C-Frame Press • PPCT-250 • 250 Ton • Upper Table • Lower Table • Touchscreen Control

Product Code: PPCT-250The RHTC PPCT-250 model is a 250 ton C-frame press with high speeds, and is designed to carry out tasks involving deep-drawing, stamping and forming in medium and high volumes. Also suitable to incorporate in automated production lines.

The T-Series C-frame presses were designed for high speeds and standard pressing capacities from 30 to 250 tons. Bespoke models are available. The PPCT series C-Frame Presses are designed to carry out metal pressing operations that involve deep-drawing, stamping and forming and is suitable for medium to high volume production runs. The standard configuration is suitable to be incorporated in automated production lines.

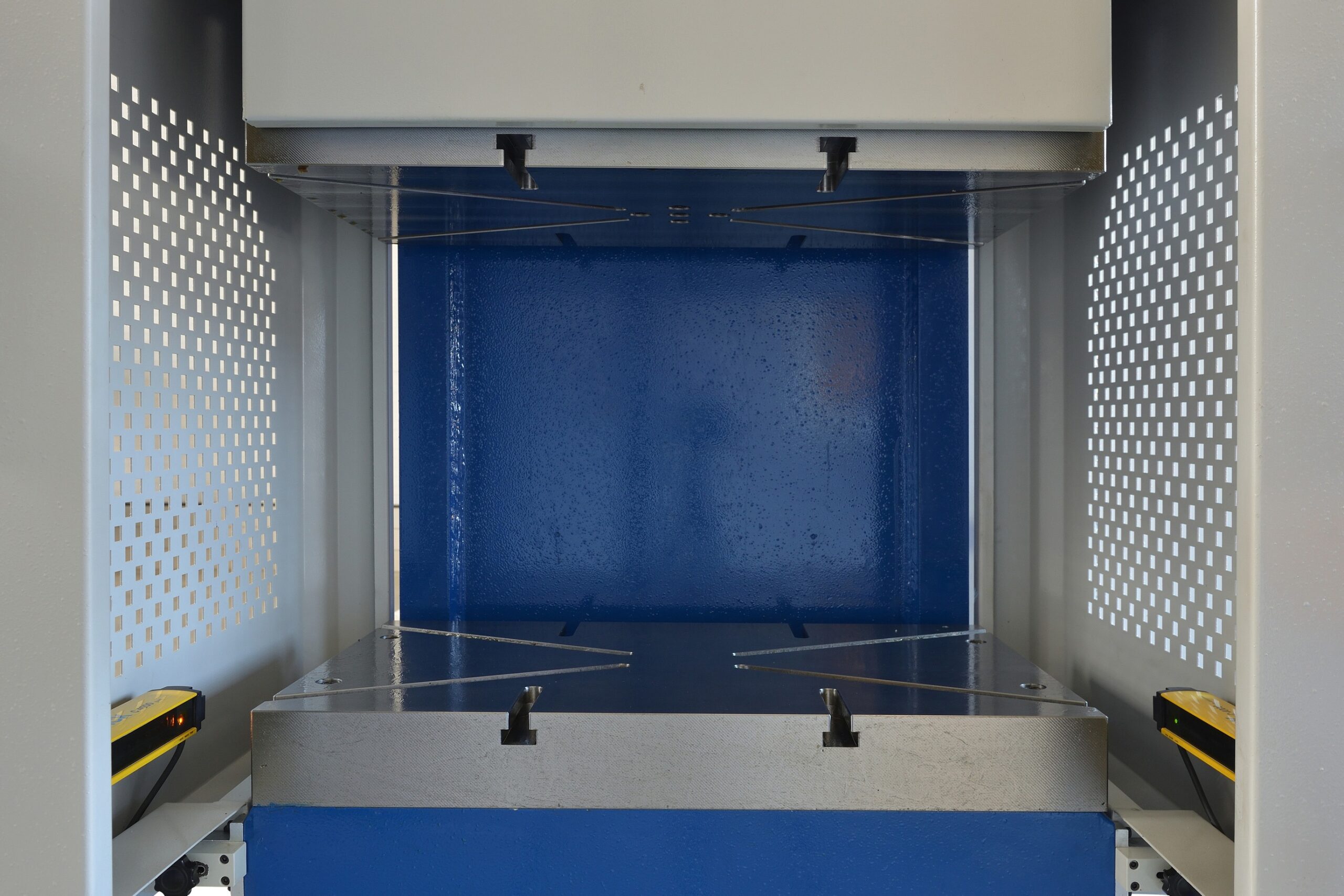

RHTC designed these Profi Press C-Frames with upper- and lower tables with DIN-650 T-grooves for quick and easy mounting of your toolsets. These presses are equipped with a ram cylinder and two auxiliary cylinders to achieve the high speeds. The hydraulic unit has an integrated air-oil cooling system.

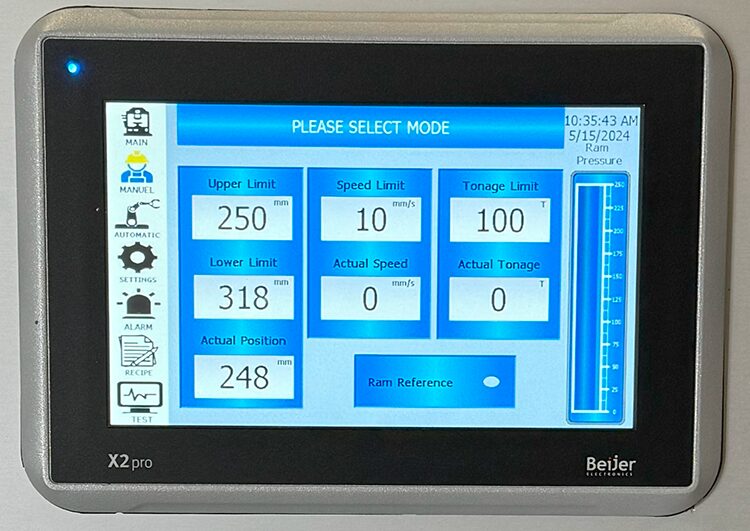

This hydraulic C-frame press with comes with standard sliding side curtains and integrated light curtains. This control system permits programming the power, the cylinder stroke, speeds and pressure-time. The machine operator operates this hydraulic press by means of two-hands push buttons. The PPCT-250 also comes standard with a high quality Beijer X2 pro 7 HMI controller featuring a 7 inch TFT-LCD touch screen with 1.5 GB of application memory. This control system permits programming the tonnage, the cylinder stroke, speeds and pressure-time. The machine operator operates this hydraulic press by means of two-hands push buttons.

