- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Notchers for Tube & Pipe

- Pillar Drill Presses / Mill Drills

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Tubes & Pipes End Forming

- Welding Positioners

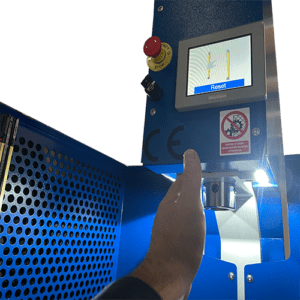

Hydraulic C-frame Press 100 Ton – NC-Controlled Precision Metal Forming

Product Code: PPC10013The PPC-100 Profi Press is a European-manufactured 100-ton hydraulic C-frame press designed for demanding metal forming operations such as cutting, punching, and stamping. Featuring manual and semi-automatic operation, it offers precise stroke control via an NC-controller with 0.1 mm accuracy. Its T-slotted worktable includes a central hole for punching waste, ensuring clean and efficient workflow. With hydraulic adjustment valves and an integrated manometer, this CE-certified press delivers unmatched control, safety, and productivity.

The Profi Press PPC-28 is a versatile hydraulic press designed for precision metalworking. Equipped with an NC controller, it allows digital adjustments of the piston stroke for sub-millimetre accuracy, ensuring consistency in stamping, punching, cutting, and riveting operations. Its robust structure, coupled with a built-in manometer for pressure monitoring, makes it a reliable solution for various industrial applications.

This C-Frame press offers both manual and semi-automatic modes, providing adaptability for different production settings. The lower table features T-grooves for secure tool placement, and the system includes foot pedal operation for ease of use. The press also comes with safety measures like emergency buttons and optional guarding accessories, all designed with CE Certification standards in mind.

Whether used in high-volume production or a more specialized workshop, the PPC-28 guarantees high precision, operational efficiency, and a long service life.

Please contact for prices

- Description

- Additional Info

The PPC-100 Profi Press is a European-manufactured 100-ton hydraulic C-frame press designed for demanding metal forming operations such as cutting, punching, and stamping. Featuring manual and semi-automatic operation, it offers precise stroke control via an NC-controller with 0.1 mm accuracy. Its T-slotted worktable includes a central hole for punching waste, ensuring clean and efficient workflow. With hydraulic adjustment valves and an integrated manometer, this CE-certified press delivers unmatched control, safety, and productivity.

Technical Specifications

- Pressing Force: 100 tons

- Max. Pressure: 250 bar

- Max. Working Speed: 7.6 mm/s

- Piston Stroke: 260 mm

- Working Height: 875 mm

- Vertical Daylight Max.: 450 mm

- Vertical Daylight Min.: 180 mm

- Min. Working Speed: 1 mm/sec

- Return Speed: 12.5 mm/sec

- Piston Diameter: 100 mm

- Piston Tool Hole: 40 mm

- Throat Depth: 320 mm

- Table Size: 780 x 480 mm

- Total Width: 1500 mm

- Total Height: 2200 mm

- Weight (Net): 2900 kg

Features

- 100-ton hydraulic pressing capacity for heavy-duty applications

- NC-Controlled piston stroke for sub-millimeter precision

- Manual and Semi-Automatic modes for versatility

- Adjustable hydraulic pressure and speed for operational control

- Emergency stop buttons for added safety

- Foot pedal operation for ease of use

- High-strength European construction for long-term durability

- CE Certified, meeting European safety and quality standards

- 2-year warranty for reliability

Industries Using and Their Uses

- Automotive: Forming and stamping of heavy-gauge components

- Aerospace: Precision forming of large metal parts for high-stress applications

- Heavy Machinery: Punching and forming thick steel and alloy components

- Oil and Gas: Metal forming for pipeline components and infrastructure

- Power Generation: Punching and forming metal parts for turbines and equipment

100-ton hydraulic C-frame press with NC stroke control, dual operating modes, and precision pressure regulation for metal forming tasks.