VH13 Series Multi-Spindle Drill Heads

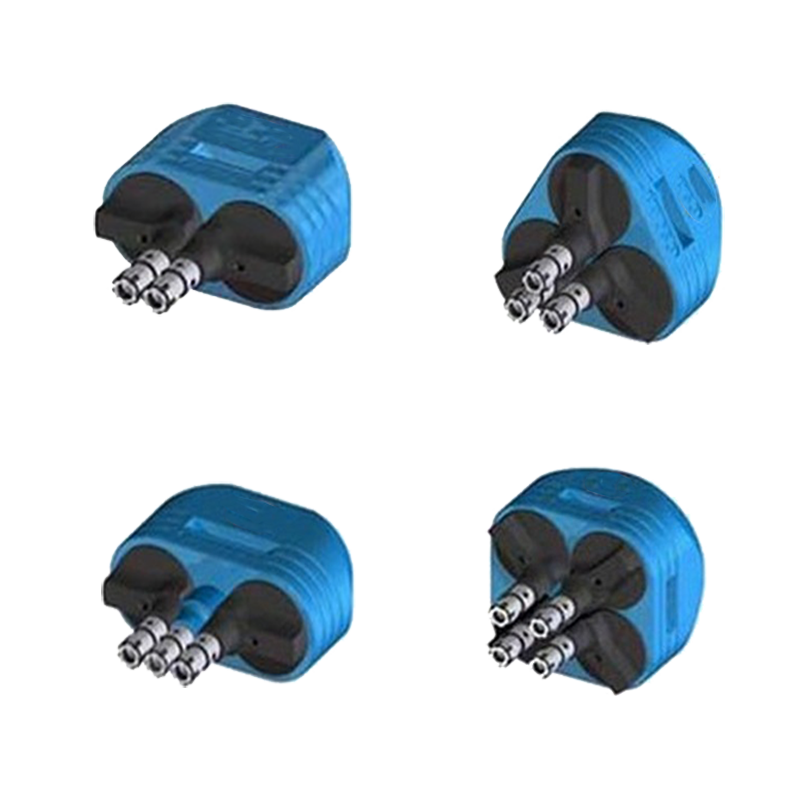

Product Code: VH132 / VH133L / VH133 / VH134The VH13 Series multi-spindle drill heads are designed for large-diameter drilling operations in heavy-duty industrial applications. Equipped with ER25 spindles, these heads handle larger tools and higher torque loads, making them ideal for machining steel, cast iron, and other hard materials. Available in 2–4 spindle configurations, the VH13 Series offers both radial and linear layouts to match complex production requirements.

Please contact for prices

- Description

- Additional Info

The VH13 Series delivers unmatched durability and precision for high-demand drilling environments. Using ER25 spindles, these heads can accommodate tooling up to Ø 16 mm and tap up to M12 in steel. Each model is built with a reinforced housing and precision-ground gearing for synchronized spindle motion, allowing consistent performance at speeds up to 4,000 RPM.

Ideal for CNC machining centers, automated drilling lines, and fixture-mounted production cells, the VH13 Series is available in multiple configurations to cover a wide range of multi-hole patterns in one operation.

