C-Frame Press • PPCM-100 • 100 Ton • Upper Table • Lower Table • Stroke Control Switch • Foot Pedals

Product Code: 10120-PPCM-100This 100-ton C-frame by RHTC Profi Press is suitable for performing work involving deep-drawing, forming and stamping, riveting, and many other applications. It has a throat depth of 325 mm and a working speed of 6.2 mm/s which is preluded by and an approach speed of 31 mm/s. After the cycle is completed the top plate returns at a rate of 48 mm/s. Maximum stroke of the top plate is 250 mm with the press having an overall shut height of 400 mm.

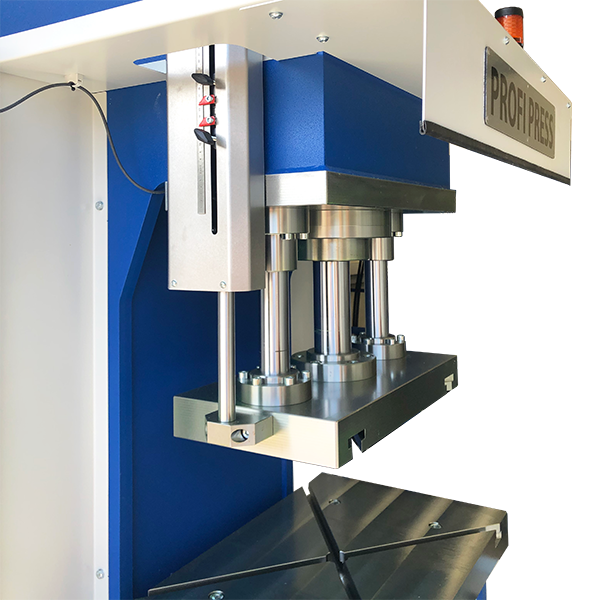

The PPCM C-Frame presses are designed with both an upper table (slide) with dimensions of 650 x 400 mm and lower bolster table with dimensions of 800 x 550 mm incorporating DIN-650 T-grooves which is useful for attaching dies, jigs, fixtures, and tools. Perfect alignment of the upper plate is maintained and ensured by the use of two 50 mm diameter cylindrical guides. The bottom table has a working height of 900 mm.

The PPCM-50 comes with a selector for manual, semi-automatic, and automatic work-modes and it also has two speeds. It also comes outfitted with a pressure switch and the side protection panels are have Level IV light guards installed on them. End of stroke switches facilitates the easy adjustment of the cylinder stroke. All of the RHTC Profi Press C-frame presses are manufactured in Europe according to the latest CE standards and are supplied directly from our warehouse with a CE certificate. All components and materials are of the best possible quality which lends to the machines hefty weight of 3150 kg. This press comes with a standard 2-Year Warranty.

Please contact Workshoppress today with any questions by telephone at +44 (0) 800 999 1090, or by email at info@workshoppress.co.uk.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Force [tn]: 100

- Motor power [kw]: 7.5

- Throat depth [mm]: 325

- Working speed [mm/sec]: 6.2

- Approaching speed [mm/sec]: 31

- Return speed [mm/sec]: 48

- Maximum pressure [bar]: 320

- Piston stroke [mm]: 250

- Guides diameter [mm]: 50

- Lower table (bolster) size [mm]: 800 x 550

- Upper table (slide) size [mm]: 650 x 400

- Daylight Max. [mm]: 400

- Working height [mm]: 900

- Total length [mm]: 1590

- Total width (frontal) [mm]: 1240

- Total height [mm]: 2250

- Weight [kg]: 3150

Features

- Equipped with an upper- and lower table with T-grooves (DIN-650); tools can be easily fastened onto the tables

- Perfect alignment thanks to two lateral guides for the upper table

- Two lateral protection screens (which can be opened) with level IV safety light guards at the front

- The cylinder stroke is easy to adjust with the end-stroke switches

- Manual / semi-automatic / automatic mode

- Two cylinder speeds

- Pressure switch and manometer

- Operation by means of a foot pedal

- Double-Action main cylinder

- Chromed piston

- Hydraulic group has a two-speed high pressure pump

- Hydraulic Group has automatic disconnection of the high speed

- Electro-Valve activation

- Valves include anti-return, safety, and pressure regulation valves

- Cylinder decompression system incorporated

- Safety block preventing slide table from falling

Optional accessories

- Configuration adapted to your requirements

- Higher speeds with a different pump

- Hydraulic ejector placed in the upper- or lower table (or both)

- Hydraulic cushion

- PLC Siemens mod. SIMATIC S7 1200 with 7” touch screen

- Cooling equipment for the hydraulic system

- Larger tables

- Larger vertical Daylight

- Deeper throat depth

- Longer piston stroke

- Custom tools, dies, jigs, and fixtures

- System integrations

Suitable for various materials

C-Frame Presses are useful in every factory or workshop and are not only useful for mild steel but a variety of other materials also such as copper, brass, stainless steel, and carbide. C-Frame presses are used for punching, pressing, coining, straightening, forming, bending and, drawing and are useful in every industry. The RHTC C Frame presses come equipped with standard tools, but custom tools are also available from WorkshopPress.co.uk and we can use our in-house 3D manufacturing capabilities to assist in the design of custom press tools to suit your application.

All of the RHTC Profi Press C-frame presses are manufactured in Europe according to the latest CE standards and are supplied directly from our warehouse with a CE certificate. All components and materials are of the best possible quality which lends to the machines hefty weight of 1750 kg.

CE Certificate

This press comes with a standard 2-Year Warranty and a CE Certificate as standard.

All Profi Presses by RHTC are customisable, integrative, and have custom tools available.

Please contact Workshoppress today with any questions by telephone at +44 (0) 800 999 1090, or by email at info@workshoppress.co.uk.