- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

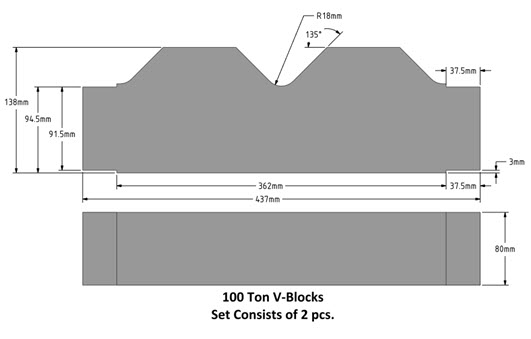

V-Block Set • Designed for 100 Ton Workshop Presses • Suits Other Presses • Mutli-Purpose

Product Code: PP100008-V-BLOCK-100TDesigned for precision and durability our 100 Ton V-Block Set, meticulously engineered from high-grade steel with a super-high tensile strength. They are coated with anti-corrosive material for enhanced longevity, these V-Blocks are specifically designed to integrate seamlessly with 100 Ton hydraulic presses. Measuring 300 mm in length, 100 mm in width, and 150 mm in height, they are suitable for handling both flat and cylindrical workpieces. Safety is paramount; the V-Blocks feature a machined anti-slip recess on both ends for secure workpiece placement, along with an even load distribution design to minimize workpiece deformation. Bespoke sizes and designs can be manufactured upon request. Ideal for metal fabrication, automotive repairs, and a myriad of industrial applications, our 100 Ton V-Blocks offer multi-directional utility and customizable features tailored to your specific needs.

Please contact for prices

- Description

- Additional Info

V-Blocks are indispensable tools in Motorized Workshop Presses and other presses and are appropriate for a variety of applications that require precision and stability.

Here are some specific uses:

Shaft Straightening:

V-Blocks can hold cylindrical shafts securely for straightening operations, ensuring that the applied force is evenly distributed.

Bushing and Bearing Installation:

They are ideal for holding components like bushings and bearings in place while they are being fitted onto shafts or housings.

Material Testing:

V-Blocks can be used to hold test specimens of metals or other materials while applying compressive or tensile forces to gauge material properties.

Drilling and Milling Support:

When used in conjunction with a drill press attachment, V-Blocks can hold the workpiece securely for precise drilling or milling.

Tube and Pipe Bending:

V-Blocks with specialized grooves can be used for secure placement of tubes and pipes during bending operations.

Metal Stamping and Forming:

They can hold sheet metal or other flat materials securely in place during stamping or forming processes.

Gear and Sprocket Alignment:

V-Blocks can be used to hold gears and sprockets in the correct orientation for alignment checks or modifications.

Welding and Fabrication:

They can hold parts in the optimal position for welding, ensuring that the components are aligned correctly.

Assembly Operations:

In assembly lines, V-Blocks can hold various parts in the correct orientation for efficient and accurate assembly.

Quality Control and Inspection:

They can hold components securely for dimensional checks, ensuring that parts meet quality standards.

Each of these applications benefits from the V-Block’s ability to securely hold workpieces, distribute applied forces evenly, and enhance operator safety. Would you like more information on any of these specific uses?

V-Blocks are versatile tools in motorized workshop presses, serving a multitude of applications that demand precision and stability. They are essential for shaft straightening, ensuring even force distribution across cylindrical shafts. In the realm of bushing and bearing installation, V-Blocks hold these components securely in place while being fitted onto shafts or housings. They also play a crucial role in material testing, holding test specimens securely for compressive or tensile force applications. Our Steel V-Blocks can be used on other machines such as a pillar drill press where they provide a stable base for precise drilling and milling operations. Specialized V-Blocks are used for tube and pipe bending, ensuring accurate and consistent bends. They are also invaluable for some metal stamping and forming operatinos where they holding sheet metal secure during these processes. For gear and sprocket alignment, V-Blocks hold these components in the correct orientation, and they are equally useful in welding and fabrication for aligning parts correctly. In assembly lines, they facilitate efficient and accurate assembly by holding various parts in the correct orientation. Lastly, they are indispensable in quality control and inspection, holding components securely for dimensional checks to meet quality standards.