- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

Press Brake PB-1130 • Hydraulic • 30 Ton • 1100 mm Bending Length • CNC Control • CNC Backgauge

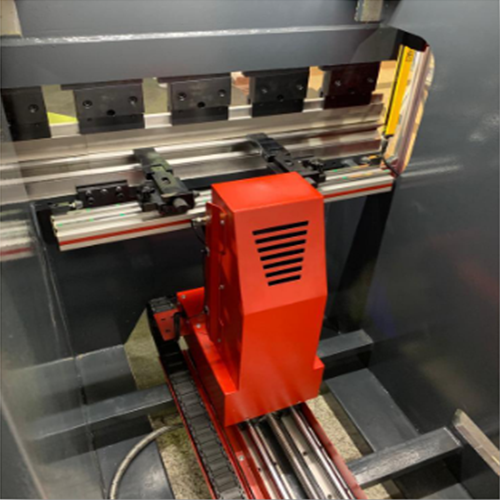

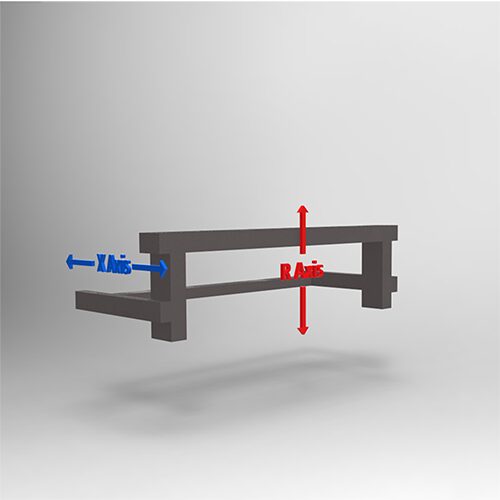

Product Code: PB-1130The PB-1130 CNC Pressbrake has a Bending Force of 30 Tons with an overall Bending Length of 1100 mm. The Beam's stroke is 220 mm and when at the top dead position has a Vertical Daylight of 440 mm and Throat Depth of 250 mm. Movements are high speed with the Approach Speed being 185 mm per second, Bending Speed is 10 mm per second, and the Return Speed is 180 mm per second. There is a standard Back Gauge that is CNC controlled in the X-Axis that has travel of 400 mm which also defines the Z-Axes. There is also manually controlled R Axis that has travel of 200 mm. The motor is 5 kW and can be powered by 220 or 400V power. Both 50 Hz and 60 Hz Models are available. Overall machine dimensions consist of the Length(L) being 2100 mm, Width(W) being 1420 mm, and Height(H) being 2650 mm. The Weight of the machine is 2750 Kg.

