- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

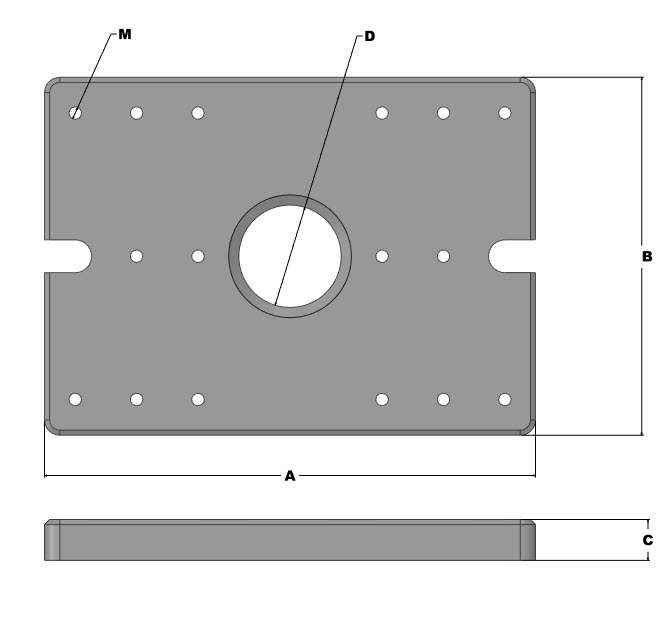

Work Table • Bespoke Configurations and Sizes • Motorised Workshop Presses

Product Code: PSWP-table-BespokeDiscover unparalleled flexibility and precision with our custom-designed work table, crafted for motorised workshop presses. With capabilities extending to 200 ton, 300 ton, and beyond, this table is meticulously engineered to meet the most demanding specifications. Its robust framework and customizable features ensure it integrates seamlessly into any workshop, elevating operational efficiency and the quality of workmanship.

Dimensions

A: Bespoke

B: Bespoke

C: Bespoke

D: Bespoke

M: Bespoke

Weight: Bespoke

Please contact for prices

- Description

- Additional Info

Our bespoke work table is the pinnacle of custom engineering, designed to accommodate any motorised workshop press from 200 ton to 300 ton and other custom specifications. Constructed with unparalleled attention to detail, it guarantees to enhance your workshop’s capability, ensuring that every pressing operation is executed with utmost precision and efficiency. Its sturdy construction and adaptable dimensions make it an indispensable asset for workshops aiming for peak performance.

Technical Features

- Tailor-made dimensions to accommodate any motorised workshop press model.

- Compatible with 200 ton, 300 ton, and custom-configured presses for maximum versatility.

- Engineered with precision for supreme durability and strength.

- Includes 16 M16 mounting holes for flexible tool attachment options.

- Features a 120mm center hole designed for efficient swarf/sludge removal.

- Constructed from premium-grade steel for enduring reliability and performance.

- Simple installation process with seamless integration into existing workshop setups.

- Advanced safety features to safeguard operators during intensive use.

- Exceptional load-bearing capabilities suitable for heavy-duty pressing tasks.

- Modular design principles applied for straightforward upgrades and custom modifications.

Product Uses

- Ideal for complex metal forming and shaping tasks.

- Perfect for the assembly and disassembly of oversized components.

- Facilitates pressing of bearings, bushings, and gears with precision.

- Suitable for bending and straightening operations requiring high force.

- Enables moulding and laminating processes with enhanced accuracy.

- Supports punching and drilling tasks with versatile tool attachments.

- Custom fabrication projects can be undertaken with greater flexibility.

- Prototype development is made easier with adaptable work surfaces.

- Assists in repair and maintenance work for a variety of machinery.

- Useful for educational institutions and training facilities for practical learning.

Elevate your workshop’s capabilities with our bespoke work table, specifically engineered for compatibility with 200 to 300 ton motorised presses and other bespoke configurations. Its customizability ensures an exact fit for any press model, optimizing your operational efficiency and ensuring maximum safety for all user