VH132 L

VH133 L

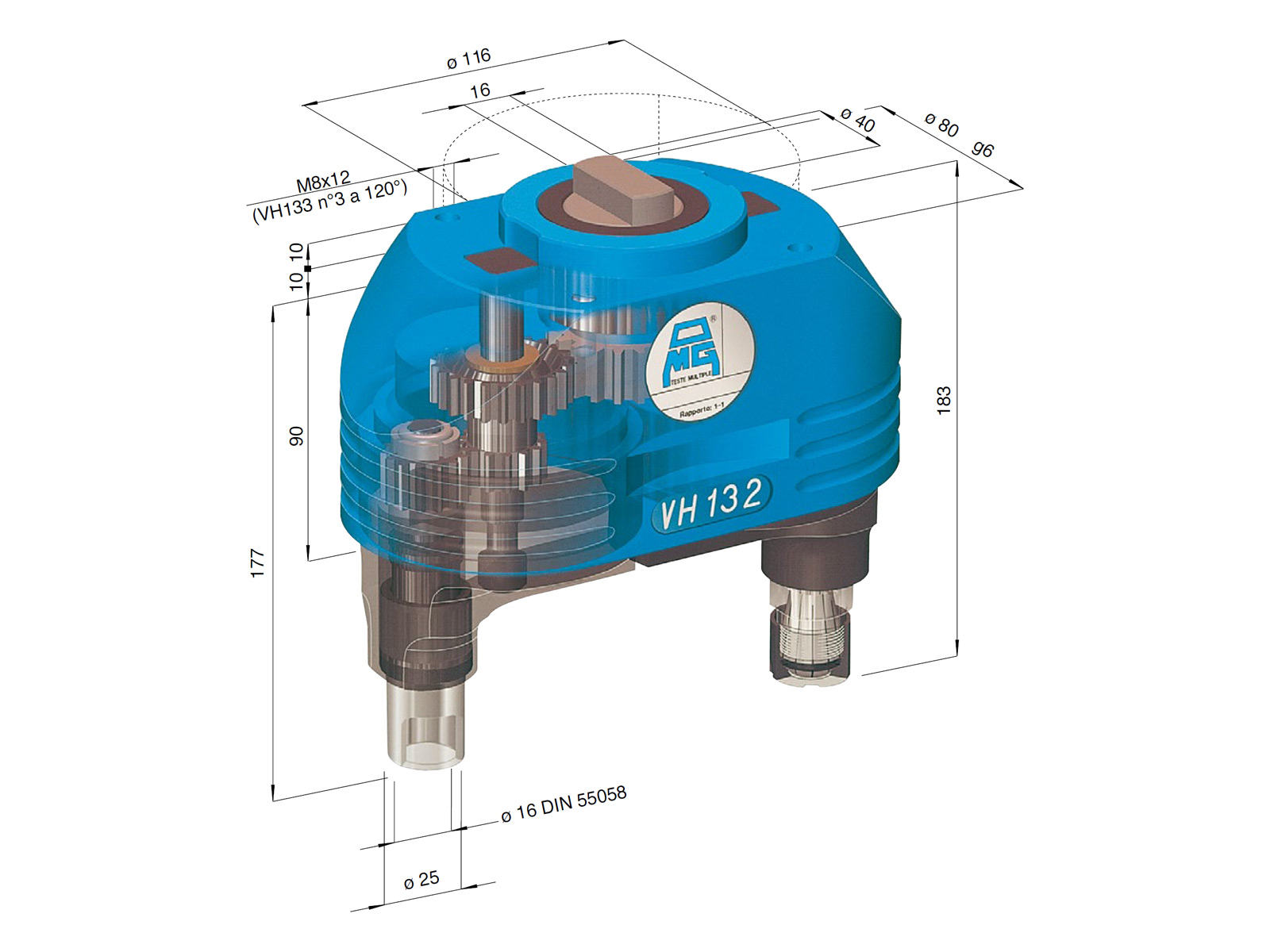

Technical Specifications – VH132

- Item Code: VH132

- Number of Spindles: 2

- Spindle Type: ER25 – max Ø 16 mm

- Center Distance [mm]: 45 + 45

- Maximum Center Distance [mm]: 220

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 16 mm

- Drilling Capacity (Cast Iron GG25): Ø 18 mm

- Tapping Capacity: M12

- Gear Ratio: 1:1

- Maximum Speed [RPM]: 4,000

- Weight [kg]: 6.5

Technical Specifications – VH133L

- Item Code: VH133L

- Number of Spindles: 3

- Spindle Type: ER25 – max Ø 16 mm

- Center Distance [mm]: 45 + 45

- Maximum Center Distance [mm]: 170

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 16 mm

- Drilling Capacity (Cast Iron GG25): Ø 18 mm

- Tapping Capacity: M12

- Gear Ratio: 1:1

- Maximum Speed [RPM]: 4,000

- Weight [kg]: 8.2

VH133

VH134

Technical Specifications – VH133

- Item Code: VH133

- Number of Spindles: 3

- Spindle Type: ER25 – max Ø 16 mm

- Radial Layout: Ø 54 mm spacing

- Maximum Center Distance [mm]: Ø 180

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 16 mm

- Drilling Capacity (Cast Iron GG25): Ø 18 mm

- Tapping Capacity: M12

- Gear Ratio: 1:1

- Maximum Speed [RPM]: 4,000

- Weight [kg]: 8.5

Technical Specifications – VH134

- Item Code: VH134

- Number of Spindles: 4

- Spindle Type: ER25 – max Ø 16 mm

- Radial Layout: Ø 72 mm spacing

- Maximum Center Distance [mm]: Ø 200

- Drilling Capacity (Steel Rm 500 N/mm²): Ø 16 mm

- Drilling Capacity (Cast Iron GG25): Ø 18 mm

- Tapping Capacity: M12

- Gear Ratio: 1:1

- Maximum Speed [RPM]: 4,000

- Weight [kg]: 10.1

| Model | Spindle Count |

Center Distance (Min-Max) |

Drilling Capacity |

Tapping Capacity |

Max RPM |

Weight |

|---|---|---|---|---|---|---|

| VH 042 | 2 | 12 mm – 72 mm | 4 mm | M3 | 4,000 | 0.95 kg |

| VH 043 L | 3 | 12 mm + 12 mm 42 mm + 42 mm |

4 mm | M3 | 4,000 | 1.05 kg |

| VH 043 | 3 | 0 mm – 785 mm | 4 mm | M3 | 4,000 | 1.4 kg |

| VH 044 | 4 | 0 mm – 895 mm | 4 mm | M3 | 4,000 | 1.9 kg |

| VH 062 | 2 | 17 mm – 93 mm | 6 mm | M5 | 4,000 | 1.65 kg |

| VH 063 L | 3 | 175 mm + 175 mm 555 mm + 555 mm |

6 mm | M5 | 4,000 | 1.95 kg |

| VH 063 | 3 | 0 mm – 103 mm | 6 mm | M5 | 4,000 | 2.3 kg |

| VH 064 | 4 | 0 mm – 117 mm | 6 mm | M5 | 4,000 | 3.1 kg |

| VH 082 | 2 | 24 mm – 108 mm | 8 mm | M6 | 4,000 | 2.2 kg |

| VH 083 L | 3 | 24 mm + 24 mm 66 mm + 66 mm |

8 mm | M6 | 4,000 | 2.9 kg |

| VH 083 | 3 | 0 mm – 120 mm | 8 mm | M6 | 4,000 | 3.4 kg |

| VH 084 | 4 | 0 mm – 137 mm | 8 mm | M6 | 4,000 | 4.6 kg |

| VH 102 | 2 | 28 mm – 120 mm | 10 mm | M8 | 3,500 | 3.5 kg |

| VH 103 L | 3 | 28 mm + 28 mm 74 mm + 74 mm |