All T-Series C-Frame presses are manufactured according to the most current directives and norms and are CE Certified.

See the Additional Info Tab for common questions asked about the PPCT-250 model C Frame Press.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Force [tn]: 250

- Motor power [kw]: 15

- Working speed [mm/sec]: 10

- Approaching speed [mm/sec]: 125

- Return speed [mm/sec]: 180

- Piston stroke [mm]: 400

- Electrical Requirements: 400V, 50Hz, 3-Phase

- Oil Requirement: Shell Tellus 46 or similar

- Oil Requirment [Litres]:

- Electrical Requirements: 400V, 50Hz, 3-Phase

- Table size [mm]: 1000 x 600

- Vertical daylight [mm]: 600

- Total length [mm]: 2100

- Total width (frontal) [mm]: 1900

- Overall height [mm]: 3600

- Weight [kg]: 14000

Features

- Beijer X2 pro 7 HMI Touch Screen control panel to program the pressure, cylinder stroke and the cylinder speeds. With a capacity to save various working cycles

- Lateral protection screens that slide open

- Light guards

- Chrome plated cylinder and a steel welded frame

- Steel Welded Frame

- T-slotted tables

- One main cylinder and two auxiliary cylinders for high speeds

- Hand button dual control operation

- Speed: adjustable and variable and HMI controlled

- Pressure: adjustable and variable and HMI controlled

- Stroke of Piston: adjustable and variable and HMI controlled

- Oil Pressure Gauge

- Air cooling

- CE Certified

- User manual in English

Optional accessories

- Geometry adapted to your requirements (for example larger tables, a larger vertical light or a larger piston stroke)

