- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws

- Belt Grinders

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

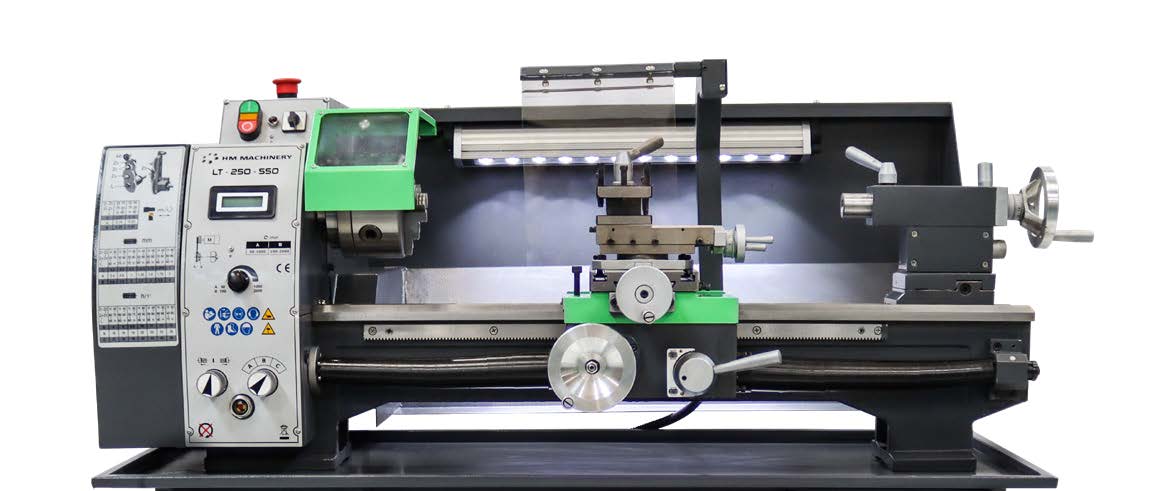

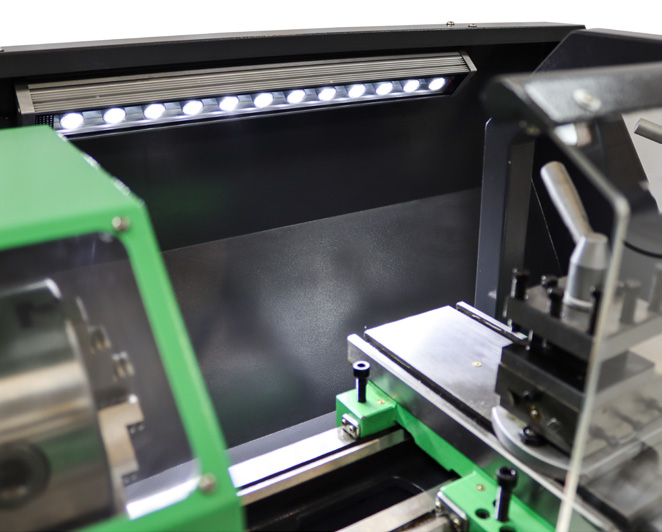

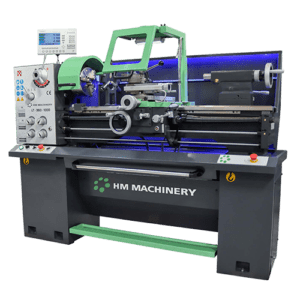

LT 250/550 Precision Metal Lathe • Swing 250 mm • Centres 550 mm

Product Code: 36001012The LT 250/550 from HM Machinery embodies cutting-edge precision in metal lathe design. Equipped with a Ø26mm spindle bore and sophisticated Camlock D1-5 spindlenose, this lathe ensures accuracy across a wide range of machining tasks. Its compact size, variable speed up to 2500 rpm, and precision engineering make it ideal for detailed metalwork in specialized fields such as research and development, instrument making, and fine mechanical tasks.

Experience unparalleled precision and efficiency with our LT 250/550 Industrial Metal Lathe. Designed to handle even the most demanding tasks, this lathe is perfect for industries requiring high accuracy and robust performance. To learn more about how our lathes can transform your machining processes and boost your productivity, check out our detailed guide on precision metal lathes here.

- Description

- Additional Info

Featuring a 250mm swing over bed, 150mm over cross slide, and a comprehensive range of threading capabilities (both metric and imperial), the LT 250/550 is engineered for versatility. Its robust construction includes a 135mm bed width and a precision-engineered tailstock for stability and precision during operations. The machine operates on a 1x230V power supply, making it suitable for workshops with standard power setups.

Features and Uses:

- Swing over Bed: 250mm

- Swing over Cross Slide: 150mm

- Tail Diameter: ø30mm

- Tail Height: 125mm

- Spindlenose: Camlock D1-5

- Distance Between Centers: 550mm

- Width of Bed: 135mm

- Main Spindle:

- Spindle Bore: 26mm

- Taper of Spindlenose: MK-4

- Number of Spindle Speeds: Variable

- Range of Spindle Speeds: 50-2500rpm

- Feeding and Threading:

- Metric Threads: 0.2~4.0mm

- Imperial Threads: 8~56 T.P.I.

- Range of Longitudinal Feed: 0.07~0.40mm

- Cross Slide & Main Slide:

- Type of Toolholder: 4-way

- Max. Travel of Compound Slide: 70mm

- Max. Travel of Cross Slide: 115mm

- Max. Travel of Main Slide: 450mm

- Tailstock:

- Spindle Travel: 80mm

- Taper in Tailstock Spindle: MK-2

- Power:

- Voltage: 1 Phase, 230V, 50 Hz

- Main Motor: 1100 watt

- Dimensions:

- Length: 1200 mm

- Width: 560 mm

- Height: 580 mm

- Weight: 130kg

Features and Uses:

- Precision-engineered for detailed and intricate metalwork: Ensures high precision for applications requiring meticulous detail.

- Variable speed control for versatile machining applications: Allows users to adjust speeds to suit different materials and tasks.

- Compact and robust design, ideal for small workspaces: Perfect for workshops with limited space but requiring high-quality machining.

- Standard 4-way toolholder for operational flexibility: Facilitates quick changes and adjustments, enhancing productivity.

- Ideal for crafting intricate parts: Such as those used in watches, medical instruments, and electronic components.

- Useful in educational settings: Offers practical training for students in technical schools and universities in mechanical and industrial engineering disciplines.

- Supports prototyping and R&D: Essential for developing prototypes in startups and R&D departments in aerospace and automotive sectors.

- Crafting tools and dies: Enables the creation of specialized tools and die sets used in metal stamping and forming.

- Custom jewelry and artistic metalwork: Provides artisans the capability to create detailed, custom designs in metals.

- Maintenance and repair operations: Useful in maintenance departments for repairing and refurbishing mechanical components.

- Essential in industries like aerospace, automotive, and metal fabrication: Where precision metal parts are crucial for both structural integrity and performance.

Compact, precise, and robust – the LT 250/550 metal lathe is designed for professionals seeking unparalleled accuracy in smaller-scale projects.