HM SBM-32F AUT Pillar Drill with Geared Head and Auto Tap

Product Code: 06320000SCANTOOL offers a wide variety of top-quality European Gear Driven Pillar Drills models that have drilling capacities ranging from 1 mm to 40 mm. The extensive range of drill presses has a simple construction ensuring high quality, ease of operation, and long life. These industrial drills are designed for industrial use and in addition use top quality components only to guarantee a useful long life. The Scantool Pillar Drills from WorkshopPress.co.uk are competitively priced and designed to last. These models have a 5 Year Motor Guaranty, are CE certified, and come with a separate emergency stop. The SB 40 AUT has an automatic feeding mechanism for hands-free drill and tapping.

Original price was: £4,165.00.£3,850.00Current price is: £3,850.00. (£3,850.00 ex VAT)

- Description

- Additional Info

Technical specifications

- Max. drilling capacity:

32mm - Tapping Capacity:

M16 - Threading in steel & cast iron:

16/22 mm - Column Diameter (ø mm):

125 - Distance spindle center to column surface:

300 mm - Max. distance spindle nose to worktable:

720 mm - Distance spindle nose to the base:

1200 - Spindle taper:

MT4 - Spindle travel:

150 mm - Spindle power feed range:

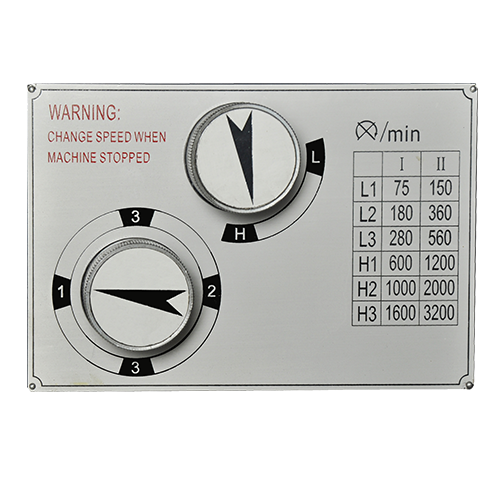

0.10/0.18/0.26mm - Spindle speeds range (option):

75-3200 rpm - Worktable size:

460×460 mm - Dimensions of base:

620×450mm - Width of T-slot:

14mm - T-slot of the working table ( Width X No.):

14mm/2 - T-slot of base ( Width X Distance X No.):

14mm/160mm /2 - Cooling pump:

75W - Motor:

1.1/1.5kW

Included Accessories

- Drilling Machine:

Core unit for precision drilling. - Adapter 2/3 & 3/4:

Ensures compatibility with various drill bits. - Taper Shank for Drilling MT4:

For taper-fit drill bits and tools. - Drilling Chuck:

Holds drill bits, allowing for quick changes. - Tilted Wedge:

Aids in securing the workpiece for angled drilling. - T-Bolt M12×55:

Secures components to the worktable. - Bolt M12×200:

For securing larger setups on the worktable. - Washer 12:

Distributes load under bolt heads. - Nut 12:

Ensures a tight and secure assembly. - Oil Gun:

For lubrication and maintenance of moving parts. - Instruction Manual:

Operation, maintenance, and safety guidelines. - Packing List:

Detailed list of all parts and accessories included.

Technical specifications cont.

- Height and angle adjustable table

- Μoveable table

- Smooth and quiet in operation

- Build-in cooling system

- Powerful motor

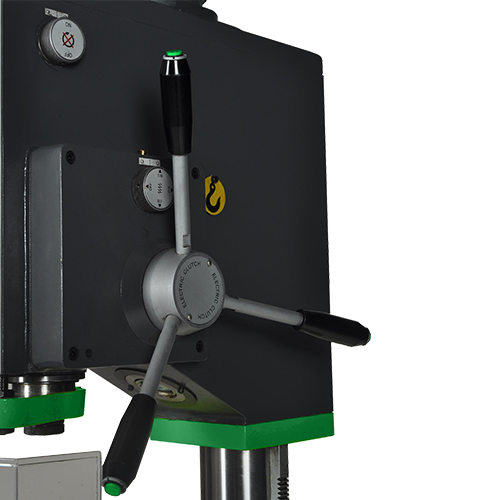

- 3 Spoke handle with electro control of auto-feed and tapping

- Chuck guard c/w micro-switch

- Separate emergency stop

- Built-in working light

- Included drill chuck 16mm – B16

- Automatic tapping device.

Additional Information for SBM-32F-AUT Pillar Drill

The SBM-32F-AUT pillar drill is engineered for precision and durability, designed to meet the needs of both professional and industrial metalworking applications. Below are the key details and features that make this machine an essential tool for your workshop:

Voltage and Phase: Adaptable to standard industrial power supplies, ensuring compatibility with your workshop’s electrical setup.

Operational Safety: Equipped with emergency stop buttons, safety guards, and lock-out features to protect operators during use.

Ease of Use: Features an intuitive control panel and a clear, comprehensive instruction manual, facilitating a smooth operation even for complex drilling tasks.

Versatile Drilling Capabilities: With a drilling capacity of 32mm in steel and cast iron, and a spindle speed range of 75 to 3200 rpm, this machine can handle a wide range of drilling requirements.

Precision Engineering: The MT4 spindle taper and precise spindle travel ensure accurate and repeatable drilling operations.

Robust Construction: Built to withstand rigorous use, the SBM-32F-AUT boasts a sturdy construction and a long-lasting performance.

Warranty and Support: Backed by a manufacturer’s warranty and our dedicated customer service team, ensuring peace of mind with your purchase.

Included Accessories:

Drill chucks, adapter shanks, T-bolts, and more, providing you with a complete set-up out of the box.

An oil gun for regular maintenance, extending the machine’s lifespan and performance.

For more information, detailed specifications, and to view our terms and conditions of sale, please visit our website at Workshop Press Company UK.