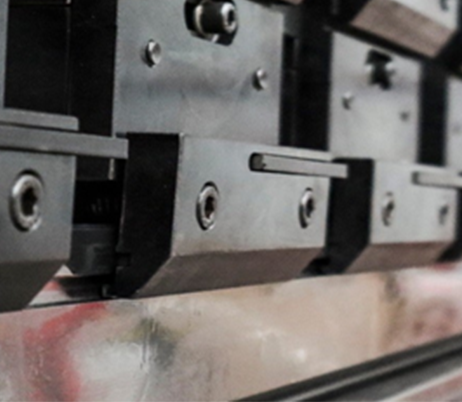

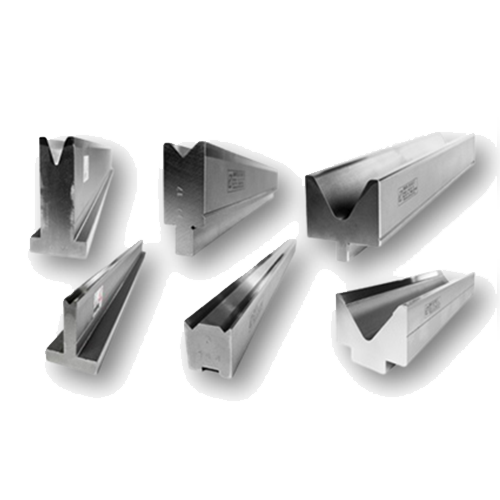

The PB-1130 features a CNC Control Unit Cybelec Cybtouch 8, Euro Top Tool Clamping System, Light Curtain Laser Safety System with Safety PLC, Standard Back Gauge with Servo Motorized & Ball screw System, Back Gauge profile Double Guide Fingers, Control Arms, Led Illumination, Sliding Front Arms, Side Safety Covers, Top Tool European Punch Tool with a working height of 67.6 mm, α=75°, a Radius 0.8 mm, and a Bottom European Type Multi-Vee Tool with a Height of 60 mm and α=85°. Both tools are made from C45 Material and are designed for a max load of 800 kN per square meter.

Please contact for prices

- Description

- Additional Info

Specifications

- Bending Force: 30 Tons

- Bending Length: 1100 mm

- Stroke: 220 mm

- Daylight: 440 mm

- Throat Depth: 250 mm

- Approach Speed: 185 mm / sec

- Bending Speed: 10 mm / sec

- Return Speed: 180 mm / sec

- European Clamping system Standard

- Back gauge : AC Motor & Ballscrew System -Standard

- Back Gauge fingers – Height Adjustable -Standard

- Safety Covers – Standard

- Axes Y1 & Y2

- Axis X 400 mm

- Top Tool – European Style Punch with a working height of 67.6 mm, α=75°, a Radius 0.8mm

- Bottom Tool – European Type Multi-Vee Tool with a Height of 60 mm and α=85°

- STEP RK 12+ – Standard

- Backgauge – R Axis Travel: 200 mm

- Crowning – Manual N/A

- Motor: 5 kW

- Length: 2100 mm

- Width: 1420 mm

- Height: 2650 mm

- Weight: 2750 kg

Options

- Safety Laser Kit MSD 1 point laser

- MCS+DSP AP Laser Kit (PLC included) 5 points laser

- CybTouch 12 Inch 2D Colour Graphic

- CybTouch 15 Inch 2D Colour Graphic

- Crowning – Manual

- Crowning – CNC

- X Axis Servo Motor Drive / PLC upgrade

- R Axis X=400mm X,R Servo Motor Drive / PLC upgrade

- Top Tool European P97.75.R08

- Bottom Tool European M.460R.85

- Quick Release Clamping

- Finger Blocks (Std.) Add. (each one)

- Sliding Front Arm

- Oil Coolant

- Oil Heater

- Control Arm

- Working Table

- LED Illumination

- Mobile Foot Pedal

- Dual Voltage 220/460V

***If there is an optional feature that you need and do not see, please enquire.

The very powerful and easy Cybelec CybTouch PS CNC Control Unit is designed specifically for synchronized press-brakes. As with the entire CybTouch numerical control range, CybTouch PS features simple pages and an intuitive and vivid touch screen user interface seamlessly integrating all critical press brake functions. Large keys make the user-friendly software even easier to use while enhancing the rich offering of automatic functions that constantly guide the operator. Simply put, CybTouch PS is as powerful as it is easy to use. There is and easy single bend page and integrated online help and warning pop-ups. The housing for the CybTouch PS is a sleek and modern housing specially designed to enhance ergonomics and is attached to a swiveling arm. Bespoke cabinetry for the CybTouch PS to suit the customers application is also available so please enquire.

The Karbend Pressbrakes are equipped with an X-Axis 400mm CNC back gauge constructed with a solid structure assuring repetitiveness, accuracy, and high precision in axes positioning. The X-Axis is runs on an top brand linear guide and Ball Screw and the standard back gauge system has both manual R-Axis and Z-Axis with quality double linear guides and a heavy-duty aluminum sigma profile meaning there is less noise generated alongside greater durability precision with repeatability of ±0.005mm. And movements are high speed.

The top beam has a Euro Type Top Clamping System & Advantages which makes the changeover process easy, quick, and safe. The bottom Slotted Bottom Die Holder is Euro/American suitable for a common 4v die with 60 mm housing. Our system offers fast and durable tool changover, easy tool alignment, and comes with a standard manual crowning systems. CNC Crowning systems are also available.