- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

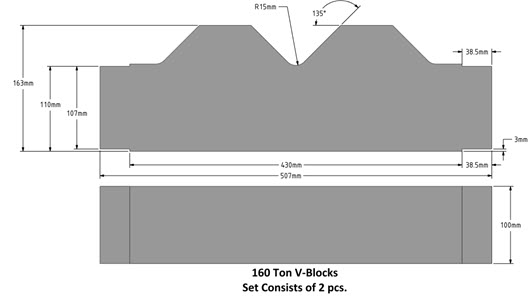

V-Block Set • Designed for 160 Ton Workshop Presses • Suits Other Presses • Mutli-Purpose

Product Code: PP100009-V-BLOCK-160TEngineered for accuracy and long-lasting performance, our 160 Ton V-Block Set is crafted from premium-grade steel boasting exceptional tensile strength. Treated with a corrosion-resistant coating to extend lifespan, these V-Blocks are purpose-built to align flawlessly with 100 Ton hydraulic presses. With dimensions of 380 mm in length, 125 mm in width, and 200 mm in height, they are versatile enough to accommodate both flat and rounded workpieces. Prioritizing safety, each V-Block comes with precision-machined anti-slip recesses at both ends, ensuring stable workpiece positioning and uniform force distribution to reduce deformation risks. Custom dimensions and configurations are available upon inquiry. Perfectly suited for tasks in metalworking, automotive maintenance, and various industrial settings, our 160 Ton V-Blocks provide versatile functionality and adaptability to meet your specific requirements.

Please contact for prices

- Description

- Additional Info

V-Blocks are essential accessories in Motorized Workshop Presses and various hydraulic press systems, suitable for an array of tasks demanding both accuracy and stability.

Specific Applications of 160 Ton V-Blocks in Hydraulic Workshop Presses:

• Shaft Alignment:

V-Blocks are adept at securely gripping hefty cylindrical shafts for alignment procedures, guaranteeing uniform force application.

• Installation of Bearings and Bushings:

These blocks excel in stabilizing components such as bearings and bushings during their installation onto larger shafts or casings.

• Mechanical Property Testing:

Utilize larger V-Blocks to securely hold bulkier test samples for applying compressive or tensile forces to evaluate material characteristics.

• Support for Drilling and Milling:

When paired with specialized drill press attachments, these V-Blocks offer a stable platform for accurate drilling or milling tasks.

• Bending of Large Tubes and Pipes:

V-Blocks grooves are ideal for the secure positioning of larger tubes and pipes during complex bending processes.

• Forming and Stamping of Metal:

These blocks can firmly grip larger sheets of metal or other planar materials during stamping or forming activities.

• Alignment of Large Gears and Sprockets:

V-Blocks are perfect for maintaining the correct orientation of sizable gears and sprockets during alignment adjustments.

• Fabrication and Welding:

They provide an optimal base for holding larger components in the right position for precise welding tasks.

• Assembly Line Operations:

In industrial assembly settings, these V-Blocks are invaluable for holding a variety of larger components in the correct alignment for efficient and precise assembly.

• Inspection and Quality Assurance:

V-Blocks are crucial for securely holding components during dimensional assessments, ensuring compliance with quality benchmarks.

Summary:

Each of these specialized tasks gains from the larger V-Block’s enhanced capacity to firmly grip workpieces, uniformly distribute applied forces, and bolster operator safety.

V-Blocks serve as multifaceted instruments for use with Motorized Workshop Presses and other Metal Fabrication Machinery, catering to a wide range of tasks requiring both accuracy and stability. They are indispensable for aligning shafts, guaranteeing uniform application of force on cylindrical components. When it comes to installing bushings and bearings, V-Blocks offer a secure grip, ensuring precise fitting onto shafts or casings. They are also pivotal in evaluating material properties, firmly holding test samples for compressive or tensile testing. In conjunction with a pillar drill press, V-Blocks offer a reliable foundation for exact drilling and milling tasks. Custom-designed V-Blocks are employed for bending tubes and pipes with high precision. They prove to be crucial in metalworking activities like stamping and forming, offering a secure hold on sheet metal. For aligning gears and sprockets, V-Blocks maintain the components in the proper alignment. They are equally effective in welding and fabrication tasks, ensuring correct part alignment. In production lines, V-Blocks contribute to streamlined and precise assembly by maintaining the correct positioning of various components. Finally, they are essential in quality assurance procedures, securely holding items for dimensional verification to uphold quality benchmarks.