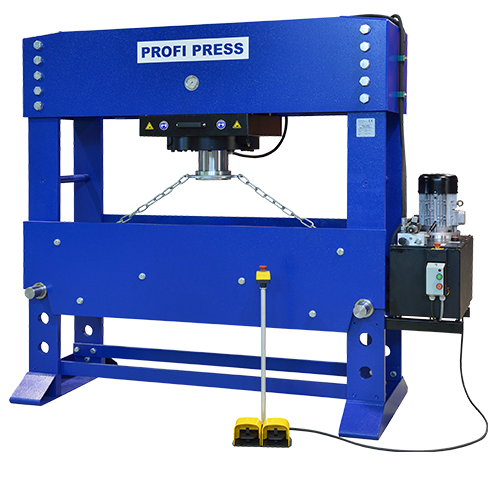

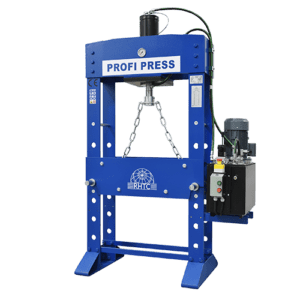

Workshop Press • Foot Pedal or Hand Button Operated • Motorised • Any Tonnage

Product Code: Motorised WSP with Foot Pedal All ModelsExperience the pinnacle of hydraulic workshop press technology with the Workshop Press Motorised Foot Pedal Movable Cylinder. Engineered for precision and efficiency, this press offers unmatched performance in compressing materials for a wide range of applications. Crafted with the highest quality components, it guarantees durability, reliability, and stability, empowering your operations with enhanced productivity and cost-effectiveness. Elevate your workshop, maintenance, manufacturing, or assembly area with this versatile hydraulic press and unlock new possibilities in pressing, forming, folding, straightening, riveting, and more. Invest in excellence with Workshop Press - your partner for superior hydraulic solutions.

Please contact Workshoppress today with any questions at 0800 999 1090, by email at info@workshoppress.co.uk., or complete the quick PRODUCT ENQUIRY form and we will promptly provide you with a no obligation quote.

