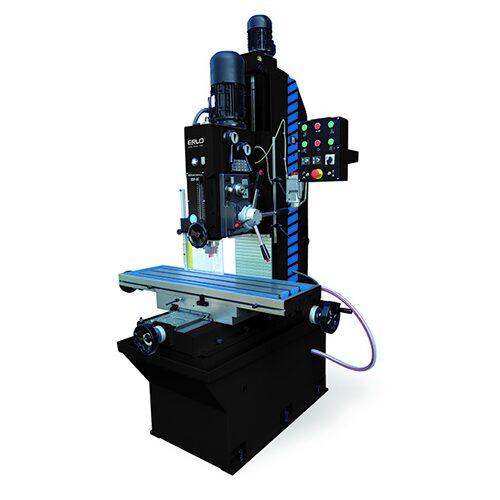

TF Series TF.35 from ERLO • Floor Standing • Auto-Electro-Mag • Gear Drive • Drilling 35 mm • Tapping M35 • Table 360 x 1220 • MT4 • 2.2 kW Motor

Product Code: TF-SERIES-TF-35-ERLOThe ERLO TF Series Prismatic Column Drilling Milling Machines are engineered for precision and durability. These machines are equipped with automatic feed and an electromagnetic clutch, ensuring smooth and efficient drilling and tapping operations. With a drilling capacity of up to 35 mm in steel and a tapping capacity of up to M35, the TF Series is perfect for workshops requiring reliable and accurate drilling solutions. Standard features include motorized headstock displacement, prismatic column, manual greasing pump for guides, column, and table, depth adjustable end, and a frontal wheel for fine sensitive feed. The machines also come with coolant equipment, tool spanning system, lighting equipment, and compliance with CE norms for safety and quality.

Please contact for prices

- Description

- Additional Info

Experience the precision and versatility of the ERLO TF Series Prismatic Column Drilling Milling Machines. Designed for high-performance drilling and tapping operations, these machines feature automatic feed with an electromagnetic clutch and a robust geared drive system. Ideal for metal fabrication and manufacturing, the TF Series ensures accuracy and efficiency in every operation.

Specifications

- Drill capacity (mild steel): 35 mm

- Tapping capacity (mild steel): M35

- Milling capacity (mm): 55

- Transmission: Gear

- Number and range of speeds: (16) 94 – 2225 rpm.

- Feed: Automatic

- Number and range of feeds: (3) 0,10-0,18-0,24

- Clutch: Electro-Magnetic

- Main motor power: 1.2 / 2 Hp

- Main motor speed (rpm.): 750 / 1500 rpm

- Spindle cone: MT4

- Spindle stroke: 180

- Distance spindle to column: 390 mm

- Distance spindle to table: Min 190 / Max 650 mm

- Dimensions of the cross table: 360 x 1220 mm

- Manual cross table stroke (standard): X=700 / Y=360

- Motorized cross table stroke (extra optional equipment): X=650 / Y=350

- Table with T-Slots: Yes

- Tilting table: 45º

- CE Certified: Yes

- Weight: net/gross kg.: 910 / 1400 KG.

- Packaging dimensions and volume: 2520 x 1680 x 711 mm / 7.1 m3

Features

- Gears are Hardened and Ground

- Automatic feed – Electromagnetic clutch

- Geared drive

- Cross table

- Fixed base and displaceable headstock

- Motorized headstock displacement

- Prismatic column

- Guides, Column and table manual greasing pump

- Depth adjustable end

- Frontal wheel for fine sensitive feed

- Coolant equipment

- Tool spanning system

- Lighting equipment

- Main switch

- Emergency push button

- Turning sense selector

- Electrical equipment at low voltage

- Command plate installed in articulated arm

- Drill Guard with Micro-Switch

- CE Certified

Optional Equipment

- Depth DRO (LBC – 50012)

- Tapping System (IR/RS – 50020)

- Automatic Tapping System by lead screw with bracking device (includes one lead screw) (RPF – 50035)

- Additional lead screw, special pitch (HGP-S – 50038)

- Additional lead screw, standard pitch (HGP – 50040)

- Automatic Motorised Longitudinal Feed (ENG X – 50070)

- Automatic Transversal Motorised Feed (ENG Y – 50080)

- DRO – 1 axis (in command plate over an articulated arm) (LDG-1 – 50089)

- DRO – 2 axis (in command plate over an articulated arm) (LDG-2 – 50090)

- DRO – 3 axis (in command plate over an articulated arm) (LDG-3 – 50100)

- Collet holder, set of collets, key, box and locking nut (PPZ – 50120)

- Spindle iso.30 (ISO-30 – 50140)

- Spindle iso.40 (ISO-40 – 50141)

- Automatic tool adjusting for cone iso (SAH – 50170)

- Column prolongation (PRO – 50220)

- Rapid approach and return with pneumatic counterweight (ACNL – 50250)

- Cycle Drilling for Tubes/Profiles (CI – 50255)

High-performance prismatic column drilling milling machines with automatic feed, electromagnetic clutch, and geared drive. Perfect for precision drilling and tapping in metal fabrication.