10 mm | M8 | 3,500 | 4.9 kg |

| VH 103 | 3 | 0 mm – 132 mm | 10 mm | M8 | 3,500 | 4.9 kg |

| VH 104 | 4 | 0 mm – 152 mm | 10 mm | M8 | 3,500 | 7.2 kg |

| VH 132 | 2 | 35 mm – 151 mm | 13 mm | M10 | 3,000 | 5.3 kg |

| VH 133 L | 3 | 35 mm + 35 mm 93 mm + 93 mm |

13 mm | M10 | 3,000 | 7.2 kg |

| VH 133 | 3 | 0 mm – 167 mm | 13 mm | M10 | 3,000 | 7.7 kg |

| VH 134 | 4 | 0 mm – 191 mm | 13 mm | M10 | 3,000 | 10.8 kg |

| VH 181 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 8.3 kg |

| VH 182 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 10.75 kg |

| VH 183 L | 3 | 41 mm + 41 mm 107 mm + 107 mm |

18 mm | M14 | 2,500 | 12 kg |

| VH 183 | 3 | 0 mm – 191 mm | 18 mm | M14 | 2,500 | 15.75 kg |

| VH 184 | 4 | 0 mm – 218 mm | 18 mm | M14 | 2,500 | 19.75 kg |

| VH 201 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 9.2 kg |

| VH 202 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 12.3 kg |

| VH 203 L | 3 | 45 mm + 45 mm 110 mm + 110 mm |

20 mm | M16 | 2,500 | 13.8 kg |

| VH 203 | 3 | 0 mm – 206 mm | 20 mm | M16 | 2,500 | 17.3 kg |

| VH 204 | 4 | 0 mm – 229 mm | 20 mm | M16 | 2,500 | 21.3 kg |

| VH 251 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 10.7 kg |

| VH 252 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 13.7 kg |

| VH 253 L | 3 | 50 mm + 50 mm 110 mm + 110 mm |

25 mm | M20 | 2,000 | 15.7 kg |

| VH 253 | 3 | 0 mm – 229 mm | 25 mm | M20 | 2,000 | 19.7 kg |

| VH 254 | 4 | 0 mm – 253 mm | 25 mm | M20 | 2,000 | 23.7 kg |

How These Devices Attach to the Drill Press

The VH series heads are designed to be compatible with standard pillar drills using several standardized attachment methods to ensure secure and efficient operation. The attachment mechanisms follow DIN standards, which dictate the type of tooling interfaces that can be used. Below is an explanation of the DIN standards that are applicable and how they affect the attachment of the device to the drill press:

Installation and Setup

The VH series heads are designed for quick and easy installation on standard drill presses.

- Quick Installation: Tooling interfaces like collet chucks and drill sleeves allow for rapid installation of the VH series heads. Operators can swiftly change out heads as needed, enabling different operations without significant delays.

- Easy Setup: Once the appropriate attachment method (sleeve, collet chuck, or steep taper) is selected, aligning and securing the VH series head is straightforward. This ensures repeatability in positioning and operational accuracy.

Heavy-duty ER25 multi-spindle drill heads for large-diameter drilling with radial or linear spindle arrangements for industrial production.