Please contact for prices

- Description

- Additional Info

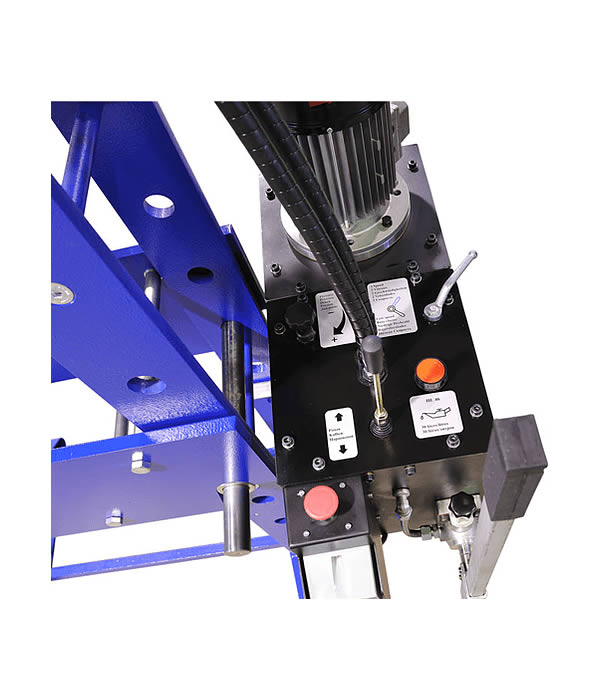

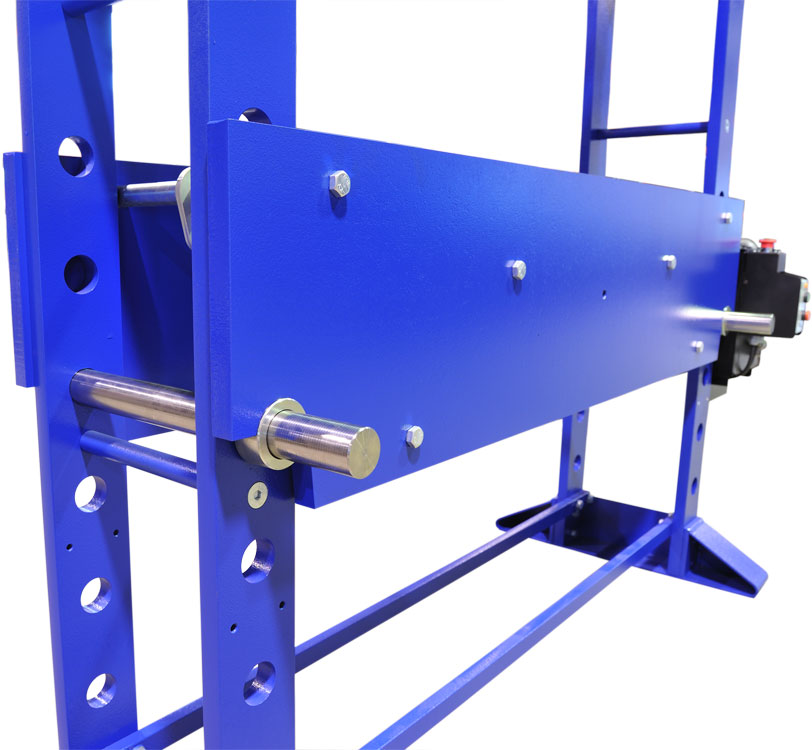

Unlock the full potential of your workshop with the Workshop Press Motorised Foot Pedal Movable Cylinder. This hydraulic workshop press is engineered to deliver exceptional performance and versatility, making it an essential tool for various pressing and forming applications. Whether you’re straightening, folding, or pressing materials, this press offers unmatched precision and efficiency. Built with robust materials and advanced technology, it ensures durability, reliability, and stability, enabling you to maximize productivity while minimizing downtime. With its motorized foot pedal and movable cylinder design, it provides effortless operation and precise control, making it ideal for professional workshops, manufacturing facilities, and assembly lines. Elevate your productivity and efficiency with the Workshop Press Motorised Foot Pedal Movable Cylinder – your ultimate hydraulic solution.

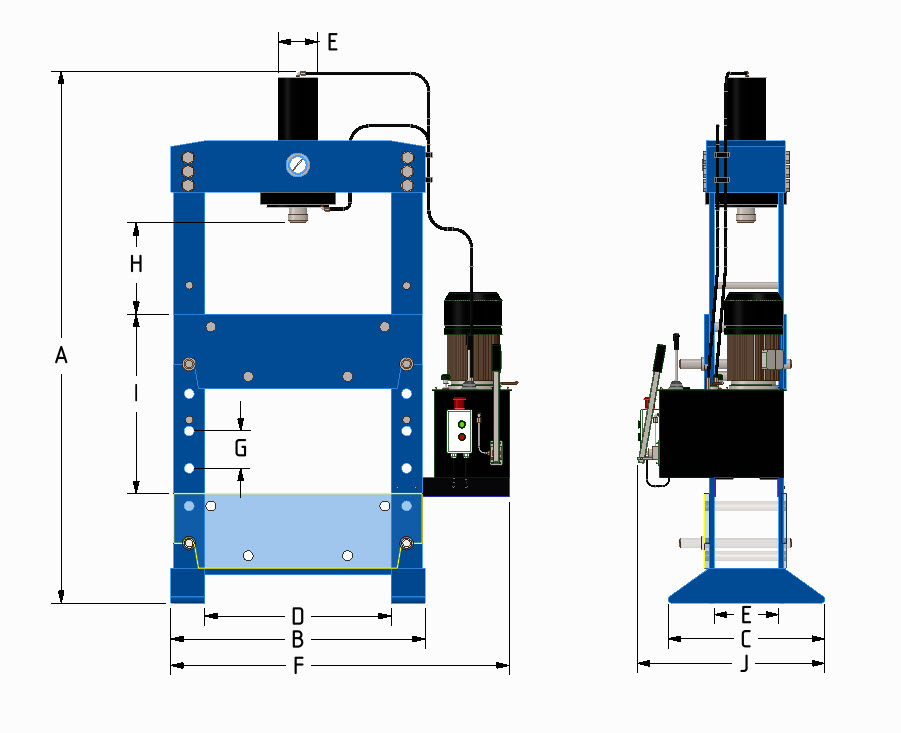

Capacity Table for Foot Operated Workshop Presses.

