- Bending, Straightening, Cambering

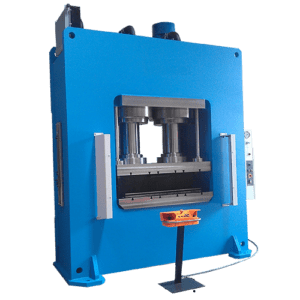

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

500 Ton Bespoke Hydraulic Production Press

Product Code: 500T-Production-BespokeThis bespoke 500 Ton Hydraulic Production Press is tailored to your specific manufacturing needs, offering unparalleled precision and strength for large-scale industrial operations. Constructed with a reinforced electro-welded frame, made from premium S355JR steel, this custom press is designed for high-impact tasks such as heavy-duty stamping, punching, and deep drawing. Every aspect of the press, from its hydraulic system to its control interface, is customizable, ensuring seamless integration with your existing production environment.

Fitted with a bespoke double-acting cylinder and a two-speed motorized hydraulic system, this press provides precision control for even the most complex tasks. The SIEMENS PLC, paired with an advanced 7” touchscreen interface, offers enhanced programmability, allowing operators to set custom stroke lengths, power levels, and dwell times. With expanded storage for over 200 custom recipes, this press is designed for high-efficiency, repetitive production runs, while maintaining the flexibility needed for bespoke manufacturing processes. Safety features, including custom-installed type 4 PLe photoelectric safety barriers, are adapted to your operational needs, ensuring maximum safety and productivity.

Please contact for prices

- Description

- Additional Info

The 500 Ton Special Customised Bespoke Hydraulic Production Press is meticulously designed to meet the unique demands of your production process. Built with enhanced features and customizable configurations, this press is engineered for specific industrial tasks such as deep drawing, stamping, and punching. Manufactured from high-grade electro-welded S355JR steel and capable of operating at pressures up to 320 BAR, this press combines precision and durability to handle the most challenging projects. It seamlessly integrates into bespoke production systems or custom coil feeding and straightening setups offered by Workshop Press Co UK, ensuring optimal workflow and productivity.

Technical Specifications:

- Power: 500 Tons

(customizable pressure settings) - Motor Power: 15 kW

(custom motor configurations available) - Working Speed: 2.4 mm/s

(adjustable to fit specific production needs) - Approaching Speed: 10 mm/s

- Return Speed: 17 mm/s

- Max Pressure: 320 BAR

(custom pressure ranges available) - Piston Stroke: 500 mm

(custom stroke lengths available upon request) - Upper Table Dimensions: 900 x 800 mm

(custom table sizes available) - Lower Table Dimensions: 1,000 x 850 mm

(custom configurations for various applications) - Max Vertical Daylight: 700 mm

(tailored to your specific part requirements) - Frontal Light: 1,150 mm

(can be customized for larger components) - Working Height: 1,000 mm

(custom heights available) - Total Front Dimension: 1,470 mm

- Total Lateral Dimension: 2,585 mm

- Total Height: 3,610 mm

- Guide Diameter: 80 mm

(heavy-duty, precision guides) - Weight: 12,150 kg

(custom frame options for specialized applications)

Features & Uses:

- Bespoke two-speed motorized hydraulic group with custom speed settings to match your production needs.

- Heavy-duty electro-welded structure from S355JR steel, engineered for enhanced strength and precision.

- Customizable guide systems with maintenance-free bimetallic anti-friction bushings for smooth and precise operation.

- Advanced SIEMENS PLC with an upgraded 7” touchscreen for custom programmability and enhanced control.

- Custom safety features, including type 4 PLe photoelectric barriers and bespoke safety integration based on operational requirements.

Industries & Uses:

- Shipbuilding Industry: Bespoke solutions for forming large steel hulls and custom structural components.

- Automotive Industry: Customized deep drawing and heavy-duty stamping for specialized automotive parts.

- Aerospace Industry: Precision forming and punching for complex, lightweight aerospace components.

- Heavy Equipment Manufacturing: Custom forming of massive structural parts for mining and construction equipment.

- Defense Industry: Bespoke fabrication of armored and specialized components for military use.

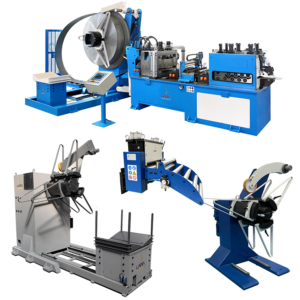

500 Ton Special Customised Bespoke Hydraulic Production Press tailored for large-scale stamping, deep drawing, and punching tasks. Easily integrates into custom production systems and coil feeding and straightening systems designed by The Workshop Press Co UK.