- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Notchers for Tube & Pipe

- Pillar Drill Presses / Mill Drills

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Tubes & Pipes End Forming

- Welding Positioners

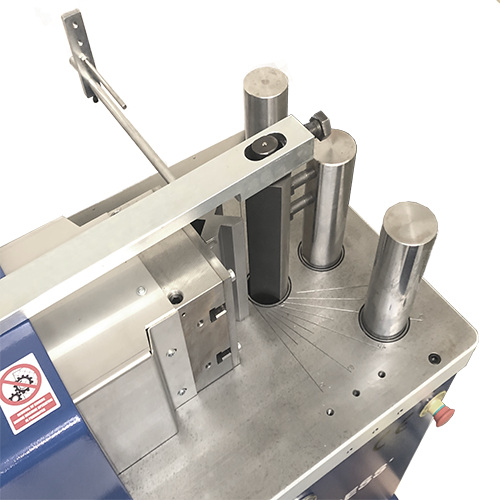

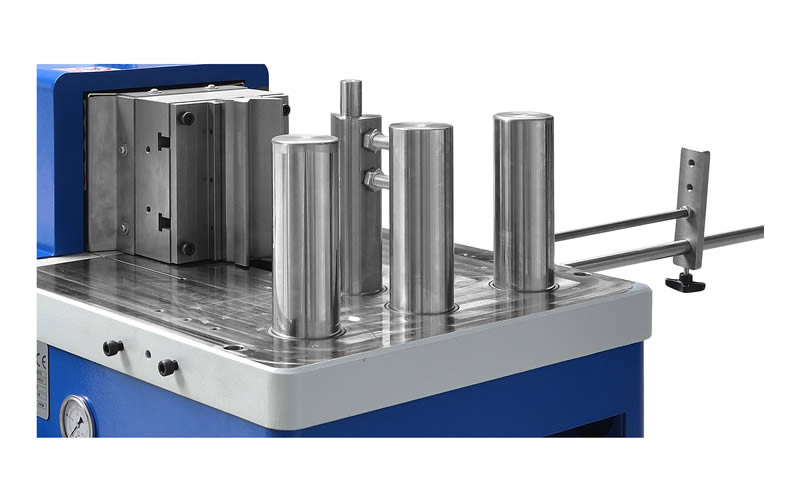

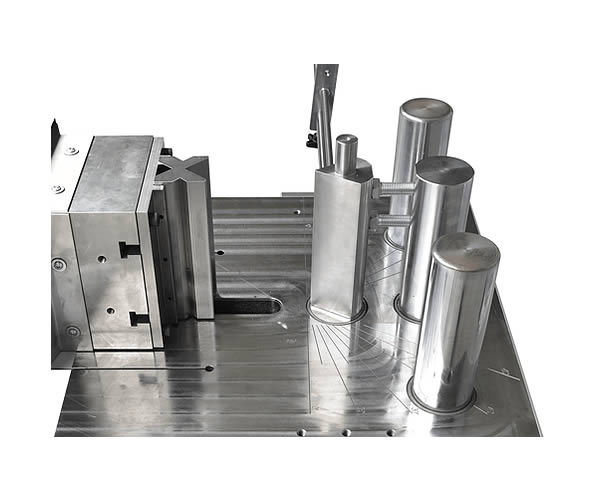

Horizontal Bending Press 80 Ton – NC‑Controlled

Product Code: HB10013-80T-HPBThe Horizontal Bending Press 80 Ton (PPHB‑80NC) is a heavy‑duty, NC‑controlled horizontal hydraulic press built for cold‑metal working tasks such as bending, straightening, notching, cutting and forming. With an 80‑ton capacity, a 300 mm piston stroke, and a modern NC control with up to 100 saved programs, this machine delivers high productivity, precision and versatility. Manufactured in Europe and held in stock for rapid delivery, it is ideal for fabrication shops, production lines and industrial metal‑working operations.

Please contact for prices

- Description

- Additional Info

The PPHB‑80NC horizontal bending press features robust construction and a piston of 200 mm diameter. With a piston stroke of 300 mm, oil delivery of 17.4 l/min and a max working speed of 9.2 mm/sec (return speed 25.6 mm/sec), the machine ensures both force and speed performance.

Equipped with NC‑control, operators can program and store up to 100 working cycles for repeatability and efficiency.

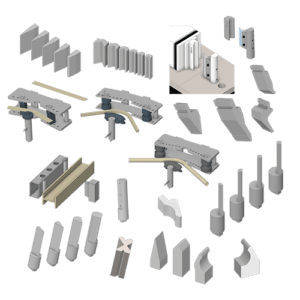

Standard tooling includes a stampholder and back‑gauge, and custom tooling is available to suit specific bending or straightening requirements. The worktable measures 680 × 730 mm, with overall machine dimensions at 1650 × 1005 × 1250 mm and weight around 1900 kg.

This universal hydraulic press is designed to serve a wide variety of cold‑metal working applications, delivering both flexibility and high throughput performance.

Technical Specifications

- Pressure Force [ton]: 80 ton

- Motor Power [kW]: 7.5 kW

- Piston Stroke [mm]: 300 mm

- Piston Diameter [mm]: 200 mm

- Oil Delivery [l/min]: 17.4 l/min

- Max Working Speed [mm/sec]: 9.2 mm/sec

- Return Speed [mm/sec]: 25.6 mm/sec

- Max Pressure [bar]: 250 bar

- Useful Table Size (L × W) [mm]: 680 × 730 mm

- Total Length [mm]: 1,650 mm

- Total Width [mm]: 1,005 mm

- Total Height [mm]: 1,250 mm

- Weight [kg]: 1,900 kg

Key Features

- NC‑control to set piston stroke and store up to 100 programmes

- Selector for manual or semi‑automatic operation

- Flow adjustment valve and pressure control valve for precision

- Integrated pressure manometer for real‑time system monitoring

- Worktable with angular graduation and back‑gauge for versatile tooling setup

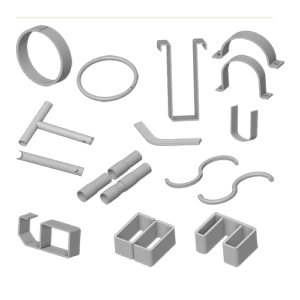

Optional Accessories

- Motorised back‑gauge

- Tool for bending material with large radius

- Accessory for bending rods symmetrically

- Tool for sheet metal forming into specific shape

- Set of stamps and dies tailored to application

80‑ton horizontal bending and straightening press with NC‑control, 300 mm stroke and versatile tooling for cold metal processing.