| Press –> | 30 TON M/H-2 | 60 TON M/H-M/C-2 | 100 TON M/H-M/C-2 | 100 TON M/H-M/C-2 D=1500 | 160 TON M/H-M/C-2 | 160 TON M/H-M/C-2 D=1500 | 200 TON M/H-M/C-2 | 300 TON M/H-M/C-2 D=1750 |

|---|---|---|---|---|---|---|---|---|

| Technical specifications | PP10014FP | PP10028FP | PP10058FP | PP10061FP | PP10083FP | PP10084FP | PP10085FP | PP10090FP |

| Force [kN]: | 294 | 588 | 981 | 981 | 1570 | 1570 | 1962 | 2943 |

| Pressure max. [bar]: | 221 | 259 | 258 | 258 | 255 | 255 | 243 | 260 |

| Stroke [mm]: | 380 | 380 | 380 | 380 | 400 | 400 | 400 | 480 |

| Oil delivery [l/min]: | 2.82 / 11.84 | 2.82 / 11.84 | 5.64/17.2 | 5.64/17.2 | 7.1/27.6 | 7.1/27.6 | 7.1/27.6 | 12/33 |

| Oil capacity [dm³]: | 37 | 41 | 46 | 46 | 57 | 57 | 64 | 100 |

| Press speed [mm/sec]: | 3.57 | 2.07 | 2.47 | 2.47 | 2.4 | 2.4 | 1.84 | 1.8 |

| Lowering speed [mm/sec]: | 9.8 | 8.69 | 7.54 | 7.54 | 7.48 | 7.48 | 5.73 | 4.9 |

| Return speed [mm/sec]: | 18.11 | 10.79 | 9.6 | 9.06 | 9.35 | 9.35 | 7.08 | 6.2 |

| Motor [kW]: | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 3 | 5.5 |

| Voltage [V]: | 400/3 | 400/3 | 400/3 | 400/3 | 400/3 | 400/3 | 400/3 | 400/3 |

| Frequency [hz]: | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| RPM [rpm]: | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 2800 |

| Insulation protection [IP]: | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 |

| Insulation classification: | I | I | I | I | I | I | I | I |

| Movable cylinder: | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Speeds | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Working width [mm]: | 750 | 750 | 1100 | 1500 | 1100 | 1500 | 1300 | 1750 |