- HMI with Input and Output ports

- Hydraulic ejector for bottom and side

- Hydraulic cushion

- Variable advance and return speeds

- Single Phase power

- 50 Hz and 60 Hz power

Welcome to the next level of metalworking excellence with our Profi Press C-Frame Press series. While this detailed blog post highlights the capabilities of the 100 Ton C-Frame Press (Model: PPCT-100), the features, processes, and benefits apply to our other PPCT Series C Presses as well. Whether you’re working with a smaller or larger capacity press, you can expect the same precision, power, and efficiency that define the PPCT series. Dive into our comprehensive overview below to discover how these state-of-the-art machines can transform your metalworking capabilities and boost your productivity.

To learn more about the capabilities and advantages of the Beijer X2 Pro 7 HMI controller, read our detailed blog post..

Find out how this advanced controller interacts with the PPCT Series C-Frame presses to enhance precision, efficiency, and operational ease.

Suitable for various materials

C-Frame Presses are useful in every factory or workshop and are not only useful for mild steel but a variety of other materials also such as copper, brass, stainless steel, and carbide. C-Frame presses are used for punching, pressing, coining, straightening, forming, bending and, drawing and are useful in every industry. The RHTC C Frame presses come equipped with standard tools, but custom tools are also available from WorkshopPress.co.uk and we can use our in-house 3D manufacturing capabilities to assist in the design of custom press tools to suit your application.

All of the RHTC Profi Press C-frame presses are manufactured in Europe according to the latest CE standards and are supplied directly from our warehouse with a CE certificate.

This press comes with a standard 2-Year Warranty and a CE Certificate as standard.

All Profi Presses by RHTC are customisable, integrative, and have custom tools available.

Some common questions asked about the PPCT-250 are:

What is the pressing capacity of the PPCT-250?

The PPCT-250 generates 250 tons of force and has working tables that are 1000 mm wide x 600 mm deep. The thickness of material that the press can form is contingent on what type and grade of material are being used and then what the pressing application is. If you require specific information on the presses capabilities please talk to one of our experts.

What is the working area of the PPCT-250?

The PPCT-250 has working tables that are 1000 mm wide x 600 mm and Vertical Daylight of 600 mm. The vertical daylight is the maximum distance between the top slide table and bottom bolster table.

What is the stroke length of the PPCT-250?

The PPCT-250 C Frame Hydraulic press has a maximum stroke of 400 mm.

What is the speed of the PPCT-250?

The PPCT-250 has 3 different speeds, 2 of which are programmable. The 3 speeds are the advance speed which is 125 mm per second, the working speed has maximum of 10 mm per second, and then the return speed is 180 mm per second. The two programmable parameters are the advance speed and working speed.

What is the power of the PPCT-250?

The PPCT-250 can generate a maximum tonnage of 250 tons. The tonnage to be used can be programmed by the press operator.

What is the weight of the PPCT-250?

The weight of the PPCT-250 is 14,000 Kg which is mainly comprised of its heavy duty metal C Frame structure.

What are the dimensions of the PPCT-250?

The footprint of the PPCT-250 is made up of a total length 2100 mm and a total width of 1900 mm. The height of the press is 3600 mm.

What is the warranty on the PPCT-250?

The warranty on the PPCT-250, and most other presses is 2 years.

What are the payment options for the PPCT-250?

Payment options vary depending on the customer’s requirements. For standard presses that are in stock and ready to ship we typically receive payment before release of the machine. For project-based machines structured payments are usually implements with such terms as 60% up front to start the manufacturing process, 30% before shipment, and then 10% upon delivery.

What is the shipping cost for the PPCT-250?

The shipping cost varies quite a bit depending on the location of the customer and then the requirements of the customer. The most economical being a basic delivery where the customer is responsible for offloading the machine. We also offer lifting, placing, connection, and implementations services which will be a more expensive proposition but ensures the machine is in place, setup correctly, and ready to go.

How long will it take to receive the PPCT-250?

All PPCT-250 C Frame Hydraulic Presses are made to order and delivery time, contingent on chosen customer features, will take between 90 and 180 days.