- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

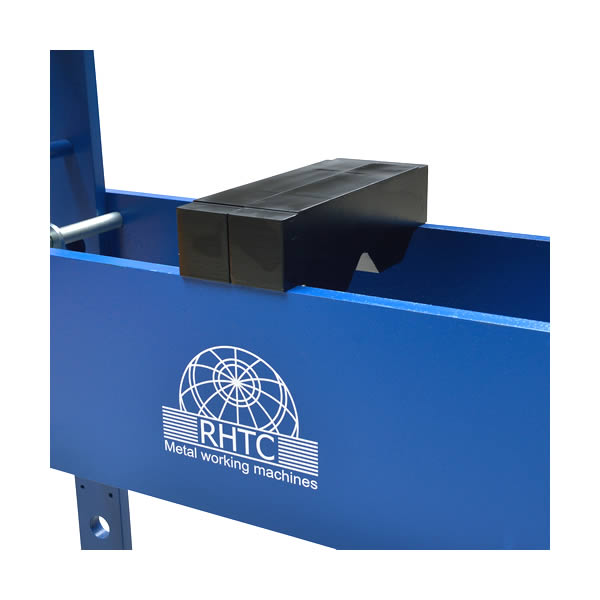

V-Block Set • Designed for 300 Ton Workshop Presses • Suits Other Presses • Mutli-Purpose

Product Code: PP100011-V-BLOCK-300TCrafted for unparalleled precision and lasting durability, our 300 Ton V-Block Set is made from premium-grade steel, exhibiting extraordinary tensile strength. Treated with a corrosion-resistant finish to ensure longevity, these V-Blocks are precisely designed to be fully compatible with 300 Ton hydraulic presses. With dimensions of 500 mm in length, 200 mm in width, and 300 mm in height, they are versatile enough to accommodate a wide range of workpieces, be they flat or cylindrical. Safety remains a paramount concern; each V-Block features intricately machined anti-slip channels at both ends, ensuring stable workpiece positioning and uniform force distribution to mitigate deformation risks. Custom sizes and configurations are available for specialized requirements. Perfectly tailored for use in metal processing, automotive maintenance, and various industrial sectors, our 300 Ton V-Blocks offer extensive versatility and adaptability to meet your unique specifications.

Please contact for prices

- Description

- Additional Info

Specific Uses of 200 Ton V-Blocks in Hydraulic Workshop Press Systems:

• Cylindrical Shaft Stabilization:

V-Blocks excel in firmly clamping large cylindrical shafts for precise alignment, ensuring even distribution of applied forces.

• Fitting Bearings and Bushings:

These blocks are proficient in anchoring components like bearings and bushings while they are mounted onto expansive shafts or enclosures.

• Material Strength Evaluation:

Employ these larger V-Blocks to securely grasp more substantial test specimens for compressive or tensile strength analysis.

• Drilling and Milling Assistance:

In conjunction with dedicated drill press fixtures, these V-Blocks provide a robust base for high-precision drilling or milling.

• Securing Tubes and Pipes for Bending:

The grooves in these V-Blocks are designed for the stable placement of oversized tubes and pipes during intricate bending operations.

• Metal Forming and Stamping:

These blocks are adept at holding larger metal sheets or other flat materials securely for stamping or forming processes.

• Gear and Sprocket Positioning:

V-Blocks are ideal for keeping large gears and sprockets in the proper alignment for adjustments or modifications.

• Welding and Component Fabrication:

They offer an excellent foundation for positioning larger parts accurately for detailed welding activities.

• Industrial Assembly Efficiency:

In manufacturing assembly lines, these V-Blocks are essential for maintaining the correct orientation of various larger components for streamlined and accurate assembly.

• Quality Control and Measurement:

V-Blocks play a vital role in holding components securely for dimensional verification, ensuring they meet quality standards.

Summary:

Each of these specific applications benefits from the 200 Ton V-Block’s superior ability to securely hold workpieces, evenly distribute forces, and enhance the safety of the operator.

V-Blocks for Industrial Motorised Workshop Presses are multifunctional tools also used with other Metal Fabrication Systems, catering to a wide array of operations that require both precision and dependability. They are instrumental in the precise calibration of shafts, guaranteeing even force application on cylindrical elements. When it comes to affixing bushings and bearings, V-Blocks offer a secure clamping mechanism, ensuring exact insertion into shafts or housings. They take on a significant role in material assessment, firmly gripping test specimens for compressive or tensile testing. In conjunction with a benchtop drill press, V-Blocks provide a solid platform for high-accuracy drilling and milling activities. Custom-engineered V-Blocks are employed for the accurate curvature of tubes and pipes. In metal forming and stamping processes, they deliver a secure hold on sheet metal and other planar substances. For the alignment of gears and sprockets, V-Blocks assist in keeping these parts in the proper orientation. They prove to be essential in welding and fabrication tasks, facilitating accurate part positioning. In manufacturing assembly processes, V-Blocks contribute to operational efficiency and precision by maintaining the correct alignment of various components. Finally, they are indispensable in quality assurance protocols, securely holding items for dimensional verification to comply with quality criteria.