| Weight [kg]: | 385 | 540 | 970 | 1145 | 1195 | 1430 | 1690 | 3150 |

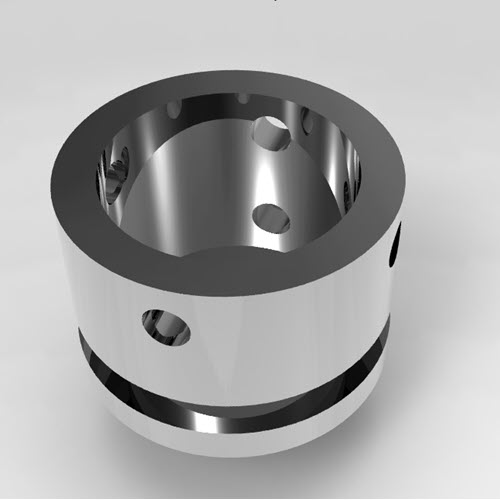

| Diameters | ||||||||

| Inside: | 130 | 170 | 220 | 220 | 280 | 280 | 325 | 380 |

| Piston rod: | 55 | 75 | 90 | 90 | 125 | 125 | 140 | 180 |

| Piston head: | 80 | 100 | 120 | 120 | 160 | 160 | 175 | 215 |

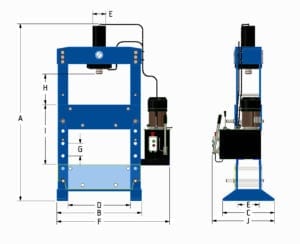

| Diamgram Ref. | ||||||||

| A | 2120 | 2120 | 2140 | 2080 | 2200 | 2270 | 2270 | 2250 |

| B | 1000 | 1000 | 1350 | 1750 | 1410 | 1810 | 1610 | 2120 |

| C | 695 | 695 | 755 | 755 | 825 | 825 | 865 | 985 |

| D | 750 | 750 | 1100 | 1500 | 1100 | 1500 | 1300 | 1750 |

| E | 260 | 260 | 300 | 300 | 380 | 380 | 410 | 500 |

| F | 1315 | 1315 | 1665 | 2065 | 1725 | 2125 | 1925 | 2550 |

| G | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 177 |

| H | 200 | 197 | 180 | 130 | 180 | 180 | 180 | 180 |

| I | 750 | 750 | 750 | 750 | 750 | 750 | 750 | 531 |

| J | 805 | 805 | 865 | 865 | 935 | 935 | 975 | 1085 |

| K | 160 | 200 | 250 | 250 | 325 | 325 | 368 | 420 |

