HB-28 Premium 28 Ton Horizontal Press Brake

Product Code: HB10011-HB-28-NCThe Profi Press HB-28 Horizontal Press is a versatile solution tailored for a wide range of metalworking tasks, from bending to straightening, with a robust capacity of 28 tons. This model is designed for precision, featuring adjustable pressure-flow valves that meticulously control hydraulic pressure, impacting both the force and speed of operations. An integrated manometer ensures real-time monitoring of system pressure, enhancing precision in demanding applications.

Equipped with NC-control, the HB-28 offers both manual and automatic modes, providing enhanced control over the cylinder stroke. The ability to store up to 100 programs facilitates repeatable operations for various project requirements. Constructed in Europe, this press meets rigorous standards as it is CE Certified, ensuring compliance with safety and operational guidelines. Available directly from our stock, the HB-28 combines reliability with advanced engineering to meet the diverse needs of modern metalworking environments.

Please contact for prices

- Description

- Additional Info

The HB-28 Horizontal Press is crafted for workshops demanding high precision and efficiency in metal processing. It features a comprehensive control panel for precise operation adjustments and a hydraulic system that delivers consistent force distribution. The inclusion of safety mechanisms and easy-to-replace components makes the HB-28 not only a powerhouse but also a pinnacle of operational safety.

Technical Specifications

- Pressure force [tons]: 28

- System Pressure [bar]: 200

- Motor Power [kW/HP]: 4 / 5.5

- Piston Stroke [mm]: 150

- Piston Cylinder Diameter [mm]: 130

- Oil Delivery [ltr/min]: 8

- Oil Tank Capacity [litres]: 30

- Working Speed [mm/sec]: 2 to 9.8

- Return Speed [mm/sec]: 20

- Tooling Height – Standard [mm]: 200

- Pin Diameters [mm]: 70

- Useful Table Size (L x W) [mm]:

300 x 550 - Bending Capacity Flat Steel [mm]: 200 x 10

- Power Requirements:

400V, 50 Hz, 3-Phase - Total Length [mm]: 1150

- Total Height [mm]: 1103

- Working Width [mm]: 750

- Weight [kg]: 800

Features

- EU Built

- CE Certified

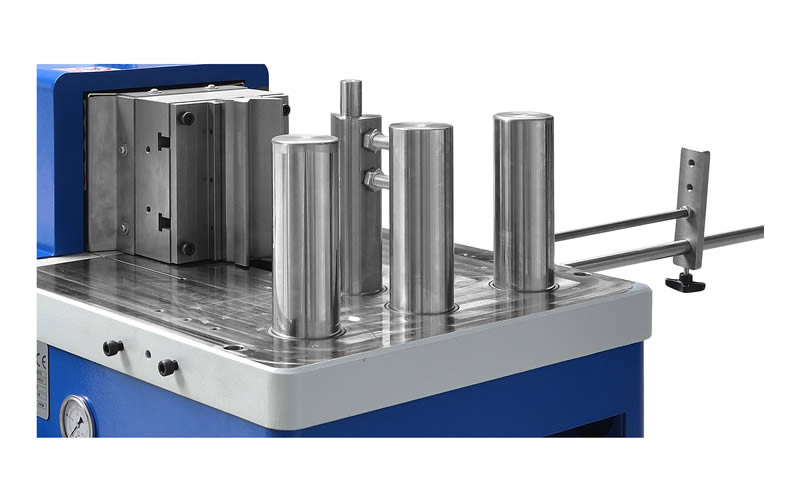

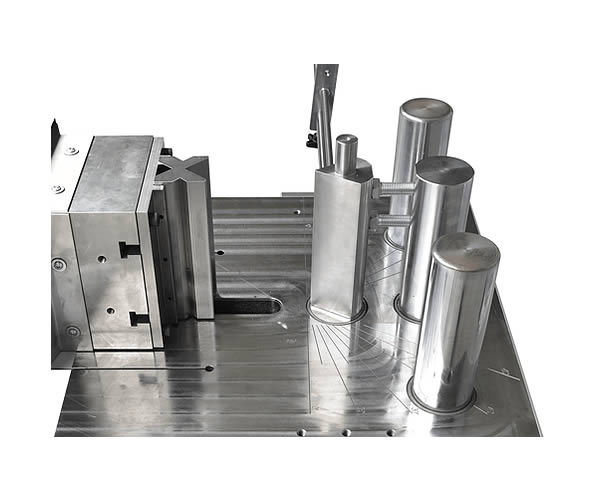

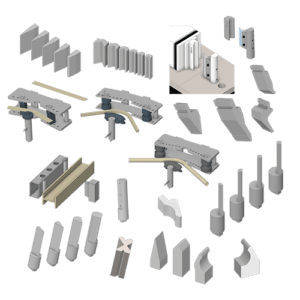

- Standard Tools Included: Multi-Vee Block, V-Die Pin, Cylinder Face with DIN 650 Slots, Tool Holder, Tool Pins (3x), Tie-Bar Strap

Multi-Vee Block

- Openings: Precision-machined at 16, 25, 35, and 50 mm for diverse bending operations.

- Dimensions: Robust build measuring 60 x 60 x 200 mm ensures durability under high operational demands.

Control System

- Schneider ProFace LT4000M Colour Touchscreen: A 145mm intuitive interface that supports operations in 6 languages, enhancing user convenience and accessibility.

- Programmable Controller: Capable of storing up to 100 custom programs with 6 operational steps each, facilitating complex and repetitive tasks.

- Alpha-numeric Program Naming: Allows for easy identification and retrieval of saved programs.

- Advanced Programming Features: Includes control over bending positions, return positions, and dwell times at cycle end, optimizing precision and cycle efficiency.

- Operational Data Tracking: Monitors cycle counts and run times, essential for maintenance scheduling and operational analysis.

Operational Modes

- Manual Mode: Designed for single bends, program adjustments, and tool setting, offering maximum control over each bend.

- Semi-Automatic Mode: Executes production runs from established programs, maximizing throughput and consistency.

Safety and Control

- Emergency Stops (E-Stops): Strategically located push buttons at three locations, including integration into left and right foot pedals, ensuring immediate response in critical situations.

- Flow Adjustment Valve: Allows operators to fine-tune the bending speed, adapting the operation to specific material characteristics.

- Pressure Control Valve with Integrated Manometer: Provides precise control over hydraulic pressure, directly affecting the bending force for optimal material deformation.

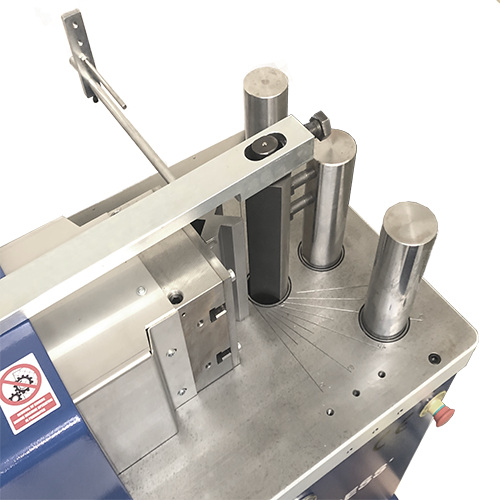

Worktable and Tooling

- Angular Graduated Worktable: Facilitates accurate bend setup with integrated back gauge and scale.

- Versatile Tooling Options: Accommodates a wide array of tooling on the worktable, tool mount, and in the punch and pin holes, enhancing the machine’s versatility for various metalworking tasks.

Integrated Features

- Pressure Control Valve

- Pressure Manometer

- Worktable is equipped with an angular graduation

- Back gauge with Scale

- Pin Holes are lined

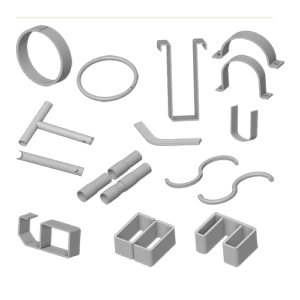

Optional Accessories

- 1-Phase Models

- 60 Hz Models

- Tool for bending material with a large radius

- Tool for bending a rod (symmetrical)

- Tool for bending sheet metal into specific shape

- Several stamps and dies

- Hole Punching

- Tube Notching

- Tube Expanding

- Tube Reduction

- Intricate Bar Shapes for Gates

- Ring Bending

- Round Bar Bending

Maximize your workshop’s productivity with the HB-28 Horizontal Press. Ideal for high-precision bending, profiling, and punching of metal sheets and profiles.