- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

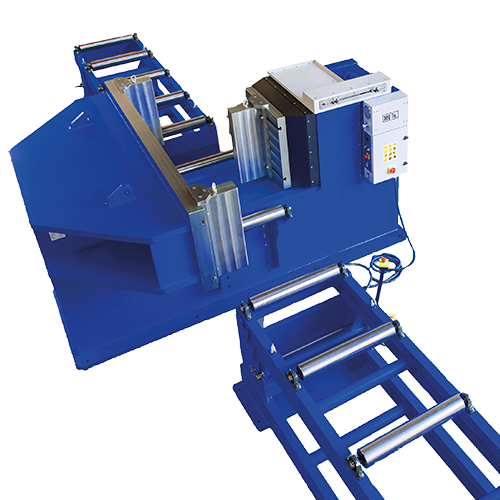

Beam Cambering Press • 150 Ton • Back Table size of 500 x 2000 mm • Pushing Table Size 500 x 500 mm • Throat Depth 300 mm • Guide Columns 50 mm diameter

Product Code: TWPCO-CP-150The 150T Camber Press delivers 150 tons of pressure and has a piston stroke of 450 mm. Piston stroke is regulated utilising end-stroke switches. The maximum opening between the supporting back table and the main pushing table, opening between tables, is 700 mm. The PPHV-150 has a working speed of 2 mm/s and an approach speed of 9.9 mm/s. After the pressing cycle is complete the cylinder retracts at a rate of 15.4 mm/sec. The overall weight of the Cambering Machine is 6700 Kg.

Our 150T Cambering press is built in the EU with nothing but quality materials and components and features and has a framework constructed from S355JR steel that is electro-welded. The Workshop Press Company UK Cambering Machine has a height-adjustable two-sided roller system and the cylinder is double-acting and the hydraulic cambering press include an anti-turning system. The main cylinder uses a chrome piston rod and highly accurate limit switches to regulate the cylinder stroke. The hydraulic unit has 2 speeds integrating an automatic high-speed disconnect mechanism when counter-pressure is sensed by the system as well as a pressure regulator and a gauge that indicates tons of pressure. These Straightening Press machines have an easy to use control panel incorporating a selector for manual or semi-automatic modes and additionally a speed selector for the fast approach and working speed. Forward and backward movements of the cylinder are controlled with low voltage electric pedals.

Our Cambering machines offer a large supporting back table with DIN standard T-Grooves, two heavy-duty support blocks, a main pushing table with four cylindrical lateral guides combined once again with DIN standard T-Grooves and a support block. A combination of the working height and the horizontal design of this cambering machine makes it easy to handle large metal bars, metal profiles, metal beams, large metal tubes, and large metal pipes.

All the machines that WorkshopPress.co.uk offers can be delivered with bespoke options such custom side benches with guide rollers, a larger piston stroke, custom dimensions such as larger vertical daylight, or more advanced controls such as a Siemens NC-control. We can manufacture any hydraulic pressing machine to suit your specifications.

*** Side Roller Table displayed in the picture is an optional extra. ***

Please contact for prices

- Description

- Additional Info

Technical specifications

- Pressure force [kN]: 150

- Motor power [kw]: 4

- Throat depth [mm]: 300

- Working speed [mm/sec]: 2

- Approaching speed [mm/sec]: 9.9

- Return speed [mm/sec]: 15.4

- Pressure max. [bar]: 320

- Piston stroke [mm]: 450

- Guides diameter [mm]: 50

- Opening between tables [mm]: 700

- Supporting back table [mm]: 2000 x 5000

- Pushing main table [mm]: 500 x 500

- Two support blocks back table [mm]: 100 x 100 x 500

- One support block main table [mm]: 100 x 100 x 500

- Working height [mm]: 900

- Total length [mm]: 2520

- Total width [mm]: 2000

- Total height [mm]: 1570

- Weight [kg]: 6700

Features

- Large supporting back table

- Pushing main table

- Support blocks (movable) and T-grooves on both tables

- In height adjustable accompanying roller at both sides of the machine

- Four cylindrical lateral guides for a perfect alignment of the main table

- Adjustable end-stroke switches

- Selector for manual / semi-automatic operation

- Selector for working with 1 or 2 speeds

- Pressure regulator and manometer

Optional accessories

- Supporting back table of 4.000 mm

- Supporting back table of 6.000 mm

- Supporting back table of 8.000 mm

- Basic supply rails (as shown in the picture) with height adjustment (available in different lengths)

- CNC Siemens

- 415 mm folding tool-set (PROMECAN clamping system)

Cambering Press

Cambering is used to add extra structural support to a structural steel profile that covers a wide or long spans with the sole purpose of the camber being to counteract load deflection. Cambering is used in a wide variety of industries and for a wide variety of applications such as bridges, buildings, skyscrapers, churches, lorry trailers, train cars, load-bearing automobiles, ships, airplanes, and rockets.

Structural Steel Cambering is sometimes referred to as an art but the process is very intricate and scientific and a vital process in metal fabrication. When the cambering process is thought of people often think of cambering bigstock such as beams and girders but it can also be used on smaller profiles as well. The most efficient method to carry out cambering, either adding camber or removing camber, is with what is called a cambering machine or cambering press. A cambering press holds a piece of steel in two places then uses hydraulics to apply pressure to a chosen point on the profile, therefore, creating or removing a bend or a camber. Structural enhancement is the primary use of a hydraulic cambering press but sometimes it is simply used to improve the aesthetics of a steel profile.

Structural steel naturally has a camber that denotes a curve in the vertical plane whereas sweep denotes a curve in the horizontal plane. Steel members produced in a steel mill have at least some camber and some sweep and the amount of deviation from straight and the proper and allowable uses of such structural steel is strictly defined by a variety of codes and people usually consider the most import code to be EN 1993 Eurocode 3 that consists of definitions and parameters fo the Design of steel structures and it is made up of 20 sections. RHTC Top-quality hydraulic cambering machines and camber presses will ensure that you can cost-effectively adhere to all manufacturing and building standards and will increase your profitability.

The Profi Press cambering press is built in the EU according to the latest CE-regulations and they come with a 2-Year Warranty.