Dimensions refer to above table

Customisations & Modifcations

- 1-Phase Motor

- 60 Hz Motor

- Bespoke dimensions

- System Inetegrations

- Bespoke Applications

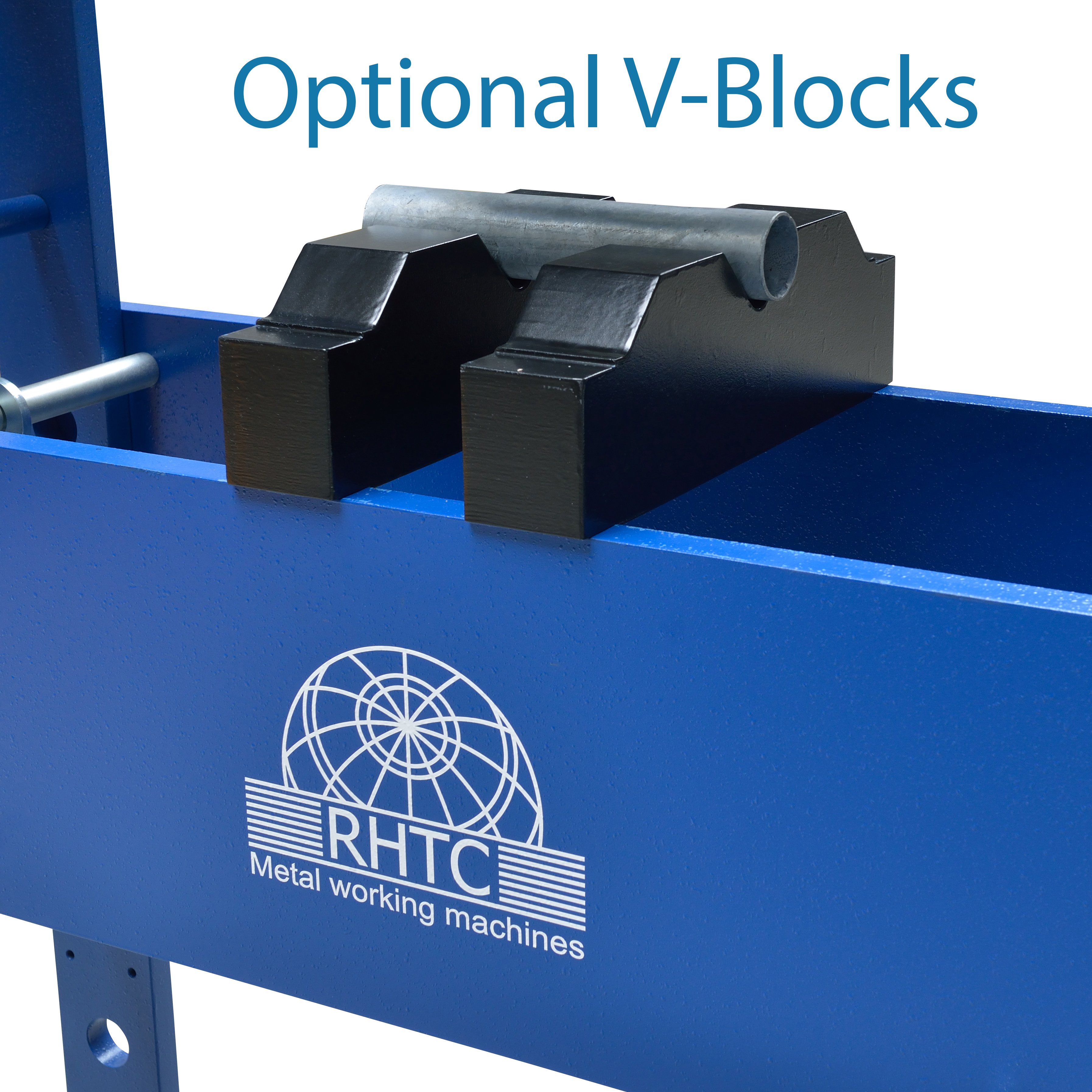

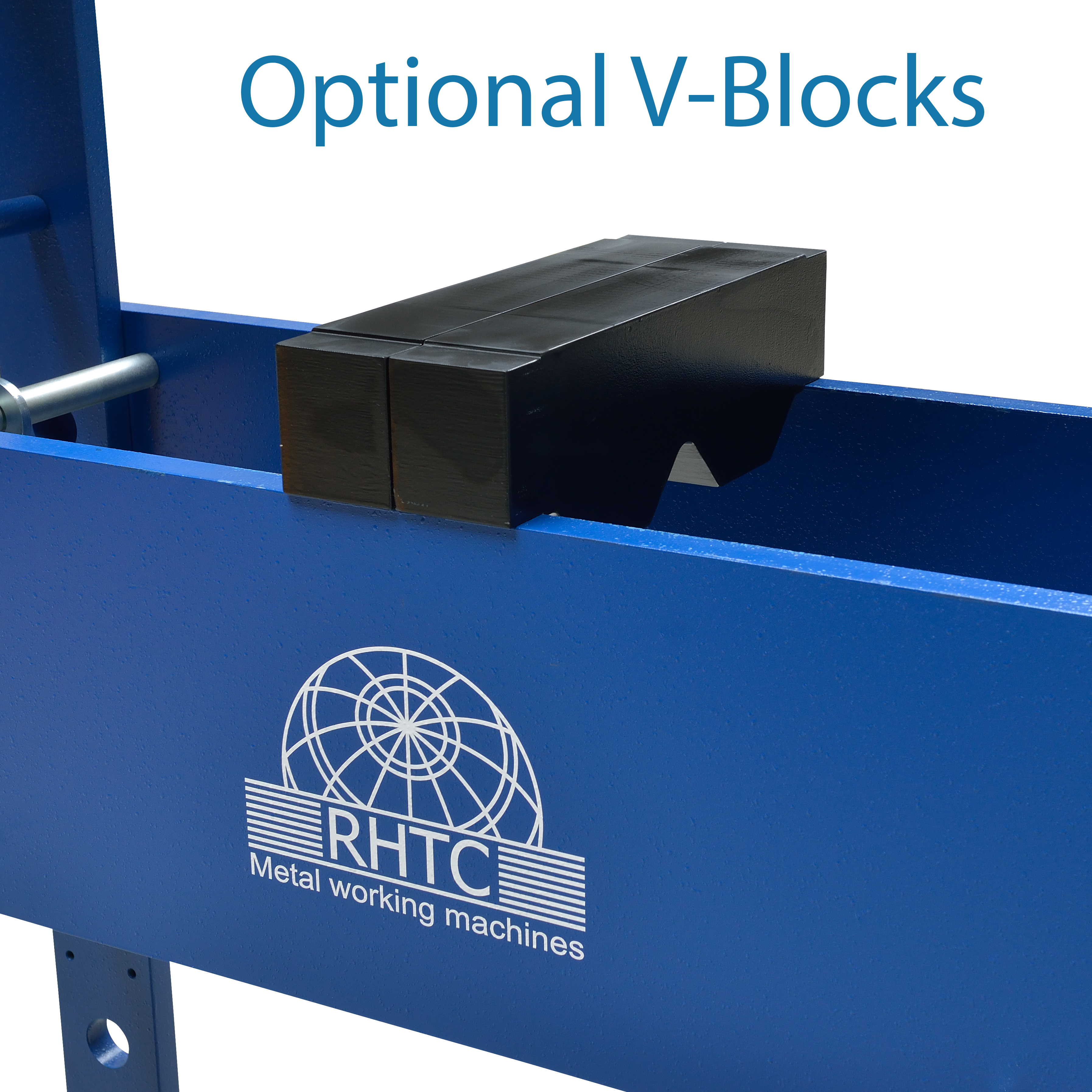

Optional Accessories & Tools

- V-Block sets

- foot pedals

- hand controls

- additional safety features

- system integrations

- mandrel sets

- corner rounding notchers

- corner wedge-shaped punches

- corner notchers

- hole punches of all shapes and sizes

- tube and pipe notching

- drain hole nibbler punch

- brake press tooling

- custom tools

Discover the power of hydraulic presses with WorkshopPress.co.uk’s premium RHTC models. Enhance your operations with top-quality hydraulic workshop presses designed for durability, reliability, and efficiency. From pressing to forming, folding, and riveting, our hydraulic presses empower your business with expanded capabilities and increased profitability. Invest in excellence with Workshop Press today.