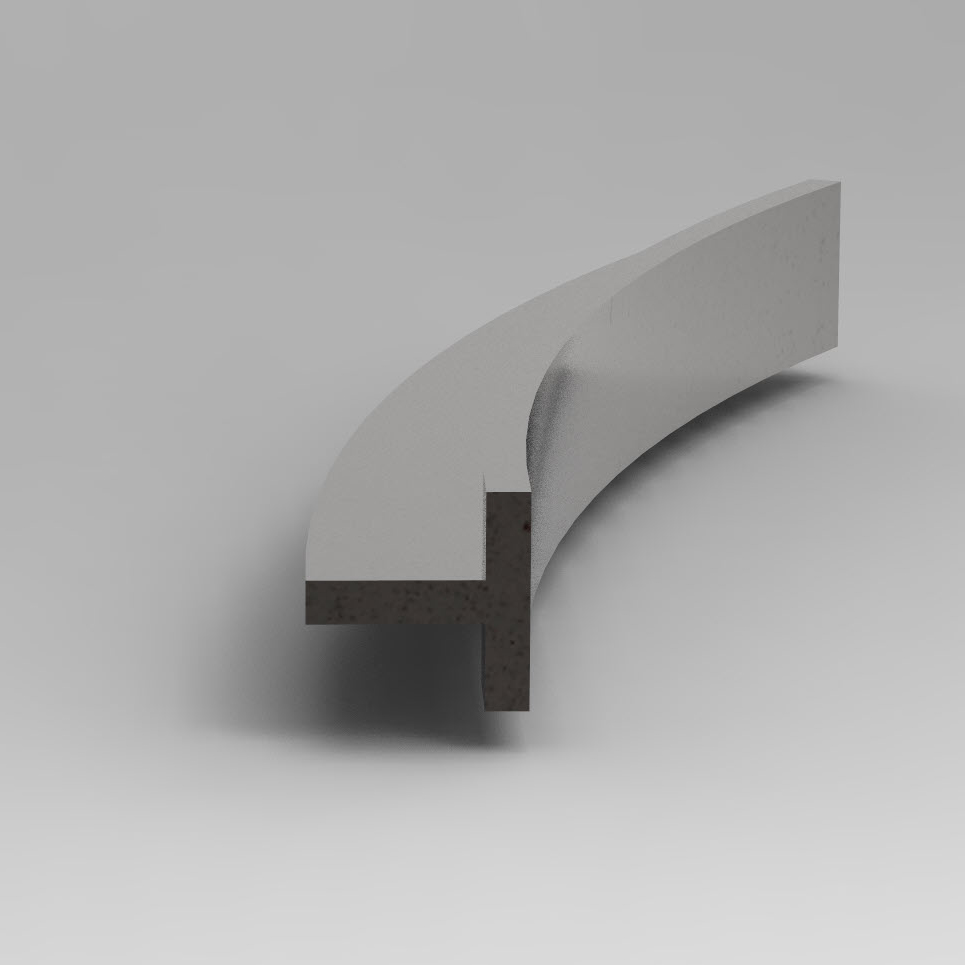

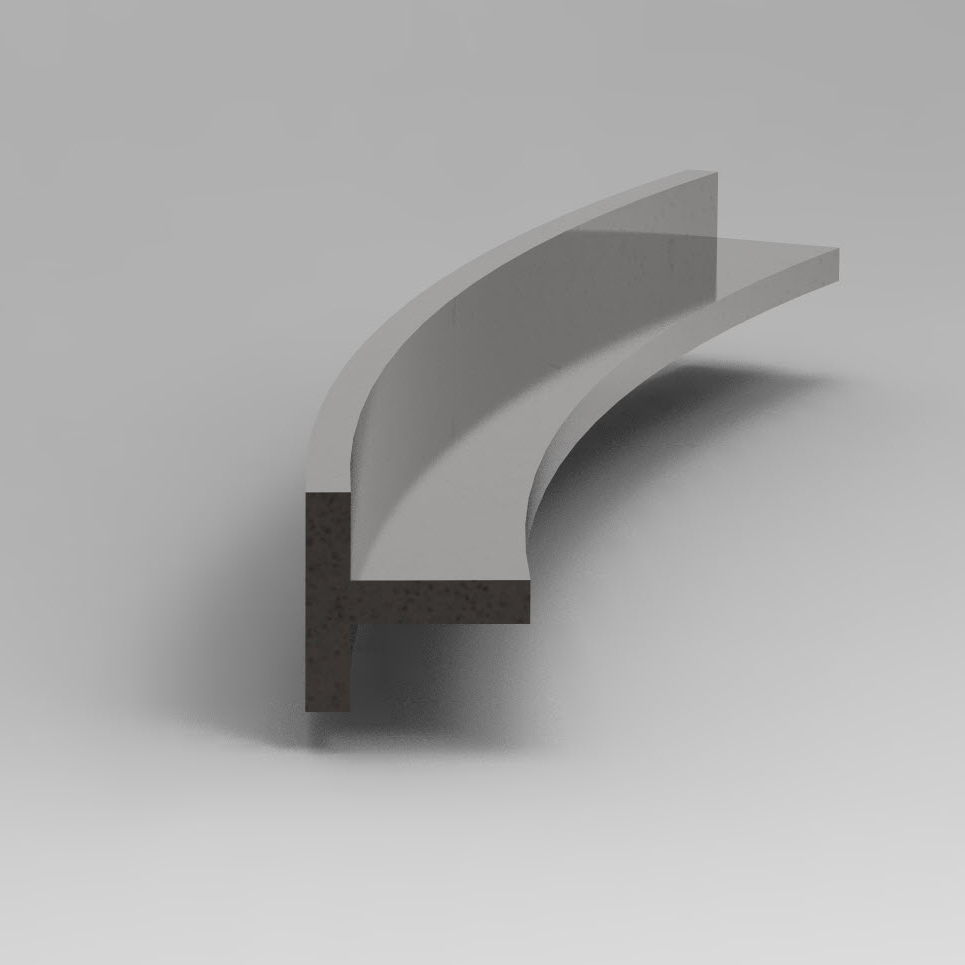

Angle Leg Out [mm]: 50 x 50 x 5 to Ø800

Angle Leg In [mm]: 50 x 50 x 5 to Ø950

T-Section Leg Out [mm]: 50 x 5 to Ø700

T-Section Leg In [mm]: 50 x 5 to Ø900

T-Section Leg Up [mm]: 50 x 5 to Ø900

UNP Section Leg Out [mm]: 60 to Ø900

UNP Section Leg In [mm]: 60 to Ø1300

Shaft Diameter: 50 mm

Motor: 1.5 HP

Power: 220V 1-Ph or 400V 3-Ph, 50 Hz

Shipping Weight: 290 Kg

Specifications: Based on Mild Steel

Shipping Dimensions: 940 x 750 x 1400 mm

PROFILE BENDERS

Profile benders are used to roll out profiles of materials into rings, circles, or sections of a ring or circle and the industries that use profile bending machines are vast and many and some of the uses for ring rollers are to build handrail around buildings, to design metal art, unique components of roll cages for race cars of all types, safety rails and structures around industrial sites and machinery, pulpits on boats, street furniture such as benches and bollards, ships internal and external structures, bridge superstructures, airplane framework, automotive frames, boat and marine framework, and rail transport to name a few.

Ring Rollers come in a wide variety of sizes. From very small machines that are used to make rings for jewellery all the way up to machines that can bend pipes that are 2 metres in diameter with 50mm wall thickness and larger still.

All Profi Benders are manufactured in Europe and are CE Certified and with a 2-Year Warranty and are readily available from our stock.